Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Counter Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

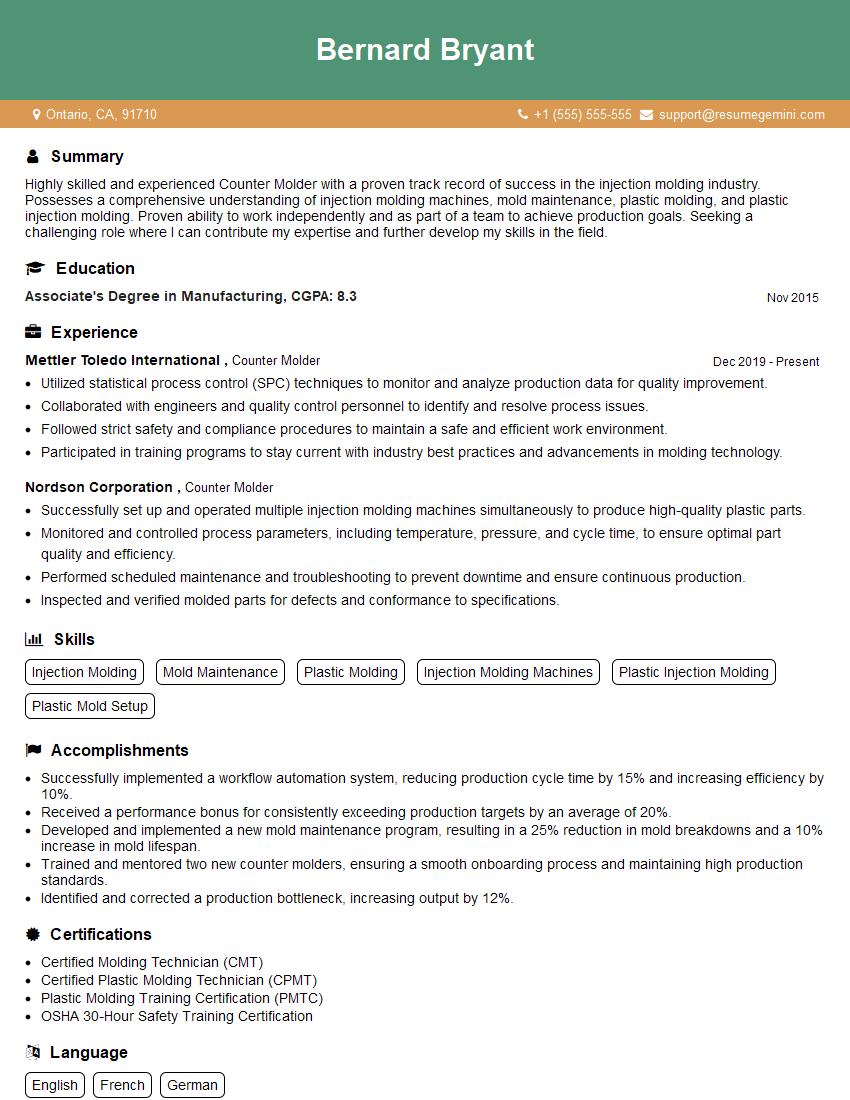

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Counter Molder

1. What are the key responsibilities of a Counter Molder?

The key responsibilities of a Counter Molder include:

- Operate counter molding machines to produce molded plastic parts.

- Set up and adjust machines to meet production requirements.

- Monitor machine operation and make adjustments as needed.

- Inspect finished parts for quality and accuracy.

- Maintain a clean and organized work area.

2. What is the difference between counter molding and compression molding?

Counter molding is a molding process that uses a female mold (counter die) to shape a plastic material. The material is forced into the mold by a male die (plunger). Compression molding, on the other hand, uses two male molds to compress the material into shape.

3. What are the advantages and disadvantages of counter molding?

Advantages of counter molding include:

- High production rates

- Good dimensional accuracy

- Low tooling costs

Disadvantages of counter molding include:

- Limited part geometry

- Potential for flash

- High maintenance costs

4. What are the different types of plastic materials used in counter molding?

The most common types of plastic materials used in counter molding include:

- Polystyrene (PS)

- Polyethylene (PE)

- Polypropylene (PP)

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate (PC)

5. What are the safety precautions that must be taken when operating a counter molding machine?

Safety precautions that must be taken when operating a counter molding machine include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Keeping hands and other body parts away from moving machine parts

- Never reaching into a mold while it is in operation

- Following all manufacturer’s instructions for safe operation

6. How do you troubleshoot a counter molding machine that is not producing parts to specification?

To troubleshoot a counter molding machine that is not producing parts to specification, I would first check the following:

- The machine settings to make sure they are correct

- The mold to make sure it is clean and free of any debris

- The material to make sure it is the correct type and grade

- The process to make sure it is being followed correctly

If the problem cannot be resolved by checking these items, I would then contact a qualified technician for assistance.

7. What is the most important thing to consider when selecting a counter molding machine?

The most important thing to consider when selecting a counter molding machine is the type of parts that will be produced.

- The machine should be able to produce the parts to the required dimensions, tolerances, and quality standards.

- The machine should also be able to meet the production requirements in terms of cycle time and output.

8. What are the different types of counter molding molds?

The different types of counter molding molds include:

- Single-cavity molds: These molds have one cavity that produces one part at a time.

- Multi-cavity molds: These molds have multiple cavities that produce multiple parts at a time.

- Family molds: These molds produce a variety of different parts from the same mold.

- Insert molds: These molds are used to insert metal or other inserts into plastic parts.

9. What are the different types of counter molding processes?

The different types of counter molding processes include:

- Compression molding: This process uses a plunger to force the material into the mold cavity.

- Transfer molding: This process uses a transfer pot to inject the material into the mold cavity.

- Injection molding: This process uses an injection screw to inject the material into the mold cavity.

10. What are the quality control procedures that are used in counter molding?

The quality control procedures that are used in counter molding include:

- Visual inspection of parts

- Dimensional measurement of parts

- Testing of parts for strength and durability

- Statistical process control

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Counter Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Counter Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Counter Molders play a crucial role in the production process, responsible for operating counter molding machines to create molds and patterns for a variety of products. Their primary duties include:

1. Machine Operation

• Effectively set up, operate, and maintain counter molding machines

• Adhering to established operating procedures and safety regulations

• Monitoring machine performance and ensuring optimal production

• Performing routine maintenance and troubleshooting to prevent downtime

2. Mold Fabrication

• Skilled in creating molds and patterns using counter molding techniques

• Working with various materials, such as plastic, metal, and composite

• Interpreting blueprints and technical drawings to ensure accuracy

• Operating hand tools and power equipment to shape and finish molds

3. Quality Control

• Performing thorough inspections of finished molds to ensure they meet specifications

• Identifying and correcting any defects or imperfections

• Maintaining documentation related to mold production and quality

• Collaborating with design engineers to improve mold quality

4. Production Efficiency

• Optimizing production processes to increase efficiency and reduce waste

• Working effectively as part of a team to achieve production targets

• Suggesting improvements to streamline operations and reduce cycle times

• Keeping the work area clean and organized to maintain productivity

Interview Tips

Preparing for an interview as a Counter Molder requires thorough research and a solid understanding of the role. Here are some tips to help you ace the interview:

1. Research the Company and Position

• Familiarize yourself with the company’s products, services, and industry

• Thoroughly review the job description and identify the key responsibilities

• Highlight your skills and experience that align with the position’s requirements

• Prepare examples that demonstrate your proficiency in operating counter molding machines and fabricating molds

2. Emphasize Your Technical Skills

• Demonstrate a deep understanding of counter molding processes and techniques

• Highlight your experience in working with different materials and equipment

• Quantify your accomplishments whenever possible, such as reducing cycle times or improving mold quality

• Present yourself as a skilled and knowledgeable professional

3. Showcase Your Attention to Detail

• Emphasize your strong attention to detail and meticulous approach to work

• Explain how you ensure accuracy and precision in mold fabrication and quality control

• Provide examples of how you have identified and corrected defects in molds

• Highlight your commitment to delivering high-quality products

4. Highlight Your Problem-Solving Abilities

• Demonstrate your ability to troubleshoot and resolve issues efficiently

• Share experiences where you have successfully identified and resolved problems with counter molding machines or mold production

• Emphasize your logical thinking and analytical skills

• Present yourself as a proactive and resourceful problem-solver

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Counter Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.