Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Creel Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

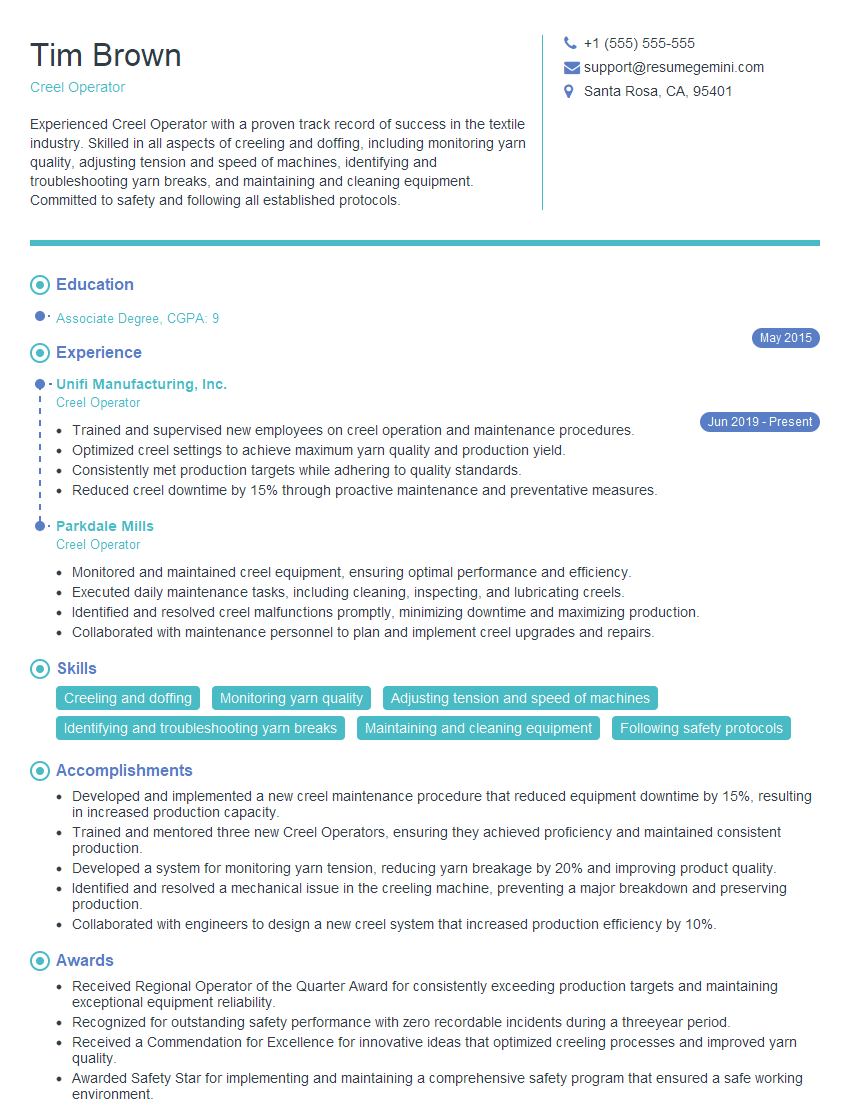

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Creel Operator

1. What are the key responsibilities of a Creel Operator?

The key responsibilities of a Creel Operator include:

- Loading and unloading creels from spinning machines

- Monitoring the creels and ensuring that the yarn is running smoothly

- Identifying and correcting any problems with the creels or the yarn

- Maintaining a clean and organized work area

2. What are the different types of creels used in spinning?

Types of Creels

- Uptwister Creel

- Cone Creel

- Bottle Bobbin Creel

- Universal Creel

- Draw Frame Creel

3. What are the factors that can affect the quality of the yarn produced?

The factors that can affect the quality of the yarn produced include:

- The quality of the raw materials

- The condition of the spinning machines

- The skill of the Creel Operator

- The environmental conditions

4. How do you ensure that the creels are loaded and unloaded properly?

To ensure that the creels are loaded and unloaded properly, I follow these steps:

- Inspect the creels for any damage

- Load the creels with the correct type and amount of yarn

- Secure the yarn on the creels

- Unload the creels when they are full

- Inspect the yarn for any damage

5. What do you do if you identify a problem with a creel or the yarn?

If I identify a problem with a creel or the yarn, I take the following steps:

- Stop the machine

- Identify the problem

- Correct the problem

- Restart the machine

- Monitor the machine to ensure that the problem has been resolved

6. How do you maintain a clean and organized work area?

To maintain a clean and organized work area, I follow these steps:

- Clean the creels and the surrounding area regularly

- Inspect the creels and the yarn for any damage

- Dispose of any waste materials properly

- Follow all safety procedures

7. What are the safety hazards associated with working as a Creel Operator?

The safety hazards associated with working as a Creel Operator include:

- Moving machinery

- Electrical hazards

- Chemical hazards

- Repetitive motions

- Slips, trips, and falls

8. How do you stay up-to-date on the latest creeling techniques?

To stay up-to-date on the latest creeling techniques, I do the following:

- Attend industry training programs

- Read industry publications

- Network with other Creel Operators

- Experiment with different creeling techniques

9. What is your experience with creeling different types of yarn?

I have experience creeling a variety of different types of yarn, including:

- Cotton yarn

- Polyester yarn

- Nylon yarn

- Wool yarn

- Acrylic yarn

10. What is your experience with different types of creeling machines?

I have experience with a variety of different types of creeling machines, including:

- Automatic creeling machines

- Semi-automatic creeling machines

- Manual creeling machines

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Creel Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Creel Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Creel Operator plays a crucial role in the textile industry, overseeing the operation, maintenance, and repair of creels, which are large frames that hold yarn bobbins in textile manufacturing.

1. Creel Operation and Monitoring

The primary responsibility of a Creel Operator is to ensure the smooth operation of creels by performing the following tasks:

- Loading and unloading creels with yarn bobbins

- Adjusting and aligning yarn tension and feed rate

- Monitoring creel performance and identifying any issues or defects

- Maintaining a clean and organized work area around the creels

2. Creel Maintenance and Repair

To ensure optimal creel performance, Creel Operators are responsible for regular maintenance and repair tasks, including:

- Inspecting creels for wear and tear, damage, or misalignment

- Cleaning and lubricating creel components to minimize friction and ensure smooth operation

- Performing minor repairs, such as replacing worn or damaged parts

- Reporting major issues or defects to supervisors for further action

3. Quality Control

Creel Operators are responsible for ensuring the quality of yarn produced by the creels:

- Inspecting yarn for defects, such as knots, unevenness, or contamination

- Taking corrective actions to address yarn quality issues

- Maintaining records of yarn quality and production

4. Safety and Compliance

Creel Operators must prioritize safety in the workplace by following established safety protocols:

- Wearing appropriate personal protective equipment (PPE)

- Operating creels according to safety guidelines

- Reporting any safety hazards or concerns to supervisors

- Maintaining a clean and organized work area to minimize risks

Interview Tips

To ace an interview for a Creel Operator position, candidates should prepare thoroughly and showcase their relevant skills and experience.

1. Research the Company and Role

Research the company’s background, industry, and specific products or services to demonstrate your interest and knowledge of the organization.

- Review the job description carefully to understand the key responsibilities and qualifications required for the role.

- Research the company’s website, social media, and industry news to gain insights into their culture, values, and current projects.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills and experience in operating and maintaining creels, as well as your understanding of yarn quality control.

- Provide specific examples of your past work experience, showcasing your ability to identify and resolve creel issues efficiently.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work on production and quality.

3. Demonstrate Problem-Solving Abilities

Creel Operators are expected to troubleshoot and resolve issues promptly. Highlight your problem-solving skills through real-life examples.

- Describe a situation where you encountered a creel malfunction and the steps you took to diagnose and fix the problem.

- Explain how you prioritize competing demands and manage your time effectively, especially during production deadlines.

4. Emphasize Safety and Quality Consciousness

Stress your commitment to workplace safety and quality standards.

- Explain your understanding of safety protocols and your experience in following them consistently.

- Provide examples of how you ensure yarn quality and maintain high production standards in your previous roles.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the role and the company.

- Prepare questions about the company’s future plans, training opportunities, or specific projects related to creel operation.

- Inquire about the company’s commitment to employee development and safety initiatives.

Next Step:

Now that you’re armed with the knowledge of Creel Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Creel Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini