Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Corrosion Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Corrosion Technician so you can tailor your answers to impress potential employers.

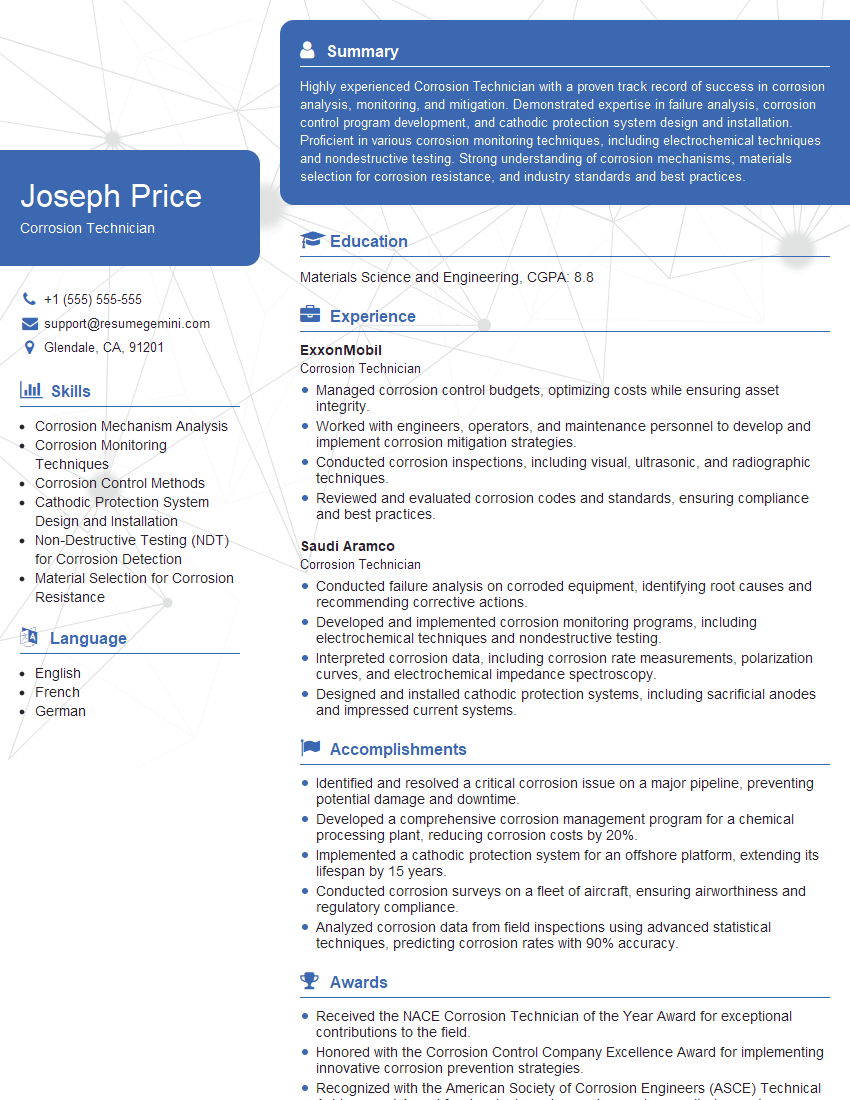

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrosion Technician

1. What are the different types of corrosion?

- Uniform corrosion: This type of corrosion occurs when the entire surface of a metal is attacked by the corrosive environment. It is the most common type of corrosion and can be caused by exposure to moisture, oxygen, and acids.

- Localized corrosion: This type of corrosion occurs when the attack is concentrated on specific areas of the metal surface. It can be caused by factors such as scratches, dents, or the presence of dissimilar metals.

- Stress corrosion cracking: This type of corrosion occurs when a metal is subjected to both a corrosive environment and a tensile stress. It can lead to sudden and catastrophic failure.

- Intergranular corrosion: This type of corrosion occurs when the attack occurs along the grain boundaries of a metal. It can be caused by exposure to certain chemicals or by the presence of impurities in the metal.

2. What are the factors that affect the rate of corrosion?

- The type of metal: Different metals have different corrosion rates. For example, iron corrodes more quickly than aluminum.

- The environment: The corrosive environment can have a significant impact on the rate of corrosion. For example, metals corrode more quickly in the presence of moisture and oxygen.

- The temperature: The temperature can also affect the rate of corrosion. For example, metals corrode more quickly at higher temperatures.

- The presence of other chemicals: The presence of other chemicals in the environment can also affect the rate of corrosion. For example, the presence of salts can increase the rate of corrosion.

3. What are the methods used to prevent corrosion?

- Protective coatings: Protective coatings can be applied to metal surfaces to prevent them from coming into contact with the corrosive environment. These coatings can be made of materials such as paint, plastic, or rubber.

- Cathodic protection: Cathodic protection is a technique that uses an external current to protect a metal surface from corrosion. This current is applied to the metal surface, which makes it less likely to corrode.

- Anodic protection: Anodic protection is a technique that uses an external current to protect a metal surface from corrosion. This current is applied to the metal surface, which makes it more likely to corrode. However, this corrosion is controlled and occurs in a way that does not damage the metal.

4. What are the different types of corrosion tests?

- Immersion testing: Immersion testing involves submerging a metal sample in a corrosive environment for a period of time. The sample is then removed and examined for signs of corrosion.

- Salt spray testing: Salt spray testing involves exposing a metal sample to a salt spray environment for a period of time. The sample is then removed and examined for signs of corrosion.

- Cyclic corrosion testing: Cyclic corrosion testing involves exposing a metal sample to a series of different corrosive environments. The sample is then removed and examined for signs of corrosion.

5. What are the different methods used to measure corrosion?

- Visual inspection: Visual inspection is a simple and inexpensive method for detecting corrosion. It involves examining a metal surface for signs of corrosion, such as rust, pitting, or discoloration.

- Thickness measurement: Thickness measurement can be used to determine the amount of metal that has been lost due to corrosion. This can be done using a variety of techniques, such as ultrasonic testing or eddy current testing.

- Electrochemical testing: Electrochemical testing can be used to measure the rate of corrosion. This involves measuring the electrical potential of a metal surface in a corrosive environment.

6. How do you develop a corrosion control plan?

Planning

- Identify the problem: The first step is to identify the corrosion problem. This involves understanding the environment in which the metal will be used, the type of metal that is being used, and the expected service life.

- Gather data: Once the problem has been identified, it is important to gather data on the corrosion rate. This data can be used to develop a corrosion control plan.

Execution

- Select the appropriate corrosion control method: Once the data has been gathered, the next step is to select the appropriate corrosion control method. This will depend on the type of metal, the environment, and the expected service life.

- Implement the corrosion control plan: Once the corrosion control method has been selected, it is important to implement the plan correctly. This will involve applying the appropriate coatings or treatments to the metal surface.

Monitoring

- Monitor the corrosion rate: Once the corrosion control plan has been implemented, it is important to monitor the corrosion rate. This will help to ensure that the plan is working and that the metal is being protected from corrosion.

- Make adjustments to the plan: If the corrosion rate is not being controlled, it may be necessary to make adjustments to the plan. This may involve changing the corrosion control method or applying additional coatings or treatments to the metal surface.

7. What is the role of a Corrosion Technician?

- Conduct corrosion inspections

- Analyze corrosion data

- Develop and implement corrosion control plans

- Monitor and maintain corrosion control systems

- Provide technical support to other engineers and technicians

8. What are the qualifications for a Corrosion Technician?

- A bachelor’s degree in materials science, engineering, or a related field

- Experience in corrosion testing and analysis

- Knowledge of corrosion control methods and materials

- Excellent communication and interpersonal skills

9. What is the career path for a Corrosion Technician?

- Corrosion Analyst

- Corrosion Engineer

- Materials Scientist

- Technical Manager

- Consultant

10. What are the challenges facing Corrosion Technicians?

- The development of new and more corrosive materials

- The increasing use of corrosion-resistant materials

- The need to reduce the environmental impact of corrosion

- The need to improve the safety of corrosion control systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrosion Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrosion Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corrosion technicians play a critical role in protecting assets from degradation. Their key responsibilities include:

1. Inspect and Monitor Corrosion

Identify and assess corrosion damage on equipment, structures, and pipelines.

- Conduct visual inspections, surface preparation, and non-destructive testing (NDT).

- Collect and analyze data on corrosion rates, environmental conditions, and protective coatings.

2. Develop and Implement Corrosion Control Programs

Design and implement strategies to mitigate and prevent corrosion.

- Specify and apply protective coatings, cathodic protection systems, and other corrosion control techniques.

- Monitor and maintain corrosion control systems, ensuring optimal performance.

3. Provide Technical Support and Recommendations

Offer expert advice and guidance on corrosion-related issues.

- Assist engineers, designers, and maintenance personnel with corrosion prevention.

- Provide recommendations for materials selection, fabrication, and maintenance practices.

4. Stay Up-to-Date on Industry Best Practices

Keep abreast of advancements in corrosion control technologies.

- Attend industry conferences and seminars, and read technical journals.

- Participate in professional organizations and maintain relevant certifications.

Interview Tips

To ace the interview for a Corrosion Technician position, candidates should:

1. Research the Company and Industry

Familiarize themselves with the company’s history, mission, and corrosion-related operations.

- Review the company’s website, annual reports, and social media presence.

- Research industry trends, case studies, and best practices in corrosion control.

2. Highlight Relevant Experience and Skills

Emphasize their experience and expertise in corrosion control techniques and technologies.

- Provide specific examples of corrosion assessment, mitigation, and control projects.

- Demonstrate proficiency in NDT methods, data analysis, and corrosion control software.

3. Prepare for Technical Questions

Anticipate technical questions related to corrosion processes, corrosion control methods, and industry standards.

- Review basic electrochemistry, corrosion mechanisms, and mitigation strategies.

- Study specific corrosion control techniques, such as coatings, cathodic protection, and inhibitors.

4. Show Enthusiasm and Commitment

Express their passion for corrosion control and their desire to contribute to the organization’s success.

- Discuss their interest in the company’s industry and the impact of corrosion on their operations.

- Emphasize their commitment to continuous learning and professional development in corrosion science.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Corrosion Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.