Are you gearing up for an interview for a Cracking Unit Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cracking Unit Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

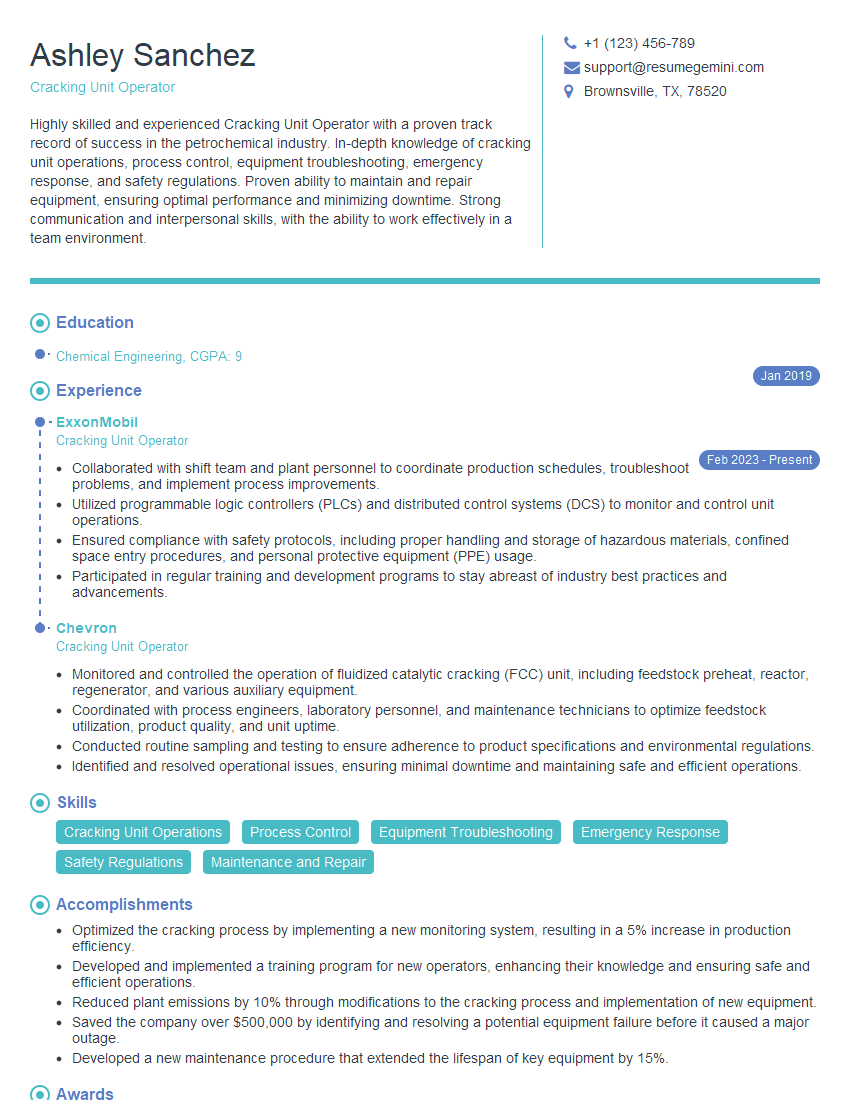

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cracking Unit Operator

1. Explain the role of a cracking unit in an oil refinery?

A cracking unit is a vital part of an oil refinery and plays a crucial role in converting heavy and less valuable fractions of crude oil into lighter and more valuable products. It breaks down long-chain hydrocarbon molecules into smaller and more useful ones through thermal or catalytic processes. This process, known as cracking, helps increase the yield of gasoline, diesel, and other products that are essential for various industries and consumers.

2. Describe the types of cracking processes and their advantages and disadvantages?

Thermal Cracking

- Advantages: Simple process, low investment cost.

- Disadvantages: Produces a high yield of gas and low-octane gasoline.

Catalytic Cracking

- Advantages: Produces high-octane gasoline and less gas.

- Disadvantages: More complex process, higher investment cost.

Hydrocracking

- Advantages: Produces high-quality fuels and minimizes coke formation.

- Disadvantages: Requires high pressure and temperature, complex process.

3. What are the key parameters to monitor and control during the cracking process, and why?

- Temperature: High temperatures promote cracking reactions, but excessive temperatures can lead to coke formation and product degradation.

- Pressure: Pressure affects the conversion rate and selectivity of the cracking reactions.

- Feedstock composition: Different feedstocks require different cracking conditions to achieve optimal results.

- Catalyst activity: Catalysts play a crucial role in catalytic cracking, and their activity needs to be monitored to ensure efficient operation.

4. How do you address common operational issues in a cracking unit, such as coking and fouling?

- Coking: Regular decoking procedures, using steam or air, to remove coke deposits from the reactor and catalyst.

- Fouling: Regular cleaning and maintenance of heat exchangers and other equipment to prevent fouling and ensure optimal heat transfer.

- Adjusting process parameters: Optimizing temperature, pressure, and feedstock composition to minimize coking and fouling.

5. Explain the safety precautions and emergency procedures for working in a cracking unit?

- Adhering to proper PPE and safety protocols.

- Being aware of hazardous materials and potential risks.

- Knowing the emergency shutdown procedures and evacuation routes.

- Regular safety training and drills to ensure preparedness.

6. How do you optimize the performance of a cracking unit to maximize product yield?

- Selecting the appropriate cracking process and feedstock.

- Optimizing process parameters (temperature, pressure, etc.).

- Maintaining catalyst activity and regenerating it as needed.

- Regular monitoring and troubleshooting to identify and address performance issues.

7. What are the latest advancements in cracking technology, and how do they impact the industry?

- Improved catalysts for increased efficiency and product selectivity

- Advanced process control systems for better optimization

- New technologies for producing cleaner fuels and reducing emissions

8. Explain the role of computer-based control systems in monitoring and operating a cracking unit?

- Automated monitoring and control of process parameters.

- Data acquisition and analysis for performance optimization.

- Improved safety and reliability through alarm systems and interlocks.

9. Describe the different types of maintenance procedures carried out in a cracking unit, and their importance?

Preventive Maintenance

- Regular inspections, cleaning, and lubrication to prevent failures.

Predictive Maintenance

- Using sensors and data analysis to predict potential issues.

Corrective Maintenance

- Repairing or replacing equipment after a failure.

10. How do you stay up-to-date with the latest developments and best practices in the field of cracking technology?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in professional organizations and networking with peers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cracking Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cracking Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cracking Unit Operators are responsible for the safe and efficient operation of cracking units, which convert crude oil into gasoline, diesel fuel, and other products. Their key responsibilities include:

1. Monitoring and controlling process variables

Cracking Unit Operators monitor and control a variety of process variables, including temperature, pressure, and flow rates, to ensure that the cracking process is operating within safe and efficient limits.

- Using control panels and computer systems to adjust process variables

- Responding to alarms and taking corrective action to prevent or mitigate process upsets

2. Troubleshooting and repairing equipment

Cracking Unit Operators troubleshoot and repair equipment problems, such as leaks, blockages, and equipment failures, to maintain the smooth operation of the cracking unit.

- Identifying equipment problems and taking corrective action

- Using hand tools and power tools to repair equipment

3. Maintaining safety and environmental standards

Cracking Unit Operators maintain safety and environmental standards by following established procedures, wearing appropriate personal protective equipment, and monitoring for potential hazards.

- Following established safety and environmental procedures

- Wearing appropriate personal protective equipment

- Monitoring for potential hazards and taking corrective action

4. Communicating with other operators and supervisors

Cracking Unit Operators communicate with other operators and supervisors to coordinate work activities, exchange information, and resolve issues.

- Communicating with other operators and supervisors to coordinate work activities

- Exchanging information and resolving issues

Interview Tips

Cracking Unit Operator interviews can be challenging, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

Take some time to research the company you’re interviewing with and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job. It will also show the interviewer that you’re interested in the position and that you’ve taken the time to learn more about the company.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions

- Highlight your skills and experience that are relevant to the position

- Be concise and to the point

3. Be prepared to talk about your safety experience

Safety is a top priority in the oil and gas industry, so you’re likely to be asked about your safety experience during your interview. Be prepared to discuss your knowledge of safety regulations, your experience with safety procedures, and your commitment to safety.

- Describe your experience with safety regulations and procedures

- Explain how you would handle a safety situation

- Show the interviewer that you’re committed to safety

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, as being late will reflect poorly on you.

- Wear a suit or business casual attire

- Be punctual

- Make eye contact and handshake firmly

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cracking Unit Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!