Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Creosoting Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

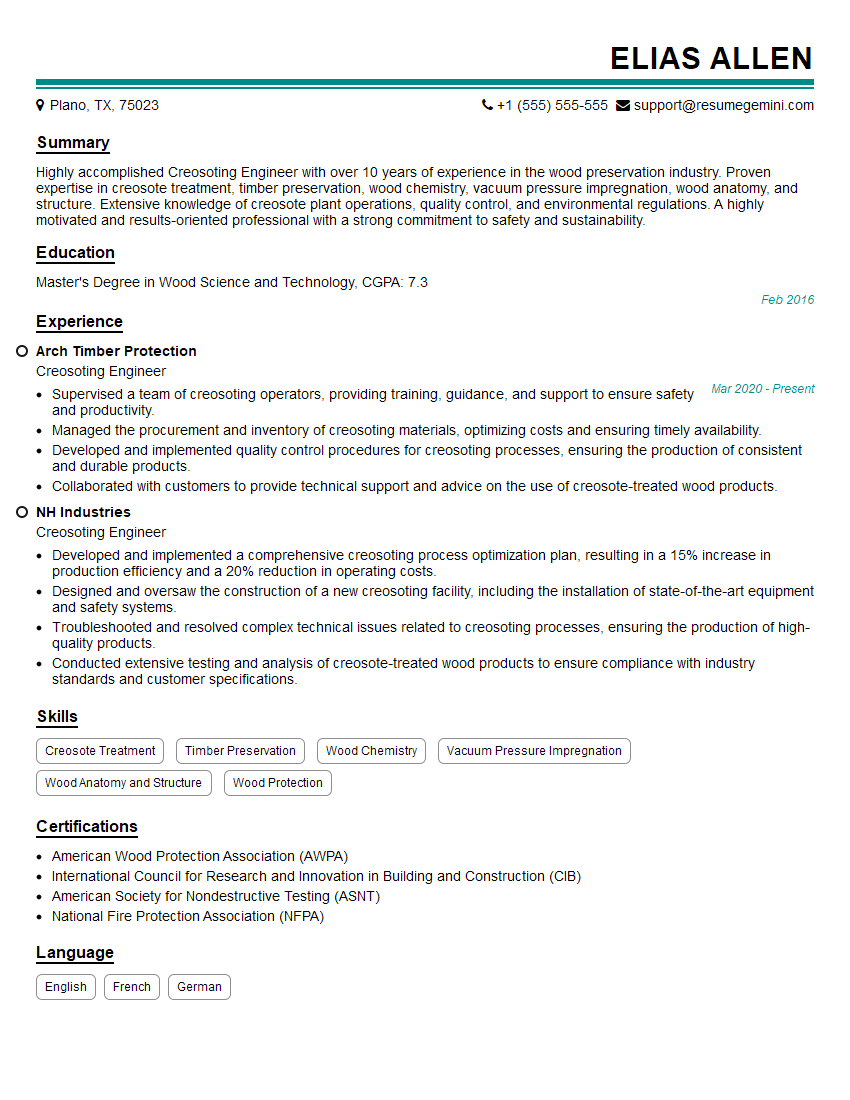

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Creosoting Engineer

1. What are the key factors to consider when designing a creosoting plant?

When designing a creosoting plant, the following key factors should be considered:

- The type of wood to be treated

- The desired level of protection

- The available budget

- The environmental regulations

- The safety requirements

2. What are the different types of creosote used in the industry?

Coal tar creosote

- The most common type of creosote used in the industry

- Derived from the distillation of coal tar

- Has a dark brown to black color

- Contains a high concentration of polycyclic aromatic hydrocarbons (PAHs)

Waterborne creosote

- A newer type of creosote that is more environmentally friendly

- Made from a mixture of creosote oil and water

- Has a lighter color than coal tar creosote

- Contains a lower concentration of PAHs

3. What are the advantages and disadvantages of using creosote as a wood preservative?

Advantages:

- Creosote is a very effective wood preservative

- It can protect wood from rot, decay, and insects

- It is relatively inexpensive

Disadvantages:

- Creosote is a hazardous material

- It can cause skin irritation, respiratory problems, and cancer

- It can contaminate soil and water

4. What are the key safety precautions that must be taken when working with creosote?

When working with creosote, the following key safety precautions must be taken:

- Wear protective clothing, including gloves, a respirator, and goggles

- Avoid contact with skin and eyes

- Do not breathe in creosote fumes

- Work in a well-ventilated area

- Dispose of creosote-contaminated materials properly

5. What are the environmental regulations that apply to creosoting plants?

Creosoting plants are subject to a number of environmental regulations, including:

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

- The Toxic Substances Control Act

6. What are the different methods of applying creosote to wood?

Creosote can be applied to wood using a variety of methods, including:

- Brushing

- Spraying

- Dipping

- Pressure treatment

7. What are the quality control procedures that must be followed when creosoting wood?

The following quality control procedures must be followed when creosoting wood:

- The wood must be inspected for defects

- The creosote must be tested to ensure that it meets the required specifications

- The application of creosote must be monitored to ensure that it is applied evenly and to the correct depth

- The treated wood must be inspected to ensure that it meets the required quality standards

8. What are the common problems that can occur when creosoting wood?

The following common problems can occur when creosoting wood:

- The wood may not be properly treated

- The creosote may not be applied evenly

- The treated wood may not meet the required quality standards

- The creosote may contaminate the environment

9. What are the future trends in the creosoting industry?

The following are some of the future trends in the creosoting industry:

- The use of more environmentally friendly creosotes

- The development of new application methods

- The increased use of creosoting for marine applications

- The growth of the creosoting industry in developing countries

10. What are your qualifications for this position?

I have a bachelor’s degree in chemical engineering from the University of California, Berkeley. I have also worked as a process engineer for a creosoting plant for the past five years. In this role, I was responsible for the design, operation, and maintenance of the plant’s creosoting process. I am also a member of the American Wood Protection Association.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Creosoting Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Creosoting Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Creosoting Engineers are responsible for the preservation and treatment of wood products to enhance their durability and resistance to decay and pests. Their primary duties include:

1. Creosoting Process Supervision

Oversee the creosoting process, ensuring that wood products are treated according to specified standards and regulations.

- Monitor treatment parameters such as temperature, pressure, and solution concentration.

- Conduct quality control inspections to assess the effectiveness of the creosoting process.

2. Wood Product Inspection

Inspect wood products before and after treatment to evaluate their condition, identify defects, and ensure adherence to quality standards.

- Identify and classify wood species, grades, and sizes.

- Examine wood for signs of damage, decay, or insect infestation.

3. Treatment Plan Development

Develop and implement treatment plans based on the intended use and exposure conditions of wood products.

- Determine appropriate creosote grade and treatment method.

- Calculate treatment specifications, including pressure, temperature, and duration.

4. Equipment Maintenance and Calibration

Maintain and calibrate creosoting equipment, including retorts, pressure vessels, and pumps.

- Perform regular inspections and repairs to ensure safe and efficient operation.

- Calibrate equipment to maintain accurate measurements and treatment parameters.

Interview Tips

To ace an interview for a Creosoting Engineer position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and values. Research the specific job responsibilities and the industry’s current trends.

- Visit the company’s website, read industry publications, and connect with employees on LinkedIn.

- Prepare questions to ask the interviewer that demonstrate your knowledge and interest.

2. Highlight Your Technical Expertise

Showcase your technical skills and knowledge in creosoting processes, wood preservation, and quality control. Provide specific examples of your experience and accomplishments.

- Discuss your proficiency in creosote treatment methods, including pressure treatment and vacuum impregnation.

- Demonstrate your understanding of wood anatomy, decay mechanisms, and pest control.

3. Emphasize Your Problem-Solving Skills

Creosoting Engineers often encounter challenges related to equipment malfunctions, treatment issues, or wood quality. Highlight your ability to solve problems effectively and efficiently.

- Describe a situation where you identified a problem and developed a solution that improved the creosoting process.

- Explain your approach to troubleshooting and your ability to think critically.

4. Prepare for Industry-Specific Questions

Be prepared to discuss industry-specific topics, such as the latest advancements in wood preservation technologies, environmental regulations, and sustainability practices.

- Read industry publications and attend conferences to stay updated on current trends.

- Discuss how you incorporate sustainability into your work and your understanding of industry best practices.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Creosoting Engineer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.