Feeling lost in a sea of interview questions? Landed that dream interview for Coverstitch Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coverstitch Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

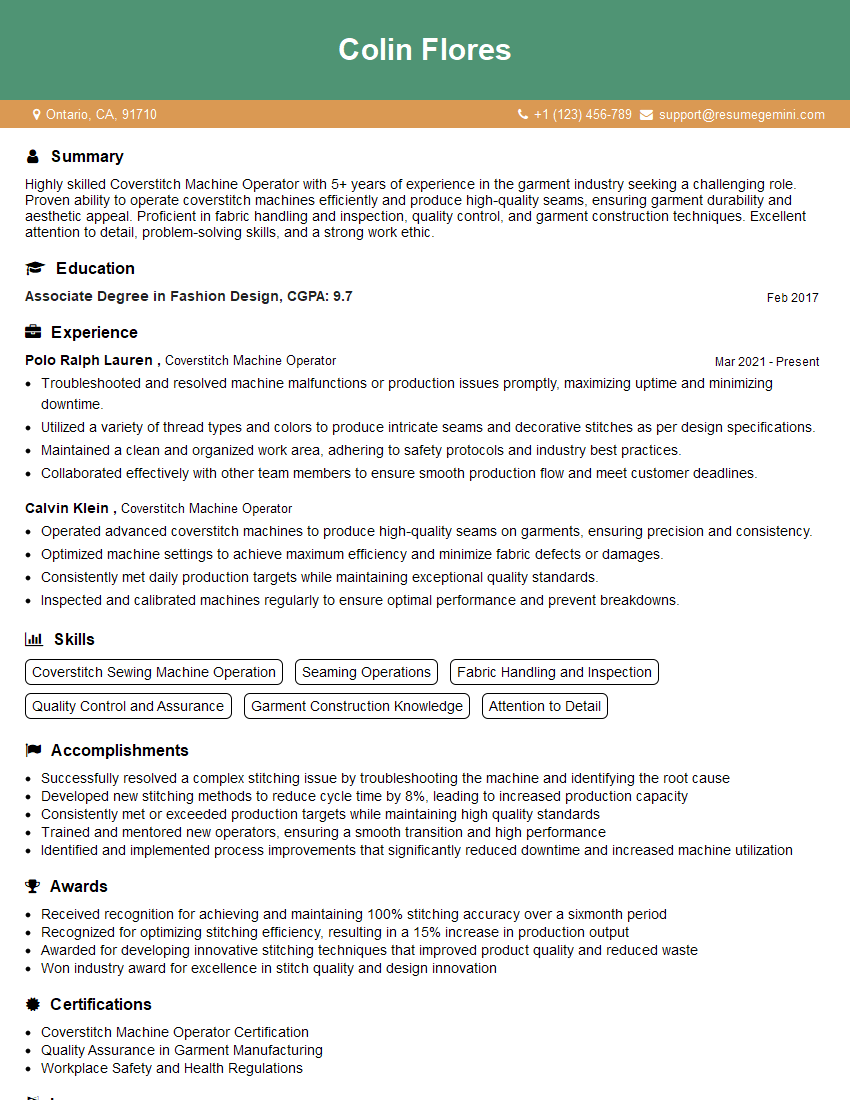

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coverstitch Machine Operator

1. Describe the different types of coverstitch machines you have worked on?

In my previous roles, I have operated various types of coverstitch machines, including:

- Flatbed Coverstitch Machine: Designed for sewing flat surfaces and can be used for attaching elastic, binding, and hemming.

- Cylinder-Bed Coverstitch Machine: Suitable for sewing cylindrical and tubular garments like T-shirts, leggings, and swimwear.

- Overlock with Coverstitch Capability: Offers both overlocking and coverstitching functions, allowing for a combination of seam finishing and coverstitching.

2. How do you troubleshoot common problems with coverstitch machines?

Stitching Quality Issues

- Skipped Stitches: Check for proper needle size, thread tension, and timing.

- Puckered or Loose Stitches: Adjust thread tension, ensure correct stitch length and width, and check for lint buildup.

Machine Issues

- Malfunctioning Feeders: Clean and adjust feeders to ensure smooth fabric flow.

- Tension Problems: Inspect and adjust thread tension throughout the machine.

3. What type of thread do you typically use for coverstitch machines?

For coverstitch machines, I prefer to use high-quality polyester or nylon thread for both the looper and needle threads. These threads provide:

- Durability: Resists abrasion and breakage, ensuring strong and long-lasting seams.

- Stretch: Allows for flexibility in sewn garments, especially for knits and elastics.

- Uniformity: Consistent thread size and texture prevent thread breakage and promote smooth stitching.

4. How do you maintain the needle and looper system of a coverstitch machine?

- Needle: Inspect the needle regularly for damage and replace it when necessary. Lubricate the needle regularly to reduce friction and prevent breakage.

- Looper: Clean the looper using a lint brush or compressed air. Check for any nicks or burrs and smooth them out using a fine abrasive.

- Timing: Ensure proper timing between the needle and looper to achieve accurate stitch formation.

5. Describe the safety protocols you follow while operating coverstitch machines?

- Protective Gear: Wear safety glasses and protective clothing to minimize the risk of injury.

- Machine Inspection: Check the machine thoroughly before each use, including cords, plugs, and moving parts.

- Keep Hands Away: Never touch moving parts while the machine is operating.

- Maintenance: Schedule regular maintenance to ensure the machine is in optimal condition.

6. How do you ensure high-quality coverstitch output in production?

- Proper Setup: Calibrate the machine according to fabric type and seam specifications.

- Quality Check: Regularly inspect seams for stitch quality, tension, and overall appearance.

- Maintenance: Adhere to a regular maintenance schedule to maintain machine performance.

- Training: Train operators thoroughly on proper machine operation and quality control techniques.

7. How do you handle fabric shrinkage when working with coverstitch machines?

To mitigate fabric shrinkage, I employ the following techniques:

- Preshrink Fabric: Prewash or preshrink the fabric before sewing to prevent shrinkage after coverstitching.

- Use Steam: Apply steam while sewing to reduce shrinkage and improve stitch quality.

- Test Stitches: Conduct test stitches on a scrap piece of fabric to determine the optimal stitch length and tension for the specific fabric.

8. What are the different stitch types used on coverstitch machines?

Common coverstitch stitch types include:

- Single Needle Coverstitch: Creates a single row of stitches on the right side of the fabric, providing a clean and secure finish.

- Double Needle Coverstitch: Uses two needles to create parallel rows of stitches, resulting in a more decorative and durable seam.

- Triple Needle Coverstitch: Employs three needles to produce a wider and more intricate coverstitch.

- Chain Coverstitch: Creates a chain-like stitch on the right side of the fabric, offering stretch and durability for activewear and swimwear.

9. How do you adjust the stitch length and tension on a coverstitch machine?

- Stitch Length: Adjust the stitch length knob or dial to achieve the desired length between stitches.

- Thread Tension: Adjust the tension dials for both the looper and needle threads to ensure balanced tension and prevent puckering or skipped stitches.

10. What are your strengths and weaknesses as a coverstitch machine operator?

Strengths

- Technical Proficiency: Skilled in operating and troubleshooting coverstitch machines.

- Attention to Detail: Meticulous in ensuring high-quality stitching and consistent output.

- Production Efficiency: Capable of maintaining high productivity levels while adhering to quality standards.

Weaknesses

- Limited Experience: May need additional experience with specialized coverstitch techniques or fabrics.

- Speed vs. Quality:Balancing speed and quality can sometimes be challenging, but I am committed to achieving both.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coverstitch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coverstitch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coverstitch Machine Operator is responsible for operating coverstitch machines to sew garments. They must be able to read and follow sewing instructions, and have a strong attention to detail. Key job responsibilities include:

1. Sewing Garments

Use coverstitch machines to sew together different pieces of fabric to create garments. Ensure that the seams are strong and durable, and that the stitches are even and consistent.

2. Inspecting Garments

Inspect finished garments for any defects, such as skipped stitches or uneven seams. Mark any defects and repair them as needed.

3. Maintaining Machines

Keep coverstitch machines clean and in good working order. Perform regular maintenance tasks, such as oiling and adjusting the machine.

4. Troubleshooting Problems

Troubleshoot and resolve any problems that arise with the coverstitch machines. This may involve identifying the source of the problem, making repairs, or replacing parts.

Interview Tips

To ace your interview for a Coverstitch Machine Operator position, you should be prepared to discuss your skills and experience. Here are some tips to help you prepare:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their culture and values, and will give you a better idea of the type of work you’ll be doing.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice answering these questions in advance so that you can do so confidently and clearly.

3. Be Prepared to Discuss Your Skills and Experience

The interviewer will be interested in your skills and experience as a Coverstitch Machine Operator. Be sure to highlight your ability to sew garments, inspect garments, maintain machines, and troubleshoot problems. You can also mention any relevant certifications or training that you have.

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This doesn’t mean you need to wear a suit, but you should choose clothing that is clean, pressed, and appropriate for the workplace.

5. Be on Time

Punctuality is important, so be sure to arrive for your interview on time. This shows the interviewer that you’re respectful of their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coverstitch Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!