Are you gearing up for an interview for a Cornice Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cornice Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

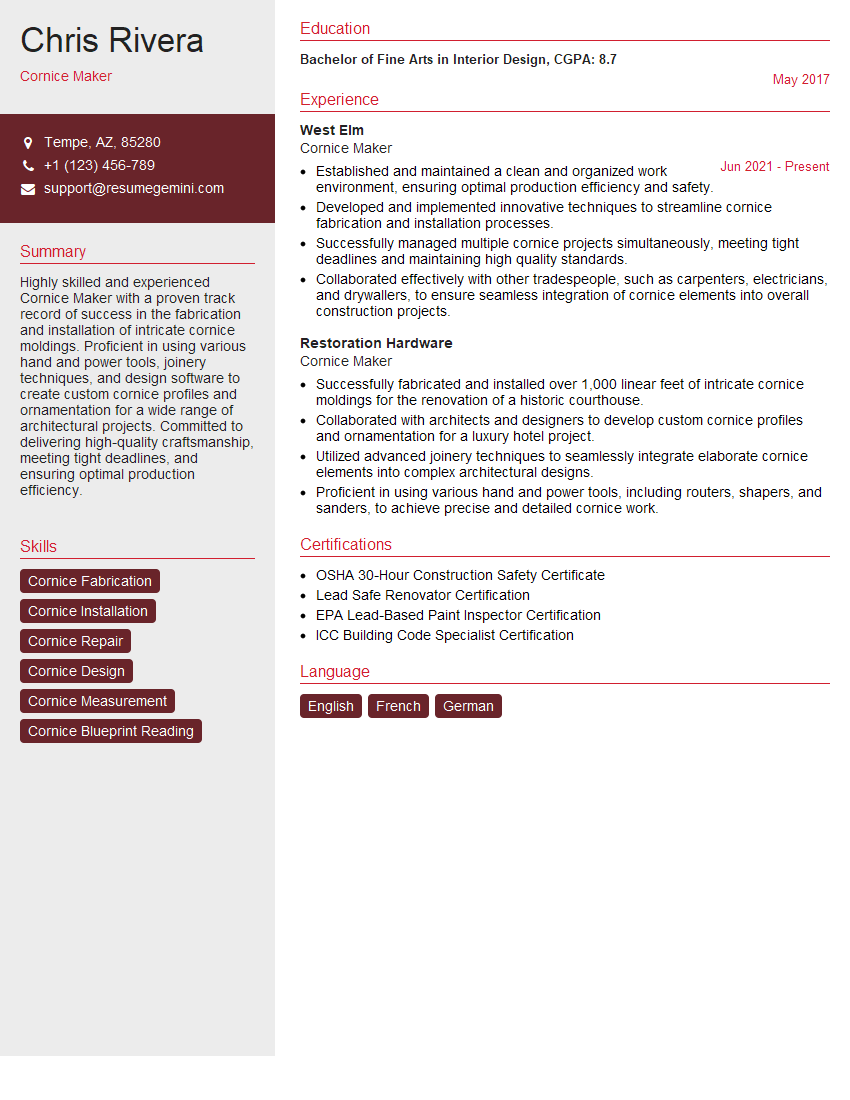

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cornice Maker

1. How do you ensure that the cornice is perfectly level before attaching it to the wall?

Firstly, I assess the area using a spirit level to determine the level. I then use a laser level to project a level line on the wall where the cornice will be attached. The bottom of the cornice is then aligned with the laser line to ensure a perfectly horizontal installation.

2. What materials do you typically use for cornice fabrication?

Gypsum

- Durable and cost-effective

- Can be molded into intricate designs

Wood

- Versatile and available in various species

- Offers warmth and character to the space

Polystyrene

- Lightweight and easy to install

- Can be painted or coated for a customized look

Fiberboard

- Durable and resistant to moisture

- Can be cut and shaped with ease

3. How do you handle complex cornice designs with curves or intricate details?

For complex designs, I utilize a combination of techniques such as:

- Templating and bending with steam or heat

- Creating multiple pieces and joining them

- Using flexible materials like plaster or fiberglass

4. What are the common types of cornice styles and their applications?

Common cornice styles include:

- Cove Cornice: Smooth and curved, providing a classic and elegant look

- Ogee Cornice: A combination of concave and convex curves, offering a more decorative touch

- Crown Cornice: A versatile style with a projecting lower edge and can be highly ornate

- Dentil Cornice: Featuring evenly spaced rectangular blocks, creating a classical and refined appearance

- Egg and Dart Cornice: An elaborate style with alternating egg-shaped and dart-shaped ornaments

5. How do you calculate the quantity of cornice material required for a specific project?

To calculate the quantity, I:

- Measure the length of the walls or areas where the cornice will be installed

- Determine the width and height of the cornice being used

- Calculate the area to be covered and adjust for any necessary overlaps or waste

6. What techniques do you use to ensure a seamless fit between cornice pieces?

For a seamless fit, I employ techniques such as:

- Mitre Cutting: Precisely cutting the ends of cornice pieces at a 45-degree angle to create a clean corner joint

- Coping: Shaping the end of a cornice piece to match the contour of an adjacent surface, ensuring a smooth transition

- Scribing: Measuring and cutting the cornice to fit perfectly against uneven surfaces or curves

7. How do you address uneven walls or ceilings when installing cornice?

To accommodate uneven surfaces, I utilize methods like:

- Shimming: Using thin pieces of material to level the surface before attaching the cornice

- Scribing: Customizing the cornice pieces to match the contours of the uneven surfaces

- Flexible Cornice: Opting for cornice materials that can bend or flex to conform to the irregularities

8. What are the common challenges you encounter during cornice installation and how do you resolve them?

Challenges may include:

Uneven Surfaces

- Using shims or scribing

Complex Designs

- Break down design into smaller sections

Limited Access

- Using scaffolding or ladders safely

Material Handling

- Proper storage and transportation techniques

9. How do you stay up-to-date on the latest trends and techniques in cornice making?

I keep abreast of industry trends through:

- Attending workshops and conferences

- Reading trade publications and online resources

- Consulting with architects, designers, and other professionals

10. What sets you apart from other cornice makers?

My strengths include:

- Attention to Detail: I take pride in producing precise and visually appealing cornices

- Problem-Solving Skills: I can efficiently troubleshoot and find creative solutions to installation challenges

- Customer Focus: I prioritize customer satisfaction and go the extra mile to ensure their needs are met

- Flexibility: I am adaptable to different project requirements and timelines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cornice Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cornice Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cornice Makers are skilled artisans who specialize in the design, fabrication, and installation of decorative moldings and cornices. They are responsible for creating aesthetically pleasing and functional architectural elements that enhance the beauty and value of buildings.

1. Design and Drafting

Cornice Makers work closely with architects and designers to develop design concepts and technical drawings for cornices and moldings. They use specialized software and tools to create detailed plans that specify the dimensions, profiles, and materials used in the construction of these elements.

2. Fabrication and Production

Once the designs are finalized, Cornice Makers use a variety of tools and techniques to fabricate the cornices and moldings. They cut, shape, and join different materials, such as wood, plaster, and fiberglass, to create intricate and durable architectural elements. Some Cornice Makers also specialize in gilding or painting the finished products to enhance their appearance.

3. Installation and Finishing

Cornice Makers work alongside construction crews to install the fabricated cornices and moldings on buildings. They ensure that these elements are securely attached, level, and properly aligned. They also perform touch-ups and finishing work, such as caulking and sealing, to ensure a seamless and visually appealing result.

4. Project Management

Cornice Makers often work on large-scale construction projects and are responsible for managing the execution of their tasks. They coordinate with other trades, oversee timelines, and ensure that the project is completed on time and within budget.

Interview Tips

Preparing for an interview can be daunting, but by following a few simple tips, you can increase your chances of success. Here are some key tips to help you ace your Cornice Maker interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the industry. Learn about their products, services, values, and recent projects. This will show the interviewer that you are genuinely interested in the position and that you have taken the time to prepare.

2. Practice Your Answers

It is helpful to practice answering common interview questions in advance. Think about your skills, experience, and qualifications, and how they align with the job requirements. Prepare specific examples that highlight your abilities and accomplishments.

3. Dress Professionally

First impressions matter. Dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for an office setting. It is also important to have a neat and well-groomed appearance.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic about the job and who have a positive attitude. Show your interest in the position and demonstrate your passion for creating beautiful and functional architectural elements.

5. Ask Questions

Interviews are a two-way street. Asking thoughtful questions at the end of the interview shows that you are engaged and that you are genuinely interested in the position. Ask about the company culture, the challenges and rewards of the role, and the opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cornice Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!