Are you gearing up for a career in Corrugator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Corrugator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

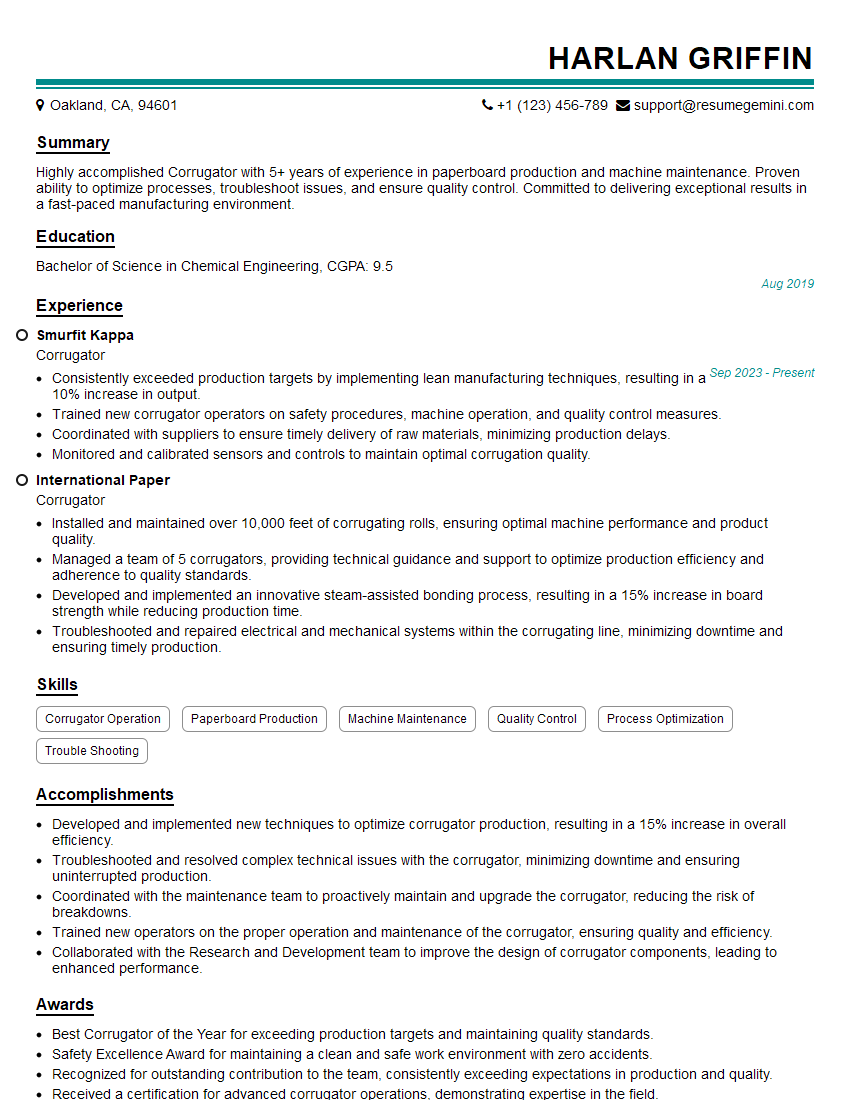

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrugator

1. Describe the fundamental principles of corrugation?

The fundamental principles of corrugation involve the following steps:

- Single Facer: In this process, a continuous sheet of paper known as the linerboard is passed through a series of heated rollers, which form the corrugations or flutes in the paper.

- Double Facer: Here, a corrugated sheet from the single facer is combined with another flat sheet of linerboard. Heat and pressure are applied to bond these layers together, forming a corrugated cardboard structure.

- Corrugator: The combined structure from the double facer is then passed through a series of heated and pressure rollers, further enhancing the bond between the layers and producing various flute profiles, such as A, B, C, D, and E flutes.

2. Explain the different types of flutes used in corrugated board and their applications?

Flute Profiles:

- A-Flute: This is the largest and most commonly used flute, providing high stacking strength and cushioning.

- B-Flute: Slightly smaller than A-Flute, it offers a good balance of strength and printability.

- C-Flute: Smaller than B-Flute, it provides excellent printability and is often used for display graphics.

- D-Flute: The smallest and most flexible flute, it is commonly used for packaging delicate items.

- E-Flute: Even smaller than D-Flute, it offers the highest density and is suitable for lightweight packaging.

Applications:

- A-Flute: Used for heavy-duty packaging, such as appliances and furniture.

- B-Flute: Used for medium-duty packaging, such as food and beverages.

- C-Flute: Used for lightweight packaging and display purposes.

- D-Flute: Used for delicate packaging, such as electronics and glassware.

- E-Flute: Used for lightweight packaging, such as cosmetics and pharmaceuticals.

3. Discuss the factors that influence the quality of corrugated board?

- Paper Quality: The strength and durability of the linerboard and medium paper used impact the overall quality of the corrugated board.

- Gluing Process: Proper application of adhesives during the double facing and corrugating stages ensures a strong bond between the layers.

- Fluting Process: Maintaining the correct temperature and pressure during the corrugating process is crucial for forming consistent and well-shaped flutes.

- Corrugator Machine: The precision and efficiency of the corrugator machine affect the dimensional accuracy and quality of the finished board.

- Environmental Conditions: Factors like humidity and temperature during production and storage can influence the board’s stability and performance.

4. Describe the various testing methods used to evaluate the properties of corrugated board?

- Compressive Strength Test: Measures the resistance of the board to crushing forces applied perpendicular to its surface.

- Edge Crush Test (ECT): Evaluates the strength of the board’s edges when subjected to compression.

- Puncture Resistance Test: Determines the resistance of the board to being punctured by a sharp object.

- Flat Crush Test: Measures the board’s ability to withstand compression forces applied parallel to its surface.

- Water Absorption Test: Assesses the board’s ability to resist moisture penetration.

5. Explain the role of coatings and treatments in enhancing the performance of corrugated board?

- Wax Coatings: Applied to improve moisture resistance and enhance the board’s barrier properties.

- Polymer Coatings: Provide a glossy finish, improve printability, and offer enhanced protection against moisture and abrasion.

- Laminations: Bonding multiple layers of corrugated board or other materials to increase strength, provide additional protection, or enhance aesthetics.

- Anti-Static Treatments: Reduce static electricity buildup, minimizing dust attraction and improving handling.

6. Discuss the environmental considerations associated with corrugated board production and disposal?

- Recyclability: Corrugated board is highly recyclable, contributing to waste reduction and the conservation of resources.

- Biodegradability: The paper used in corrugated board is biodegradable, breaking down naturally over time.

- Sustainable Forestry: Responsible sourcing of paper fibers from sustainably managed forests promotes environmental conservation.

- Waste Minimization: Efficient production processes and proper disposal practices reduce waste generation.

7. Describe the latest trends and advancements in corrugated board technology?

- Digital Printing: Direct printing on corrugated board eliminates the need for pre-printed liners, offering greater flexibility and customization.

- Smart Packaging: Integration of sensors and tracking technologies into corrugated board enables real-time monitoring and data collection.

- Lightweighting: Optimizing board designs and using advanced materials to reduce weight while maintaining strength.

- Sustainable Innovations: Development of biodegradable coatings and adhesives, as well as exploration of alternative fibers to reduce environmental impact.

8. Explain the different converting processes used to transform corrugated board into packaging solutions?

- Die Cutting: Using sharp dies to cut specific shapes and designs into the board.

- Slotting: Creating slots and tabs for assembly and interlocking.

- Scoring: Making weakened lines in the board to facilitate folding and bending.

- Lining: Applying a paper or plastic liner to enhance appearance and functionality.

- Printing and Finishing: Adding graphics, logos, and protective coatings to enhance aesthetics and provide product information.

9. Discuss the key considerations for designing and selecting corrugated packaging solutions?

- Product Protection: Ensuring the board’s strength and protective qualities meet the specific needs of the product.

- Cost-Effectiveness: Optimizing design to minimize material usage and production costs.

- Sustainability: Choosing environmentally friendly materials and designs.

- Branding and Marketing: Utilizing graphics and printing to enhance brand visibility and product appeal.

- Logistics: Considering factors such as stacking strength, size, and weight for efficient shipping and handling.

10. Describe the quality control measures implemented in corrugated board production?

- Raw Material Inspection: Checking the quality of incoming paper and adhesives.

- Process Monitoring: Continuously monitoring production parameters such as temperature and pressure.

- Regular Testing: Conducting performance tests on finished board to ensure it meets specifications.

- Visual Inspection: Manually examining boards for defects and non-conformities.

- Customer Feedback: Gathering feedback from customers to identify areas for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrugator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrugator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

The Corrugator plays a vital role in the production of corrugated cardboard, a material used in various industries. The key responsibilities typically include:

1. Operating Corrugating Machine:

Properly operating the corrugating machine to transform paper into corrugated cardboard.

- Monitoring machine settings and making necessary adjustments to ensure optimal performance.

- Ensuring efficient production by maintaining proper tension and alignment of paper.

2. Quality Control:

Inspecting corrugated sheets to maintain high quality standards.

- Examining sheets for any defects or irregularities, such as tears, wrinkles, or glue issues.

- Implementing corrective actions to address quality concerns.

3. Maintenance and Repairs:

Maintaining and repairing the corrugating machine to prevent breakdowns and ensure smooth operations.

- Performing routine maintenance tasks, such as lubrication, cleaning, and inspection.

- Identifying and resolving minor issues, and reporting major problems to superiors.

4. Raw Material Management:

Managing the supply of raw materials, including paper rolls and glue, to ensure uninterrupted production.

- Monitoring inventory levels and coordinating timely replenishment.

- Ensuring proper storage conditions to maintain the quality of materials.

Interview Preparation Tips

To ace the interview for a Corrugator position, candidates should engage in thorough preparation:

1. Research the Company and Industry:

Gather information about the company’s products, services, and industry trends.

- Visit the company’s website and LinkedIn page.

- Read industry publications and news articles.

2. Practice Answering Common Interview Questions:

Familiarize yourself with potential interview questions and prepare thoughtful responses.

- Prepare answers highlighting your skills, experience, and qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to provide structured examples.

3. Showcase Your Technical Expertise:

Demonstrate your knowledge of corrugating machine operations, quality control techniques, and maintenance procedures.

- Provide specific examples of how you have resolved production issues or improved efficiency.

- Discuss your understanding of different types of corrugating machines and paper materials.

4. Highlight Your Safety Consciousness:

Emphasize your commitment to maintaining a safe working environment.

- Share examples of your adherence to safety protocols and hazard identification.

- Discuss your understanding of industry safety regulations.

5. Prepare Questions for the Interviewer:

Asking thoughtful questions shows interest and engagement.

- Inquire about the company’s growth plans and future projects.

- Ask about the specific responsibilities and expectations of the Corrugator role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corrugator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.