Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Corporate Quality Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

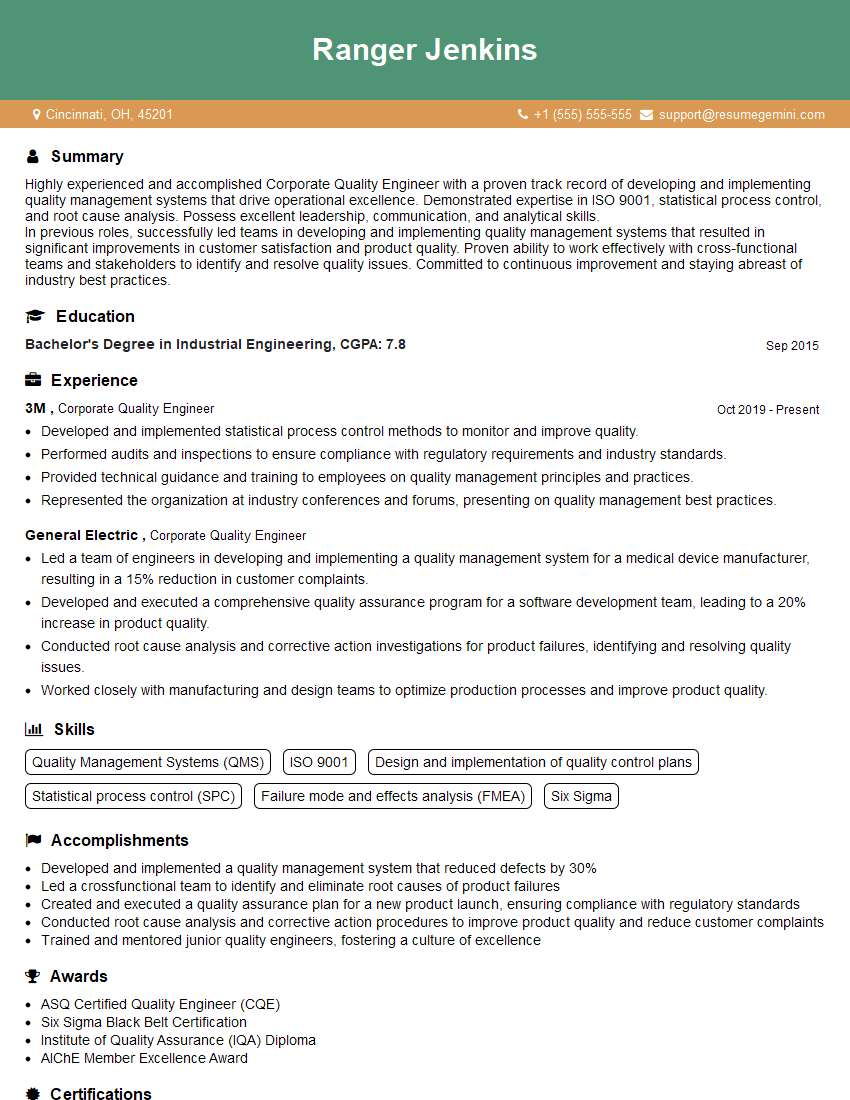

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corporate Quality Engineer

1. Describe the key responsibilities of a Corporate Quality Engineer.

The key responsibilities of a Corporate Quality Engineer include:

- Developing and implementing quality assurance programs to ensure product quality.

- Monitoring and evaluating product quality to identify and correct defects.

- Conducting quality audits to assess compliance with quality standards.

- Working with cross-functional teams to improve product quality and processes.

2. What are the essential skills and qualifications for a Corporate Quality Engineer?

Technical Skills

- Knowledge of quality management principles and methodologies (e.g., Six Sigma, ISO 9001, Agile).

- Proficiency in quality assurance tools and techniques (e.g., statistical process control, root cause analysis).

- Strong understanding of manufacturing and production processes.

Soft Skills

- Excellent communication and interpersonal skills.

- Detail-oriented and analytical mindset.

- Problem-solving and decision-making abilities.

3. What are the different types of quality audits and which ones are most commonly used?

There are various types of quality audits, including:

- Internal audits: Conducted by internal auditors within the organization to assess compliance with internal standards and procedures.

- External audits: Conducted by independent third-party auditors to assess compliance with external standards (e.g., ISO 9001).

- Product audits: Focus on evaluating the quality of a specific product or product line.

- Process audits: Evaluate the efficiency and effectiveness of a specific process or system.

The most commonly used quality audits are internal audits and external audits, as they are essential for ensuring compliance with quality standards.

4. What are the key elements of a quality management system?

- Quality policy: The organization’s overall commitment to quality.

- Quality objectives: Specific, measurable, achievable, relevant, and time-bound goals related to quality.

- Quality procedures: Documented instructions that describe how quality processes are to be carried out.

- Quality records: Data and information that provide evidence of the implementation and effectiveness of the quality management system.

5. What are the benefits of implementing a quality management system?

- Improved product quality and customer satisfaction.

- Reduced costs through defect prevention and process optimization.

- Increased efficiency and productivity.

- Enhanced reputation and competitive advantage.

- Compliance with regulatory requirements.

6. What is the role of Six Sigma in quality management?

Six Sigma is a data-driven methodology used to improve process quality by identifying and eliminating defects. It involves:

- Define: Clearly defining the problem or opportunity to be addressed.

- Measure: Collecting and analyzing data to understand the current state.

- Analyze: Identifying the root causes of the problem.

- Improve: Developing and implementing solutions to eliminate the root causes.

- Control: Monitoring and sustaining the improvements.

7. What are the different types of statistical process control (SPC) charts and when are they used?

- X-bar chart: Used to monitor the central tendency of a process over time.

- R chart: Used to monitor the variability of a process over time.

- p chart: Used to monitor the proportion of defective items in a process.

- c chart: Used to monitor the number of defects per unit in a process.

- u chart: Used to monitor the number of defects per unit of time in a process.

The appropriate SPC chart to use depends on the type of data being collected and the process being monitored.

8. What is the difference between quality control and quality assurance?

- Quality control: Activities performed to ensure that products meet specified requirements.

- Quality assurance: Activities performed to ensure that the quality management system is effective in achieving its objectives.

Quality control focuses on the product, while quality assurance focuses on the system.

9. What are some of the challenges you have faced in your previous quality engineering roles and how did you overcome them?

One of the challenges I faced was implementing a new quality management system. To overcome this, I conducted a thorough assessment of the existing system, developed a detailed implementation plan, and engaged with stakeholders throughout the process to ensure a smooth transition.

Another challenge was dealing with supplier quality issues. I worked closely with suppliers to identify the root causes of the problems and develop corrective actions to prevent future occurrences.

10. Describe a time when you identified a potential quality issue and took action to prevent it from becoming a problem.

In my previous role, I was responsible for monitoring production processes and ensuring product quality. During a routine inspection, I noticed a slight deviation in a critical process parameter. I immediately alerted the production team and initiated an investigation. We were able to identify the root cause of the deviation and implement corrective actions to prevent it from affecting the product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corporate Quality Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corporate Quality Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Corporate Quality Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Corporate Quality Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.