Are you gearing up for an interview for a Cottrell Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cottrell Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

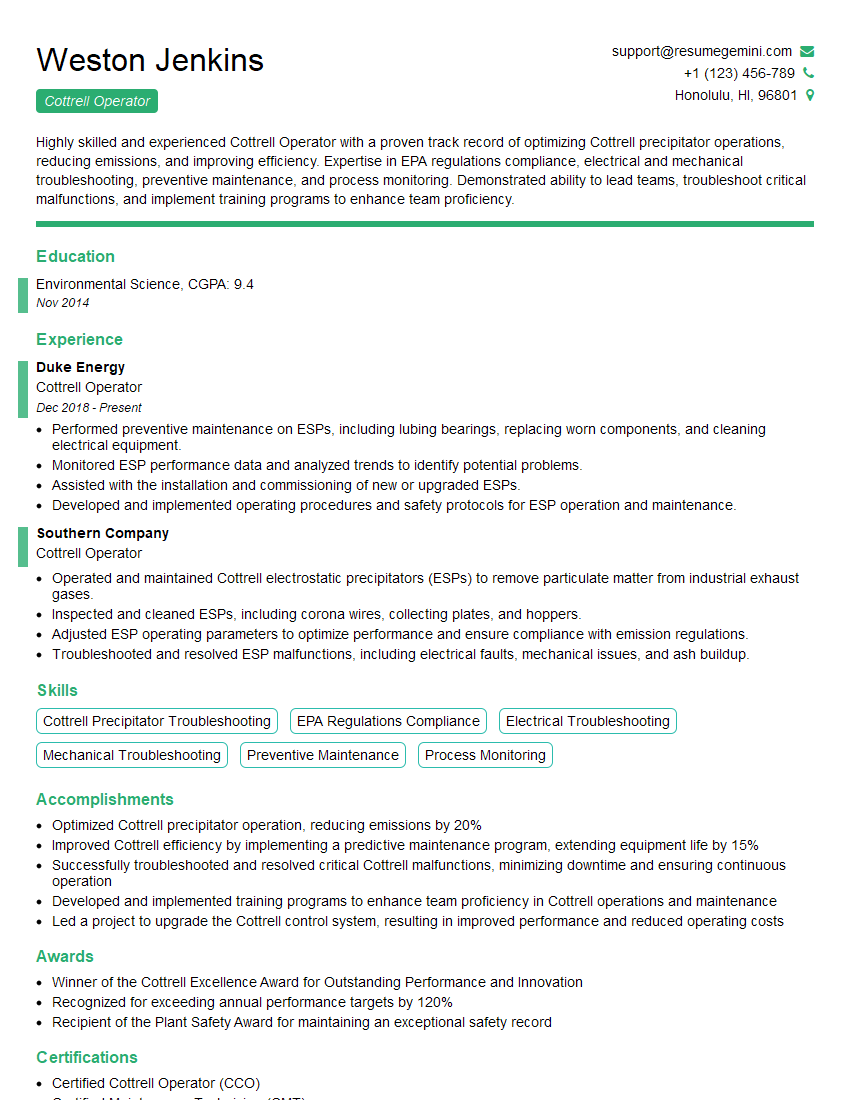

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cottrell Operator

1. Explain the working principle of a Cottrell precipitator?

A Cottrell precipitator works on the principle of electrostatic precipitation. It removes particulate matter from a gas stream by applying a high voltage to a series of electrodes. The electrodes create an electric field that charges the particles in the gas stream. The charged particles are then attracted to oppositely charged collection plates, where they stick and are removed from the gas stream.

2. What are the different types of Cottrell precipitators?

Wet type

- Uses a liquid to collect particles

- More efficient than dry type

- Higher maintenance costs

Dry type

- Uses dry plates to collect particles

- Less efficient than wet type

- Lower maintenance costs

3. What are the factors that affect the efficiency of a Cottrell precipitator?

The efficiency of a Cottrell precipitator is affected by several factors, including:

- Voltage: Higher voltage results in higher efficiency.

- Plate spacing: Smaller plate spacing results in higher efficiency.

- Gas velocity: Higher gas velocity results in lower efficiency.

- Particle size: Smaller particles are more difficult to collect than larger particles.

- Particle charge: Particles with a higher charge are more easily collected.

4. What are the advantages of using a Cottrell precipitator?

Cottrell precipitators offer several advantages, including:

- High efficiency: Cottrell precipitators can remove up to 99% of particulate matter from a gas stream.

- Low maintenance: Cottrell precipitators require relatively little maintenance.

- Long lifespan: Cottrell precipitators can last for decades with proper maintenance.

5. What are the applications of Cottrell precipitators?

Cottrell precipitators are used in a wide variety of applications, including:

- Power plants: Cottrell precipitators are used to remove particulate matter from the flue gas of power plants.

- Industrial facilities: Cottrell precipitators are used to remove particulate matter from the exhaust gas of industrial facilities, such as steel mills and cement plants.

- Waste incineration facilities: Cottrell precipitators are used to remove particulate matter from the exhaust gas of waste incineration facilities.

6. What are the challenges associated with operating a Cottrell precipitator?

Operating a Cottrell precipitator can be challenging due to several factors, including:

- Electrical hazards: The high voltage used in Cottrell precipitators can create electrical hazards.

- Mechanical hazards: The moving parts of Cottrell precipitators can create mechanical hazards.

- Chemical hazards: The particulate matter collected by Cottrell precipitators can contain hazardous chemicals.

7. What are the safety precautions that must be taken when operating a Cottrell precipitator?

Several safety precautions must be taken when operating a Cottrell precipitator, including:

- Electrical safety: Wear appropriate PPE, such as rubber gloves and insulated boots. Do not touch any electrical components.

- Mechanical safety: Be aware of moving parts and keep clear of them.

- Chemical safety: Wear appropriate PPE, such as a respirator, when handling collected particulate matter.

8. What are the maintenance procedures that must be performed on a Cottrell precipitator?

Cottrell precipitators require regular maintenance to ensure optimal performance. Some of the maintenance procedures that must be performed include:

- Cleaning the plates: The plates must be cleaned regularly to remove accumulated particulate matter.

- Inspecting the electrodes: The electrodes must be inspected regularly for damage.

- Testing the voltage: The voltage must be tested regularly to ensure that it is within the proper range.

9. What are the troubleshooting procedures that can be performed on a Cottrell precipitator?

If a Cottrell precipitator is not operating properly, several troubleshooting procedures can be performed to identify and fix the problem. Some of the troubleshooting procedures that can be performed include:

- Checking the power supply: Make sure that the Cottrell precipitator is receiving power.

- Inspecting the plates: Look for any damage or buildup on the plates.

- Testing the voltage: Make sure that the voltage is within the proper range.

- Inspecting the electrodes: Look for any damage or corrosion on the electrodes.

10. What are the future trends in Cottrell precipitator technology?

The future of Cottrell precipitator technology is expected to see several trends, including:

- Increased use of advanced materials: New materials are being developed that can withstand the harsh conditions inside a Cottrell precipitator.

- Improved design: New designs are being developed to improve the efficiency and performance of Cottrell precipitators.

- Increased automation: Cottrell precipitators are becoming increasingly automated, which reduces the need for human intervention.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cottrell Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cottrell Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cottrell Operators perform a wide range of duties in power plants, including:

1. Operating and maintaining Cottrell precipitators

Cottrell precipitators are devices that remove particulate matter from exhaust gases. Cottrell Operators are responsible for ensuring that these devices are operating properly and efficiently.

- Monitoring the operation of Cottrell precipitators

- Adjusting the settings of Cottrell precipitators to optimize performance

- Troubleshooting and repairing Cottrell precipitators

2. Performing inspections and maintenance

Cottrell Operators perform regular inspections of Cottrell precipitators and other equipment in the power plant. They also perform maintenance tasks, such as cleaning and lubricating equipment.

- Inspecting Cottrell precipitators for wear and tear

- Cleaning and lubricating Cottrell precipitators

- Performing minor repairs on Cottrell precipitators

3. Monitoring emissions

Cottrell Operators monitor the emissions from the power plant to ensure that they are within regulatory limits. They also collect and analyze data on emissions.

- Collecting and analyzing data on emissions

- Reporting emissions data to regulatory agencies

- Implementing measures to reduce emissions

4. Supervising other employees

Cottrell Operators may supervise other employees, such as helpers or technicians. They are responsible for training, motivating, and evaluating these employees.

- Training and motivating other employees

- Evaluating the performance of other employees

- Disciplining other employees

Interview Tips

Here are some tips to help you ace your interview for a Cottrell Operator position:

1. Research the company and the position

Take some time to learn about the company you are applying to and the specific position you are interviewing for. This will help you answer questions intelligently and demonstrate your interest in the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company, if possible

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Think about your experiences and skills

- Prepare specific examples to support your answers

- Practice your answers out loud

3. Dress professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Choose a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call the interviewer to let them know.

- Give yourself plenty of time to get to the interview

- If you are running late, call the interviewer to let them know

- Do not arrive more than 15 minutes early

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cottrell Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!