Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cracking Still Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

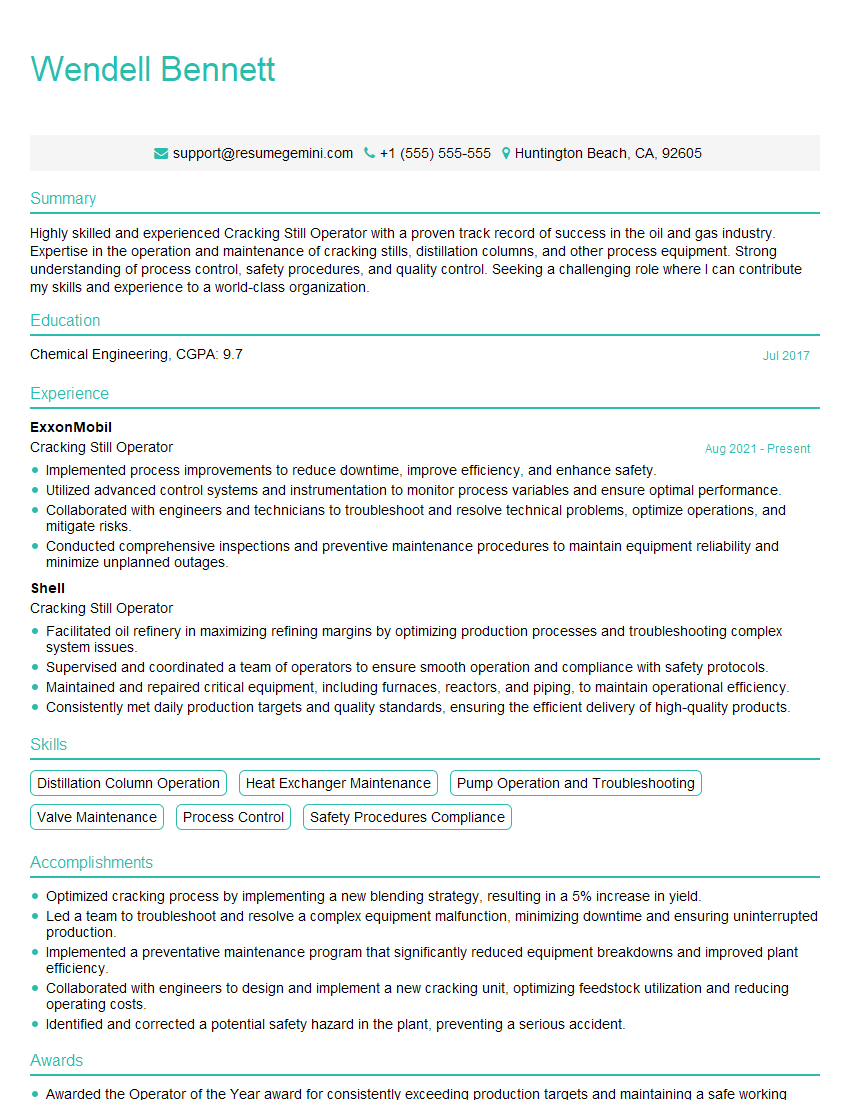

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cracking Still Operator

1. What are the main responsibilities of a Cracking Still Operator?

As a highly skilled Cracking Still Operator, my primary responsibilities include:

- Operating and monitoring a cracking still unit, ensuring optimal cracking efficiency.

- Controlling process variables such as temperature, pressure, and feed rates to maximize yield and product quality.

2. Describe the different types of crude oils and their impact on the cracking process.

Composition and Properties:

- Light crudes (e.g., paraffinic) are easier to crack, producing higher yields of lighter products (gasoline, diesel).

- Heavy crudes (e.g., asphaltic) contain more impurities and require more severe cracking conditions, resulting in higher yields of heavier products (coke, fuel oil).

Impact on Cracking:

- The composition of the crude oil influences the severity of the cracking conditions required.

- Heavy crudes require higher temperatures and longer residence times to achieve desired conversions.

3. What are the potential hazards associated with cracking still operations, and how do you mitigate them?

Cracking still operations involve several hazards, including:

- High temperatures and pressures: Proper equipment design, maintenance, and safety procedures are crucial to prevent explosions.

- Toxic chemicals: Exposure to gases like hydrogen sulfide and carbon monoxide is minimized through ventilation and respiratory protection.

- Flammable materials: Strict adherence to safe handling protocols and fire prevention measures is essential.

4. Explain the role of catalysts in the cracking process.

Catalysts play a vital role in the cracking process by:

- Increasing reaction rates: Catalysts reduce the activation energy required for cracking reactions, accelerating the conversion of heavier molecules.

- Improving selectivity: Zeolite-based catalysts selectively promote desired cracking pathways, maximizing the yield of specific products.

5. Describe the equipment and instruments used in a cracking still unit.

- Cracking furnace: Heats the feedstock to initiate cracking reactions.

- Fractionating column: Separates the cracked products based on their boiling points.

- Analyzer: Monitors and controls process variables, including temperature, pressure, and feed composition.

- Control system: Automates the operation and ensures process stability.

6. How do you optimize the yield and quality of products in a cracking still unit?

Optimizing product yield and quality involves:

- Feedstock selection: Selecting crudes with appropriate properties for the desired product slate.

- Controlling process variables: Adjusting temperature, pressure, and residence time to maximize target product yields while minimizing unwanted reactions.

- Catalyst management: Regularly monitoring catalyst activity and replacing it as needed to maintain optimal cracking efficiency.

7. What are the different types of troubleshooting techniques used in cracking still operations?

- Process monitoring: Continuously monitoring process variables and identifying deviations from optimal conditions.

- Equipment inspection: Regular inspection of equipment for leaks, corrosion, and other potential issues.

- Data analysis: Analyzing historical data and trends to identify potential problems and implement corrective actions.

8. How do you handle unexpected events or emergencies in a cracking still unit?

In emergency situations, I follow established protocols:

- Safety first: Ensure the safety of personnel and the environment.

- Equipment shutdown: Initiate a safe and orderly shutdown of the unit.

- Root cause analysis: Investigate the cause of the emergency and implement measures to prevent recurrence.

9. What are the key performance indicators (KPIs) for a Cracking Still Operator and how do you measure them?

- Product yield: Quantity and quality of desired products (e.g., gasoline, diesel).

- Product quality: Meeting specifications for properties such as octane number and sulfur content.

- Unit efficiency: Energy consumption and overall production rates.

- Safety record: Absence of incidents and accidents.

10. How do you stay up-to-date with the latest advancements in cracking still technology?

To stay informed, I engage in continuous learning through:

- Technical conferences and workshops: Attending industry events to learn about new developments and best practices.

- Trade publications and journals: Subscribing to relevant publications to stay abreast of research and technological advancements.

- Collaboration with peers: Exchanging knowledge and experiences with other Cracking Still Operators through professional networks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cracking Still Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cracking Still Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cracking Still Operators are responsible for operating and maintaining cracking stills, which are used to convert crude oil into gasoline, diesel fuel, and other products. Their key responsibilities include:

1. Monitoring and controlling the cracking still

Cracking Still Operators monitor and control the cracking still to ensure that it is operating safely and efficiently. They adjust the temperature, pressure, and flow rate of the crude oil to optimize the cracking process.

- Monitor and adjust the temperature, pressure, and flow rate of the crude oil.

- Control the flow of crude oil through the still.

- Monitor the quality of the finished product.

2. Maintaining the cracking still

Cracking Still Operators perform routine maintenance on the cracking still to keep it in good working condition. They inspect the still for leaks, cracks, and other damage. They also clean and lubricate the still’s components.

- Inspect the still for leaks, cracks, and other damage.

- Clean and lubricate the still’s components.

- Replace worn or damaged parts.

3. Troubleshooting and repairing the cracking still

Cracking Still Operators troubleshoot and repair the cracking still when it breaks down. They identify the problem and make the necessary repairs to get the still back up and running as soon as possible.

- Identify and troubleshoot the problem.

- Make the necessary repairs.

- Test the still to ensure that it is operating properly.

4. Following safety procedures

Cracking Still Operators follow all safety procedures to protect themselves and others from injury. They wear protective clothing and equipment, and they follow all lockout/tagout procedures.

- Wear protective clothing and equipment.

- Follow lockout/tagout procedures.

- Follow all safety procedures.

Interview Tips

To prepare for an interview for a Cracking Still Operator position, you should:

1. Research the company and the position

Learn as much as you can about the company and the position you are applying for. This will help you answer the interviewer’s questions intelligently and show that you are interested in the job.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work in the industry.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in a clear and concise manner.

- Prepare your answers to common interview questions.

- Practice your answers with a friend or family member.

- Time yourself to make sure your answers are concise.

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you are applying for. For example, if you have experience operating and maintaining cracking stills, be sure to mention this in your interview.

- Highlight your skills and experience in your resume.

- Discuss your skills and experience in your interview.

- Provide examples of your work experience.

4. Dress professionally and arrive on time

First impressions matter, so be sure to dress professionally for your interview. Also, arrive on time for your interview. This will show the interviewer that you are respectful of their time.

- Dress professionally for your interview.

- Arrive on time for your interview.

- Be polite and respectful to the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cracking Still Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.