Feeling lost in a sea of interview questions? Landed that dream interview for Cotton Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cotton Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

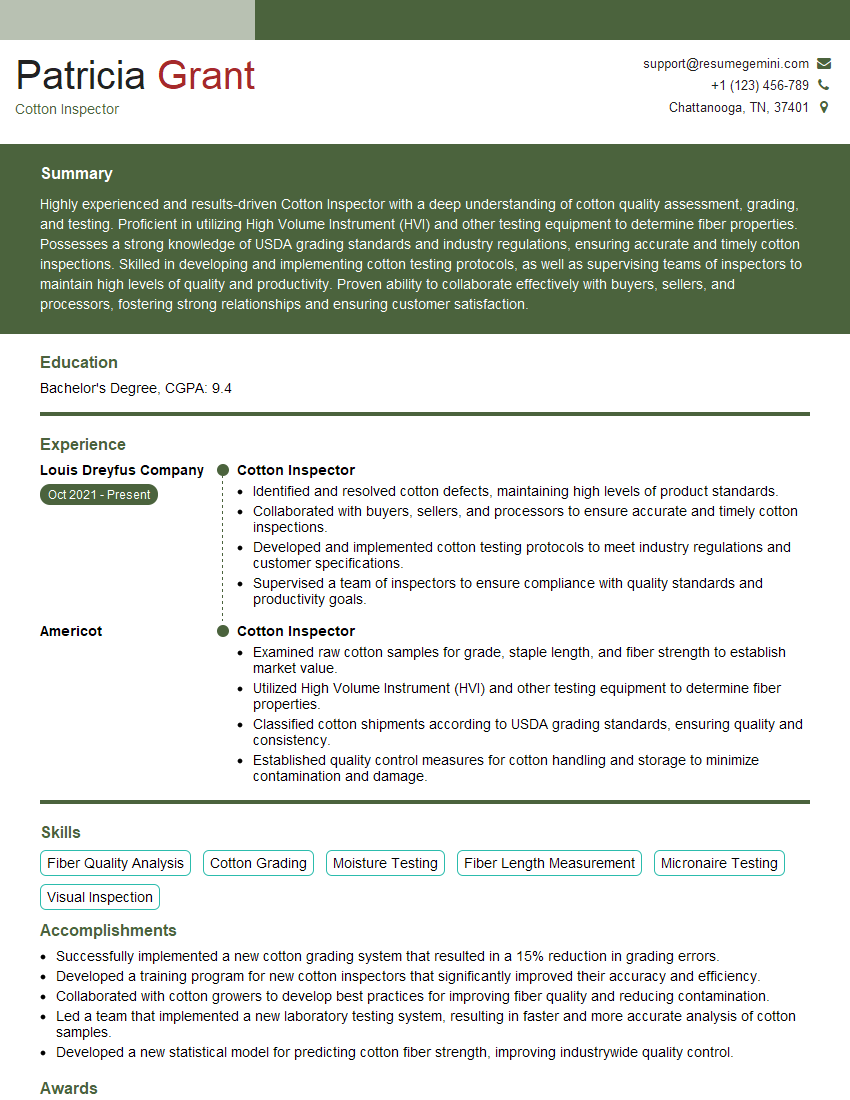

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Inspector

1. What is the process you follow when inspecting a cotton sample?

- Firstly, I visually assess the sample for any obvious defects or variations in color, texture, or fiber length.

- Next, I use a microscope to examine the fibers more closely. This allows me to determine the fineness, strength, and maturity of the cotton.

- Additionally, I conduct laboratory tests to measure the moisture content, color, and other important characteristics of the sample.

- Finally, I compile my findings and generate a report that details the quality and grade of the cotton.

2. What are the key quality factors that you assess when inspecting cotton?

Fiber length

- The length of the fibers is a key determinant of the quality of the cotton.

- Cotton with longer fibers is generally stronger and more durable than cotton with shorter fibers.

Fiber Strength

- The strength of the fibers is another important quality factor.

- Stronger fibers are less likely to break or tear, which makes them ideal for use in high-quality textiles.

Micronaire

- Micronaire is a measure of the fineness of the cotton fibers.

- Finer fibers are generally softer and more comfortable to wear than coarser fibers.

Color

- The color of the cotton is another important factor.

- Cotton that is white or off-white is generally more valuable than cotton that is discolored or stained.

Moisture content

- The moisture content of the cotton is also important.

- Cotton that is too dry can be brittle, while cotton that is too wet can be susceptible to mold and mildew.

3. What are some of the common defects that you look for when inspecting cotton?

- Some of the most common defects that I look for when inspecting cotton include:

- Discoloration or staining

- Holes or tears

- Uneven fiber length

- Weak or brittle fibers

- Excessive moisture content

- Presence of foreign matter, such as dirt, trash, or insects

4. What are the different grades of cotton?

- The different grades of cotton are based on a combination of factors, including fiber length, strength, and color.

- The highest grade of cotton is Extra Long Staple (ELS), which has fibers that are at least 1 3/8 inches in length.

- Other grades of cotton include Long Staple (LS), which has fibers that are at least 1 1/16 inches in length, and Short Staple (SS), which has fibers that are less than 1 1/16 inches in length.

5. What are the different uses of the different grades of cotton?

- The different grades of cotton are used for a variety of purposes.

- ELS cotton is used in high-quality textiles, such as fine linens and luxury garments.

- LS cotton is used in a wide range of products, including clothing, bedding, and towels.

- SS cotton is used in products that require less strength and durability, such as batting and insulation.

6. What is the future of the cotton industry?

- The future of the cotton industry is bright.

- Demand for cotton is expected to continue to grow as the global population increases and living standards improve.

- New technologies are being developed to make cotton production more efficient and sustainable.

- Cotton is a versatile fiber that can be used in a wide range of products, so it is well-positioned to meet the needs of the changing global marketplace.

7. What are the challenges facing the cotton industry?

- The cotton industry is facing a number of challenges, including:

- Increased competition from other fibers, such as polyester and rayon

- Rising production costs due to factors such as labor shortages

- Climate change and other environmental issues that can affect cotton production

8. How can the cotton industry overcome these challenges?

- The cotton industry can overcome these challenges by:

- Continuing to invest in research and development to improve cotton production efficiency and quality

- Developing new markets for cotton products

- Promoting the benefits of cotton to consumers

- Collaborating with other stakeholders in the textile industry

- Adopting more sustainable practices

9. What are your strengths as a Cotton Inspector?

- Some of my strengths as a Cotton Inspector include:

- Strong technical skills and knowledge of cotton grading standards

- Excellent attention to detail and ability to identify defects and variations

- Strong communication and interpersonal skills, which enable me to effectively interact with clients and colleagues

- A commitment to providing accurate and unbiased inspections

10. What are your weaknesses as a Cotton Inspector?

- One area where I could improve is in my knowledge of the latest cotton production and processing technologies.

- Additionally, I am always looking for ways to improve my efficiency and accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cotton Inspector is a professional who is responsible for inspecting and evaluating the quality of cotton. They make sure that the cotton meets the required standards for specific end-uses, and provide unbiased and accurate inspection services to their clients.

1. Inspect and evaluate cotton samples

Cotton Inspectors are responsible for inspecting and evaluating cotton samples to determine their quality. The samples are collected from various sources, such as cotton gins, farms, and warehouses. They examine the samples for various characteristics, such as color, fiber length, strength, and moisture content.

- Visually inspect cotton samples for any visible defects, such as discoloration, contamination, or damage.

- Use specialized equipment, such as microscopes and fiber testing machines, to measure the physical properties of cotton samples, such as fiber length, strength, and fineness.

2. Write inspection reports

Cotton Inspectors write inspection reports that summarize the results of their inspections. These reports are used by clients to make decisions about the quality of the cotton and its suitability for their specific end-uses.

- Prepare detailed inspection reports that document the quality of cotton samples, including their physical characteristics, grade, and value.

- Communicate inspection results clearly and effectively to clients, providing recommendations and guidance on cotton quality and suitability for specific applications.

3. Provide technical assistance to clients

Cotton Inspectors often provide technical assistance to their clients. They can answer questions about cotton quality, storage, and handling. They can also provide advice on how to improve the quality of cotton.

- Provide expert advice and guidance to clients on cotton quality, grading, and best practices for storage and handling.

- Conduct training sessions and workshops to educate clients on cotton inspection techniques and the importance of cotton quality standards.

4. Maintain up-to-date knowledge of cotton industry standards

Cotton Inspectors must maintain up-to-date knowledge of cotton industry standards. These standards are constantly changing, so it is important for them to stay informed about the latest developments.

- Stay up-to-date with the latest industry standards and regulations related to cotton inspection and grading.

- Participate in professional development activities, such as workshops and conferences, to enhance knowledge and skills in cotton inspection.

Interview Tips

Preparing for an interview can be daunting, but it is important to remember that the interviewer wants to get to know you and your skills. By following these tips, you can increase your chances of success.

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position. This will help you to understand the company’s culture and what they are looking for in a candidate. You can find information about the company on their website, social media pages, and Glassdoor.

- Research the company’s website, annual reports, and industry news to gain insights into their business operations, financial performance, and market position.

- Learn about the specific role and its responsibilities, as well as the company’s overall cotton inspection processes and quality standards.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked. It is a good idea to practice your answers to these questions in advance. This will help you to feel more confident and prepared during the interview.

- Prepare for questions related to your experience in cotton inspection, including your knowledge of cotton grading standards and testing procedures.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result) to highlight your skills and accomplishments.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This does not mean that you have to wear a suit, but you should dress in clean, pressed clothes that are appropriate for a business setting.

- Choose attire that is clean, wrinkle-free, and fits you well.

- Consider the company culture and dress code when selecting your outfit.

4. Be on time

Punctuality is important, so make sure that you arrive for your interview on time. If you are running late, call the interviewer to let them know.

- Plan your route in advance and allow extra time for unexpected delays.

- If you do encounter any unforeseen circumstances, contact the interviewer promptly to inform them of your situation.

5. Be yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and let your personality shine through.

- Be genuine and authentic in your responses, showcasing your passion for cotton inspection and your commitment to delivering accurate and reliable results.

- Maintain a positive attitude throughout the interview, demonstrating your enthusiasm for the role and the industry.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cotton Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.