Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cotton Ginner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cotton Ginner so you can tailor your answers to impress potential employers.

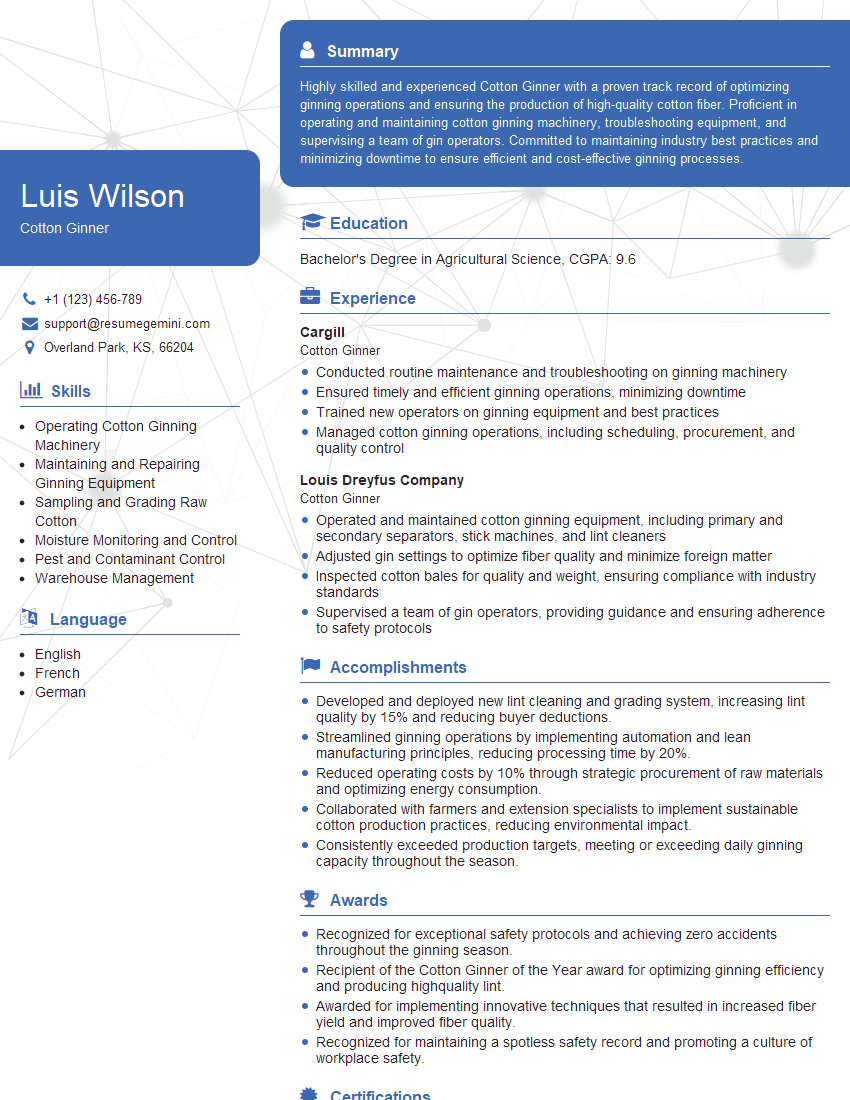

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Ginner

1. What types of cotton ginning systems are commonly used in the industry?

There are two primary types of cotton ginning systems used in the industry:

- Saw ginning system: This system utilizes saw blades to extract cotton fibers from the bolls. It is commonly used for short and medium-staple cotton varieties.

- Roller ginning system: This system employs rollers to separate cotton fibers from the bolls. It is suitable for long-staple cotton varieties, preserving the fiber length and quality.

2. Explain the process of cotton ginning from harvesting to baling.

Harvesting and Collection

- Cotton bolls are mechanically harvested using cotton pickers.

- The harvested cotton is transported to gins for processing.

Ginning Process

- The cotton is passed through a cleaner to remove impurities and trash.

- The bolls are then processed using saw or roller gins to separate the fibers from the seeds.

- The separated fibers are cleaned to remove any remaining impurities.

Baling and Storage

- The cleaned fibers are pressed into bales using hydraulic presses.

- The bales are wrapped and secured for storage and transportation.

3. What are the key factors that affect the quality of ginned cotton?

The quality of ginned cotton is influenced by several factors, including:

- Fiber length and strength: Longer and stronger fibers produce higher-quality yarn.

- Micronaire: A measure of fiber fineness, affecting yarn quality and fabric softness.

- Color and cleanliness: Whiter and cleaner cotton fetches a premium.

- Moisture content: Optimal moisture levels ensure fiber integrity and prevent damage.

- Ginning equipment and settings: Proper calibration and maintenance of ginning machinery are crucial.

4. Describe the different methods used for lint cleaning and purification.

Lint cleaning and purification are essential for removing impurities and improving fiber quality. Common methods include:

- Mechanical cleaning: Uses screens and air currents to remove trash and debris.

- Pneumatic cleaning: Employs air suction to separate fibers from impurities.

- Electrostatic cleaning: Uses electrical charges to attract and remove dust and fine particles.

- Optical sorting: Identifies and removes discolored or damaged fibers using sensors.

5. How do you ensure consistent quality in ginned cotton?

Maintaining consistent quality requires adherence to best practices throughout the ginning process:

- Raw material selection: Inspecting cotton for quality before ginning.

- Proper ginning settings: Calibrating and maintaining ginning equipment for optimal performance.

- Quality control: Regularly testing and monitoring ginned cotton to meet desired quality standards.

- Traceability: Tracking cotton from harvesting to ginning to ensure quality throughout the supply chain.

6. What are the safety hazards and precautions in cotton ginning operations?

Cotton ginning involves the following safety hazards:

- Machinery hazards: Moving machinery, electrical equipment, and high-pressure systems.

- Cotton dust: Respirable cotton dust can cause respiratory issues.

- Fire hazards: Cotton is highly flammable, requiring proper fire prevention and control measures.

Precautions include:

- Machine guarding and safety protocols.

- Dust control systems and personal protective equipment.

- Fire detection and suppression systems.

- Regular safety training for employees.

7. Describe your experience in troubleshooting and maintaining cotton ginning equipment.

In my previous role, I was responsible for troubleshooting and maintaining cotton ginning equipment:

- Problem identification: Analyzing machine performance, identifying error codes, and assessing potential causes.

- Repair and maintenance: Implementing repairs, replacing components, and adjusting settings to restore equipment functionality.

- Preventive maintenance: Conducting regular inspections, lubrication, and adjustments to minimize equipment downtime.

- Collaboration with technicians: Consulting with other technicians and engineers for complex issues.

8. How do you stay updated on the latest technologies and advancements in cotton ginning?

I keep abreast of the latest technologies and advancements in cotton ginning through various channels:

- Industry conferences and seminars: Attending industry events to learn about new developments.

- Trade publications and research journals: Reading specialized publications and research papers.

- Networking with peers and experts: Connecting with professionals in the field to exchange knowledge.

- Online research and webinars: Utilizing online resources and industry webinars to stay informed.

9. What are your suggestions for optimizing the efficiency and profitability of a cotton gin?

Optimizing efficiency and profitability in cotton ginning involves implementing the following strategies:

- Maximize ginning capacity: Ensuring optimal machine utilization and minimizing downtime.

- Improve fiber quality: Utilizing advanced lint cleaning and purification techniques to enhance fiber quality and value.

- Reduce operating costs: Implementing energy-efficient practices and optimizing supply chain management.

- Increase revenue: Exploring value-added services such as specialized fiber sorting and packaging.

- Adopt technology: Utilizing automation and data analytics to improve decision-making and efficiency.

10. How do you manage a team of gin operators to achieve production targets and quality standards?

Effective team management in cotton ginning involves implementing the following strategies:

- Clear communication: Establishing clear roles, responsibilities, and performance expectations.

- Training and development: Providing comprehensive training and skill development opportunities.

- Motivation and recognition: Recognizing and rewarding team achievements and contributions.

- Performance monitoring: Regularly tracking progress towards targets and identifying areas for improvement.

- Collaboration and teamwork: Fostering a collaborative and supportive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Ginner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Ginner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cotton Ginner is responsible for managing a cotton ginning facility and overseeing the separation of cotton fibers from the cottonseed. The key responsibilities include:

1. Ginning Operations

Supervising cotton ginning processes, including the operation, maintenance, and repair of ginning equipment.

- Ensuring optimal ginning performance to maximize cotton yield and quality.

- Monitoring cotton quality throughout the ginning process and making adjustments as needed.

2. Seed and Lint Management

Managing the handling and storage of cottonseed and lint, ensuring their quality and preventing contamination.

- Supervising the cleaning, drying, and storage of cottonseed to maintain its viability for planting.

- Organizing the packaging and storage of cotton lint to preserve its quality and value.

3. Safety and Maintenance

Enforcing safety regulations and maintaining a safe working environment in the ginning facility.

- Inspecting and maintaining ginning machinery to ensure its safe operation and prevent breakdowns.

- Conducting regular safety drills and training sessions to enhance employee awareness and reduce accidents.

4. Quality Control and Regulatory Compliance

Ensuring the adherence to quality standards and regulatory requirements in all ginning operations.

- Implementing and maintaining quality control systems to monitor cotton fiber and seed quality.

- Complying with industry regulations and environmental standards related to cotton ginning.

Interview Tips

To ace an interview for the Cotton Ginner position, it is essential to prepare thoroughly and demonstrate your knowledge and skills.

1. Research the Industry and Company

Familiarize yourself with the latest advancements in cotton ginning technology, industry trends, and the specific operations of the company you are applying to.

- Read industry publications, attend trade shows, and conduct online research to stay up-to-date.

- Visit the company website and social media pages to learn about their history, mission, and values.

2. Highlight Your Ginning Experience and Skills

Showcase your previous experience in cotton ginning operations, including equipment handling, seed and lint management, and quality control.

- Quantify your accomplishments using specific metrics, such as increased cotton yield or improved lint quality.

- Emphasize your technical expertise in ginning machinery, safety protocols, and regulatory compliance.

3. Demonstrate Leadership and Management Abilities

As a Cotton Ginner, you will be responsible for leading a team and managing daily operations. Highlight your leadership skills, conflict resolution abilities, and commitment to employee development.

- Share examples of how you have successfully managed teams, motivated employees, and resolved workplace conflicts.

- Discuss your plans for enhancing employee productivity and fostering a positive work environment.

4. Emphasize Your Safety and Quality Focus

Cotton ginning involves potential hazards and strict quality requirements. Highlight your commitment to safety and quality by providing examples of your previous safety initiatives and quality control measures.

- Describe how you have implemented safety programs, conducted risk assessments, and ensured compliance with safety regulations.

- Explain your understanding of cotton quality standards and your strategies for maintaining them throughout the ginning process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cotton Ginner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.