Are you gearing up for a career in Cracking Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cracking Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

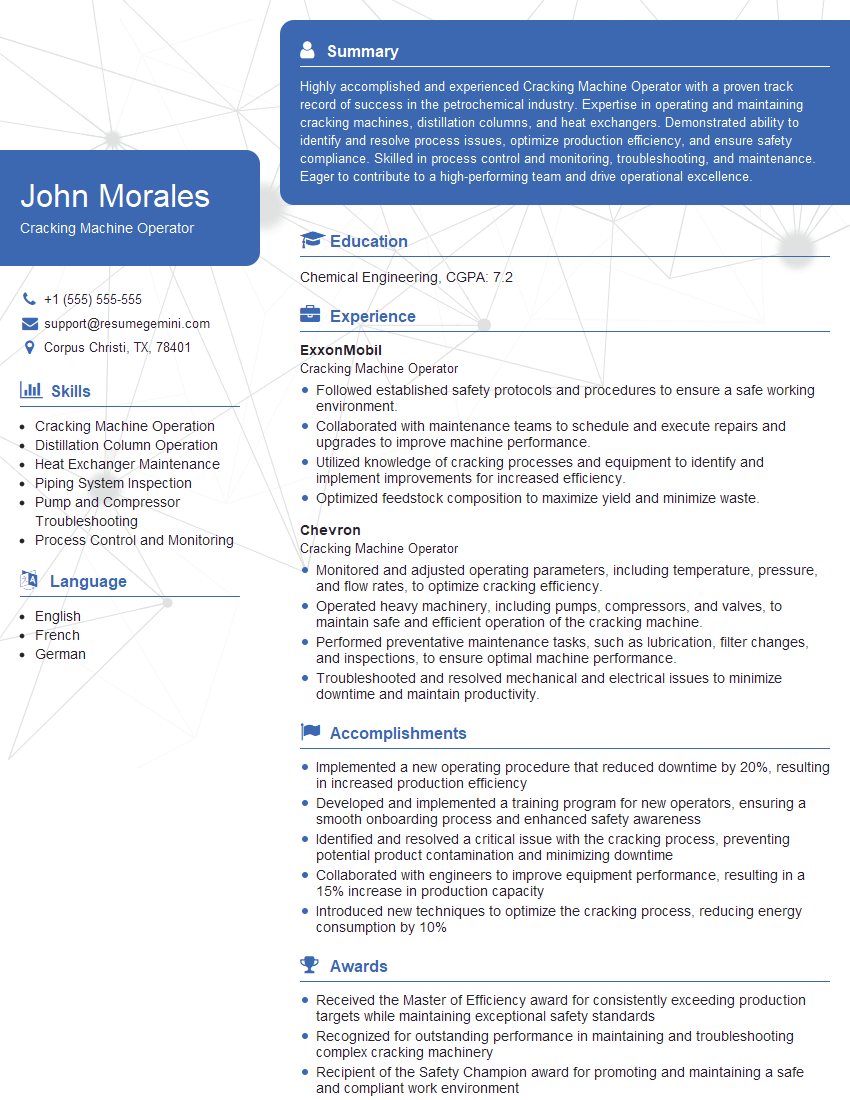

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cracking Machine Operator

1. Describe the main responsibilities of a Cracking Machine Operator?

- Monitoring and controlling the operation of cracking machines to ensure efficient and safe production of hydrocarbons.

- Adjusting machine settings, such as temperature, pressure, and feed rates, to optimize yields and product quality.

- Performing regular maintenance and troubleshooting to keep machines in optimal condition.

- Monitoring alarms and gauges to identify potential problems and take corrective actions.

- Working in a team environment to achieve production targets and maintain a safe work environment.

2. Explain the process of cracking in a Cracking Machine?

Cracking Process

- Cracking is a process of breaking down larger hydrocarbon molecules into smaller ones to produce fuels and other valuable products.

- In a Cracking Machine, hydrocarbons are heated and exposed to a catalyst, causing them to break apart and rearrange.

Types of Cracking

- Thermal cracking: using high temperatures only.

- Catalytic cracking: using a catalyst (e.g., zeolites) to increase efficiency and product selectivity.

- Hydrocracking: using hydrogen to reduce coke formation and improve product quality.

3. How do you handle and mitigate common issues that occur during the cracking process?

- Coke formation: Regularly cleaning and maintaining the reactor, adjusting process parameters, and using additives to reduce coke buildup.

- Product contamination: Monitoring equipment, maintaining proper feed quality, and conducting regular inspections to prevent contamination.

- Process upsets: Quickly identifying and responding to alarms, following established emergency procedures, and working with engineers to address underlying issues.

- Equipment malfunctions: Troubleshooting and repairing equipment, conducting preventive maintenance, and replacing worn or damaged parts promptly.

- Safety concerns: Adhering to safety regulations, wearing appropriate protective gear, and following established safety protocols to minimize risks.

4. Describe the safety protocols and emergency procedures you are familiar with in a Cracking Machine Operation?

- Wearing appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, and safety glasses.

- Following lock-out/tag-out procedures when performing maintenance or repairs.

- Knowing the location of emergency shutdown buttons and fire extinguishers.

- Responding to alarms promptly and following established emergency evacuation plans.

- Participating in regular safety training and drills to maintain awareness and proficiency.

5. Explain the importance of maintaining accurate records and logs in Cracking Machine Operation?

- Tracking operating parameters, such as temperatures, pressures, and feed rates, to ensure consistent product quality and efficiency.

- Documenting maintenance activities and repairs to facilitate preventative maintenance and troubleshoot issues.

- Recording production data to monitor yields and identify areas for improvement.

- Providing data for regulatory compliance and reporting purposes.

- Facilitating communication and knowledge sharing among operators and maintenance personnel.

6. How do you prioritize and manage multiple tasks in a fast-paced Cracking Machine Operation environment?

- Setting clear priorities based on safety, production goals, and maintenance needs.

- Delegating tasks to team members when appropriate.

- Communicating effectively with supervisors and other operators to coordinate activities.

- Using checklists and other tools to stay organized and track progress.

- Remaining calm and focused under pressure, maintaining situational awareness.

7. Describe a situation where you identified and resolved a problem in Cracking Machine Operation?

In my previous role as a Cracking Machine Operator, I encountered a drop in product yield and quality. Through troubleshooting, I identified a faulty temperature sensor that was providing inaccurate readings. I replaced the sensor, recalibrated the system, and closely monitored the process until stable operation was restored. This resulted in increased yields and improved product specifications.

8. How do you stay updated with the latest industry advancements and best practices in Cracking Machine Operation?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Seeking training opportunities from equipment manufacturers and industry experts.

- Staying informed about new regulations and industry standards.

9. How do you ensure the quality of the final product in Cracking Machine Operation?

- Monitoring key parameters such as temperature, pressure, and feed rates.

- Performing regular product sampling and testing.

- Maintaining clean equipment and following proper operating procedures.

- Calibrating instruments regularly to ensure accuracy.

- Working closely with laboratory personnel to analyze results and identify areas for improvement.

10. How would you handle a situation where production targets are not being met in Cracking Machine Operation?

- Reviewing operating parameters and identifying potential bottlenecks.

- Analyzing product quality data to identify any issues that may be impacting yields.

- Consulting with supervisors and engineers to explore solutions and implement improvements.

- Optimizing equipment performance through adjustments and maintenance.

- Working with the team to enhance coordination and efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cracking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cracking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cracking Machine Operators are responsible for operating and maintaining cracking machines, which are used to break down larger molecules into smaller ones. This process is essential for the production of gasoline, diesel fuel, and other petroleum products.

1. Operating Cracking Machines

Cracking Machine Operators are responsible for starting, stopping, and monitoring cracking machines. They must also make sure that the machines are operating properly and that the products are meeting specifications.

- Starting, stopping, and monitoring cracking machines

- Ensuring that the machines are operating properly

- Making sure that the products are meeting specifications

2. Maintaining Cracking Machines

Cracking Machine Operators are also responsible for maintaining cracking machines. This includes cleaning, lubricating, and inspecting the machines. They must also make sure that the machines are in good working order and that they are safe to operate.

- Cleaning, lubricating, and inspecting cracking machines

- Ensuring that the machines are in good working order

- Making sure that the machines are safe to operate

3. Troubleshooting Problems

Cracking Machine Operators must be able to troubleshoot problems with cracking machines. This includes identifying the problem, finding the cause of the problem, and fixing the problem.

- Identifying problems with cracking machines

- Finding the cause of the problem

- Fixing the problem

4. Quality Control

Cracking Machine Operators are also responsible for quality control. This includes testing the products to make sure that they meet specifications. They must also make sure that the products are safe for use.

- Testing the products to make sure that they meet specifications

- Ensuring that the products are safe for use

Interview Tips

Cracking Machine Operator interviews can be tough, but there are a few things you can do to prepare and increase your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position. This will help you understand the company’s culture and what they are looking for in a Cracking Machine Operator. It will also help you answer questions about the company and the position during your interview.

- Visit the company’s website

- Read about the company in the news

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked in a Cracking Machine Operator interview. These questions may include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with cracking machines?

It is important to practice answering these questions so that you can deliver your answers confidently and clearly during your interview.

3. Be prepared to talk about your experience

In your interview, you will likely be asked to talk about your experience with cracking machines. Be prepared to discuss your skills and knowledge in detail. You should also be prepared to talk about any specific projects or accomplishments that you have related to cracking machines.

- Highlight your skills and knowledge in cracking machines

- Discuss specific projects or accomplishments that you have related to cracking machines

4. Be professional and enthusiastic

Cracking Machine Operator interviews can be stressful, but it is important to stay professional and enthusiastic throughout the process. This will show the interviewer that you are serious about the position and that you are confident in your abilities.

- Dress professionally

- Be on time for your interview

- Be polite and respectful to the interviewer

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cracking Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!