Are you gearing up for an interview for a Cotton Presser position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cotton Presser and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

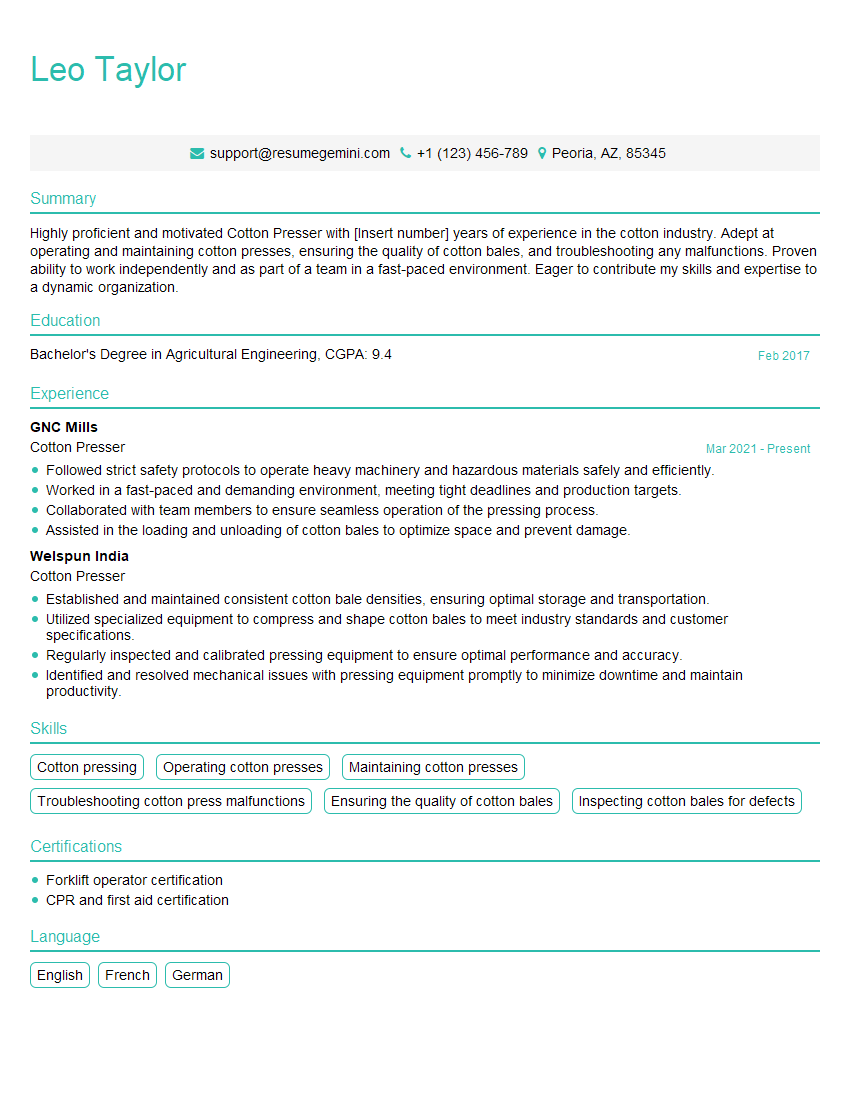

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Presser

1. Describe the process of cotton pressing.

Cotton pressing is a process of compacting raw cotton into bales for easy transportation and storage. Here’s a detailed overview of the process:

- Cotton Harvesting: Raw cotton is harvested from cotton fields using specialized machinery or by hand.

- Ginning: The cotton is then taken to a cotton gin, where it undergoes a ginning process to remove the seeds and other impurities from the cotton fibers.

- Baling: The ginned cotton is fed into a cotton press, which compresses the fibers into rectangular or cylindrical bales.

- Strapping: The bales are secured with metal or plastic straps to maintain their shape and integrity during transportation.

- Weighing and Labeling: Each bale is weighed and labeled with its weight, grade, and other relevant information.

- Storage: The cotton bales are stored in warehouses or on-site storage facilities until they are ready for shipment.

2. What are the different types of cotton presses?

- Hydraulic Press: This type of press uses hydraulic pressure to compress the cotton fibers. Hydraulic presses are known for their high force output and efficiency.

- Mechanical Press: Mechanical presses use a mechanical system, such as gears and levers, to apply force and compress the cotton. They are typically less expensive than hydraulic presses.

- Continuous Press: Continuous presses are designed to handle large volumes of cotton. They operate continuously, feeding cotton into the press from one end and discharging bales from the other end.

3. What are the factors that affect the quality of the pressed cotton bales?

- Quality of Raw Cotton: The quality of the raw cotton used in the pressing process directly impacts the quality of the final bales.

- Moisture Content: The moisture content of the cotton fibers plays a crucial role. Cotton with optimal moisture content presses more effectively and produces higher quality bales.

- Pressing Pressure: The amount of pressure applied during the pressing process affects the density and compactness of the bales.

- Baling Technique: Proper baling techniques ensure that the cotton fibers are evenly distributed and compressed within the bales.

- Storage Conditions: The storage conditions of the bales after pressing, including temperature and humidity, can influence their quality and preservation.

4. What are the common challenges faced in cotton pressing?

- Uneven Bale Density: Ensuring consistent bale density throughout the pressing process is a common challenge.

- Moisture Management: Controlling the moisture content of the cotton fibers is crucial to avoid damage and maintain bale quality.

- Equipment Maintenance: Proper maintenance of cotton presses is essential for optimal performance and safety.

- Safety Hazards: Cotton pressing involves heavy machinery and moving parts, so safety precautions are paramount.

- Fluctuating Cotton Prices: The cotton industry is subject to price fluctuations, which can impact the profitability of cotton pressing operations.

5. What are the latest advancements in cotton pressing technology?

- Automated Control Systems: Automated control systems for cotton presses improve efficiency, reduce labor costs, and enhance bale quality.

- High-Volume Presses: Continuous high-volume presses are capable of handling massive quantities of cotton, increasing productivity and reducing processing time.

- Moisture Monitoring Systems: Advanced moisture monitoring systems ensure accurate measurement and control of cotton moisture content during pressing.

- Smart Baling Techniques: Innovative baling techniques optimize fiber distribution and bale shape using sensors and advanced algorithms.

- Sustainability Initiatives: Cotton pressing technology is increasingly focused on sustainability, such as reducing energy consumption and minimizing waste.

6. What are the safety protocols that must be followed during cotton pressing operations?

- Machine Guarding: All moving parts and potential hazards must be properly guarded to prevent accidents.

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, such as gloves, safety glasses, and hearing protection.

- Lockout/Tagout Procedures: Lockout/tagout procedures ensure that machinery is safely isolated during maintenance or repairs.

- Emergency Stop Buttons: Easily accessible emergency stop buttons must be available throughout the pressing area.

- Training and Supervision: Employees must receive proper training and supervision on safety protocols and procedures.

7. What maintenance tasks are required for cotton presses?

- Regular Inspections: Regular visual inspections of the press, hydraulic systems, and electrical components are crucial.

- Lubrication: Proper lubrication of moving parts extends the life of the equipment and reduces wear and tear.

- Hydraulic System Maintenance: Hydraulic presses require regular monitoring and maintenance of hydraulic fluid levels, filters, and pumps.

- Electrical Maintenance: Electrical components, such as motors, switches, and wiring, need periodic inspections and testing.

- Safety Checks: Safety devices, including emergency stop buttons and guards, must be checked for proper operation.

8. How do you ensure the accuracy of the bale weight and density?

- Calibrated Scales: Use calibrated scales to ensure accurate weighing of the bales.

- Density Measurement Devices: Employ density measurement devices, such as penetrometers, to determine the density and compactness of the bales.

- Regular Calibration: Regularly calibrate both weighing and density measurement equipment to maintain accuracy.

- Monitoring and Adjustments: Monitor the bale weight and density throughout the pressing process and make necessary adjustments to achieve consistency.

- Quality Control Procedures: Implement quality control procedures to verify the accuracy of bale weight and density measurements.

9. What is the importance of bale labeling and how do you ensure its accuracy?

- Identification and Traceability: Bale labeling provides essential information for identification and traceability throughout the supply chain.

- Grade and Quality Indication: The label indicates the grade and quality of the cotton, which is crucial for buyers and end-users.

- Accurate Data: Ensure the accuracy of the data on the bale label, including weight, density, grade, and other relevant information.

- Durable and Weather-Resistant Labels: Use durable and weather-resistant labels that can withstand the storage and transportation conditions.

- Automated Labeling Systems: Consider implementing automated labeling systems to improve efficiency and reduce labeling errors.

10. How do you optimize the efficiency of the cotton pressing process while maintaining bale quality?

- Process Optimization: Analyze the pressing process to identify bottlenecks and areas for improvement.

- Automated Controls: Utilize automated controls to streamline the pressing operation and increase efficiency.

- Equipment Upgrading: Invest in modern and efficient cotton presses to enhance productivity.

- Training and Development: Provide training to operators to improve their skills and optimize the pressing process.

- Quality Control: Implement a robust quality control system to ensure consistent bale quality while optimizing efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Cotton Presser, your primary responsibility will be to operate a cotton press, a machine used to compress cotton into bales for storage and transportation. This involves various tasks that require physical strength, attention to detail, and an understanding of the cotton pressing process.

1. Cotton Loading and Preparation

Before operating the press, you will be responsible for preparing the cotton. This includes:

- Loading raw cotton into the press chamber

- Ensuring that the cotton is evenly distributed and free of debris

- Adjusting the press settings to accommodate the cotton’s weight and density

2. Press Operation

Once the cotton is loaded, you will operate the press to compact it into a dense bale. This involves:

- Activating the press and monitoring its progress

- Adjusting the pressure and timing to achieve the desired bale density

- Releasing the bale once it has been compressed

3. Bale Handling

After the bale has been formed, you will be responsible for handling it. This includes:

- Attaching straps or wires around the bale to secure it

- Moving the bale out of the press and onto a conveyor or storage area

- Ensuring that the bales are stored or shipped properly

4. Machine Maintenance

To ensure the smooth operation of the press, you will be expected to perform basic maintenance tasks. This may include:

- Cleaning and lubricating the press

- Checking for any signs of wear or damage

- Reporting any maintenance issues to a supervisor

Interview Tips

Preparing thoroughly for a Cotton Presser interview can significantly increase your chances of success. Here are some tips to help you ace the interview and land the job:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific Cotton Presser position. This will help you understand the company’s values, goals, and what they are looking for in a candidate.

2. Practice Your Answers

Common interview questions for Cotton Pressers include those related to your experience, skills, and safety procedures. Practice answering these questions clearly and concisely, emphasizing your relevant qualifications and how they align with the job requirements.

3. Highlight Your Physical Strength and Attention to Detail

As a Cotton Presser, physical strength and attention to detail are essential. Be prepared to discuss your physical capabilities and provide examples of how you have demonstrated precision and accuracy in your previous work experience.

4. Emphasize Safety

Safety is paramount in any industrial setting. Showcase your understanding of safety protocols and procedures related to cotton pressing operations. Mention any safety certifications or training programs you have completed.

5. Be Enthusiastic and Eager to Learn

Employers are looking for candidates who are enthusiastic about the role and eager to learn more about the industry. Show your passion for cotton pressing and express your willingness to contribute to the team’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cotton Presser role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.