Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cotton Stripper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

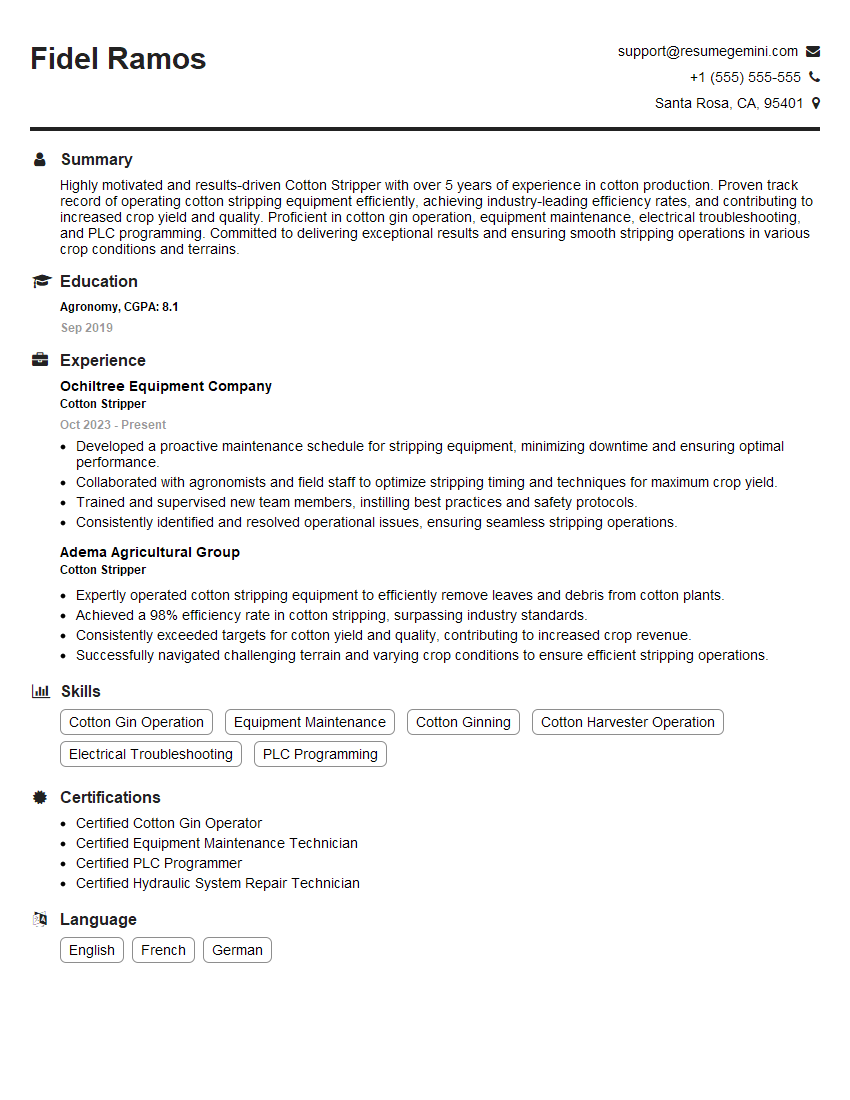

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Stripper

1. Define the role of a Cotton Stripper and its importance in the textile industry?

A Cotton Stripper plays a crucial role in the textile industry by removing the outer layer of cotton fibers, known as linters, from the cottonseed. This process is essential for preparing the cotton fibers for further processing into yarn and fabric. Removing the linters ensures that the fibers are clean, smooth, and free of impurities, resulting in higher-quality textiles.

2. Describe the different types of Cotton Strippers and their respective advantages and disadvantages?

- Saw-type Strippers: Use rotating saws to remove the linters, offering high efficiency and capacity. However, they can damage the fibers if not calibrated properly.

- Roller-type Strippers: Employ rotating rollers to gently remove the linters, minimizing fiber damage but have lower capacity compared to saw-type strippers.

3. Explain the key factors to consider when selecting the appropriate Cotton Stripper for a given application?

- Cotton variety: Different cotton varieties have varying lint qualities, requiring specific stripper configurations.

- Desired fiber quality: The type of stripper influences the fiber quality, affecting the final textile properties.

- Capacity requirements: The stripper’s capacity must match the production volume to maintain efficient operation.

4. Describe the maintenance and calibration procedures required for optimal performance of a Cotton Stripper?

- Regular cleaning: Removing accumulated linters and debris to prevent blockages and ensure smooth operation.

- Blade sharpening/replacement: Sharpening or replacing saw blades or adjusting roller settings to maintain optimal performance.

- Calibration: Verifying and adjusting the stripper’s settings to ensure accurate removal of linters without damaging the fibers.

5. Discuss the safety precautions and industry regulations that must be followed when operating a Cotton Stripper?

- Proper training: Operators must be trained on safe operating procedures to prevent accidents.

- Protective clothing: Gloves, eye protection, and respirators are essential to minimize exposure to dust and debris.

- Guarding: Machine guards and interlocks must be in place to prevent contact with moving parts.

6. Describe the troubleshooting techniques used to diagnose and resolve common problems encountered with Cotton Strippers?

- Low lint removal efficiency: Inspect blades/rollers for wear or damage and ensure proper calibration.

- Excessive fiber damage: Calibrate stripper settings and check for blunt blades/worn rollers.

- Blockages: Clean the machine thoroughly to remove accumulated linters and debris.

7. Discuss the advancements and innovations in Cotton Stripper technology?

- Automated systems: Automated strippers reduce manual labor and improve consistency.

- Fiber quality monitoring: Sensors monitor fiber quality to optimize stripper settings and minimize damage.

- Energy-efficient designs: Strippers with optimized designs reduce energy consumption.

8. Describe the role of a Cotton Stripper operator in a textile manufacturing facility?

A Cotton Stripper operator is responsible for operating, maintaining, and troubleshooting a Cotton Stripper. Their duties include:

- Monitoring the stripper’s performance and making adjustments as needed.

- Performing routine maintenance and calibration tasks.

- Troubleshooting and resolving any operational issues.

- Ensuring safety and compliance with industry regulations.

9. Explain the importance of proper lint removal for cotton fiber quality?

Proper lint removal is crucial for cotton fiber quality because:

- Improved fiber strength: Linters can weaken the fibers, reducing their tensile strength and durability.

- Enhanced spinnability: Clean fibers are easier to spin into yarn, resulting in fewer breakages and higher yarn quality.

- Better fabric properties: Linters can create imperfections in the fabric, affecting its smoothness, appearance, and drape.

10. Describe the environmental considerations associated with Cotton Stripper operation?

- Waste generation: Linters removed by the stripper must be disposed of properly.

- Dust emissions: Stripper operation can generate dust, which must be controlled to minimize environmental impact.

- Energy consumption: Strippers require energy to operate, so energy-efficient designs are preferred.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Stripper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Stripper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cotton Strippers are responsible for operating and maintaining cotton stripping equipment used to remove leaves and debris from cotton plants during harvesting. They play a crucial role in ensuring the quality and yield of the cotton crop.

1. Operating Cotton Stripping Equipment

Operate cotton strippers to remove leaves, stems, and other debris from cotton plants.

- Calibrate and adjust stripper settings to optimize performance and minimize damage to cotton bolls.

- Monitor stripper operations to ensure efficient and effective removal of debris.

2. Maintaining Equipment

Perform routine maintenance and repairs on cotton strippers, including lubrication, cleaning, and minor adjustments.

- Inspect equipment regularly to identify potential problems and take corrective actions.

- Troubleshoot and resolve mechanical or electrical issues to minimize downtime.

3. Monitoring Cotton Quality

Monitor the quality of stripped cotton to ensure it meets established standards.

- Identify and remove any damaged or discolored cotton bolls.

- Maintain records of cotton quality and stripper performance.

4. Safety and Compliance

Follow all safety guidelines and regulations related to the operation of cotton strippers.

- Wear appropriate personal protective equipment (PPE).

- Comply with environmental regulations and guidelines.

Interview Tips

Preparing for an interview can help you increase your chances of success. Here are some tips to help you ace your interview for a Cotton Stripper position:

1. Research the company and position

Visit the company’s website and social media pages to learn about their values, culture, and recent projects. This will help you tailor your answers to show how your skills and experience align with their needs.

- Example: You could mention specific projects or initiatives that demonstrate the company’s commitment to sustainability or innovation.

- Example: You could tailor your resume and cover letter to highlight your experience in operating cotton stripping equipment or your knowledge of cotton quality standards.

2. Practice your answers to common interview questions

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Example: When answering “Tell me about yourself,” focus on highlighting your relevant skills, experience, and qualifications for the Cotton Stripper position.

- Example: For “Why are you interested in this position?,” explain what drew you to the company and the specific role, and how your background makes you a suitable candidate.

3. Highlight your experience and skills

Emphasize your experience in operating cotton stripping equipment, maintaining machinery, and monitoring cotton quality. Also, highlight any relevant certifications or training you have received.

- Example: You could provide specific examples of how you improved the efficiency or quality of cotton stripping operations in previous roles.

- Example: You could mention any certifications or training in cotton stripping equipment maintenance or cotton quality control.

4. Show your passion for the cotton industry

Express your interest and enthusiasm for the cotton industry. Explain why you are passionate about producing high-quality cotton and contributing to the success of the industry.

- Example: You could share your knowledge of current trends and challenges in the cotton industry and how you stay updated on best practices.

- Example: You could mention any involvement or interest in cotton industry organizations or events.

5. Prepare questions to ask the interviewer

Ask thoughtful questions at the end of the interview to show your interest and engagement. This can also help you gain valuable insights into the company and the position.

- Example: You could ask about the company’s growth plans, the specific challenges or opportunities faced by the cotton stripping team, or the opportunities for professional development.

- Example: Asking about the company’s commitment to sustainability or the use of advanced technologies in cotton stripping operations demonstrates your interest in these areas.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cotton Stripper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cotton Stripper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.