Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Creping Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

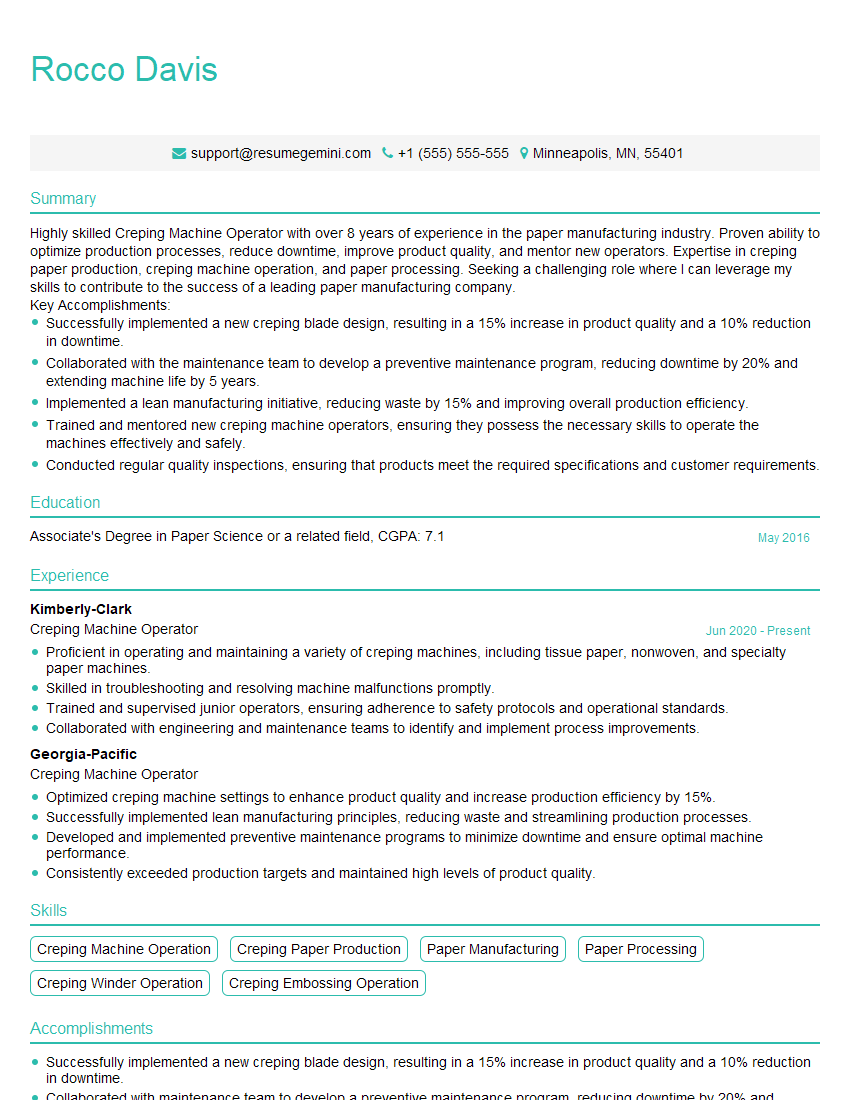

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Creping Machine Operator

1. Explain the key operational principles of a creping machine.

The creping process on a creping machine involves passing tissue paper through a heated Yankee cylinder, which has a creped surface. The tissue paper adheres to the cylinder, and when it is pulled away, it forms the characteristic crepe texture due to the differential drying rates between the surface and interior of the paper.

- Maintaining optimal temperature and pressure on the Yankee cylinder

- Controlling the speed and tension of the tissue paper as it passes through the machine

- Adjusting the doctor blade to achieve the desired crepe depth

- Monitoring the moisture content of the paper to ensure proper creping

2. Describe the different types of crepe finishes and how they are achieved.

Embossed Crepe

- Created by passing the paper through rollers with embossed patterns

- Results in a decorative, three-dimensional texture

Crinkled Crepe

- Formed by mechanically crimping the paper

- Produces a soft, pliable texture

Mechanically Creped

- Utilized to create high-absorbency crepe paper

- Involves passing the paper through a series of blades to create a highly textured surface

3. How do you ensure the quality of the creped paper produced by the machine?

Quality control is crucial in ensuring the production of high-quality creped paper. I employ a comprehensive approach to quality management, including:

- Regular monitoring of machine parameters, such as temperature, pressure, and speed

- Visual inspection of the paper for defects, such as wrinkles, tears, or uneven creping

- Laboratory testing of the paper to assess its properties, such as tensile strength, absorbency, and softness

- Continuous process improvement through analysis of production data and feedback from customers

4. What are the common maintenance tasks required for a creping machine?

To maintain optimal performance and longevity of the creping machine, I regularly perform the following maintenance tasks:

- Cleaning and lubrication of all moving parts

- Inspection and replacement of worn or damaged components, such as bearings, seals, and doctor blades

- Calibration and adjustment of machine settings to ensure accuracy and efficiency

- Regular cleaning and maintenance of the Yankee cylinder to prevent buildup and ensure proper creping

5. Describe the safety protocols you follow when operating a creping machine.

Safety is paramount when operating a creping machine. I strictly adhere to the following safety protocols:

- Wearing appropriate personal protective equipment, including gloves, safety glasses, and earplugs

- Maintaining a clean and organized work area

- Following proper lockout/tagout procedures before performing any maintenance or repairs

- Being aware of potential hazards, such as rotating machinery, hot surfaces, and sharp objects

- Reporting any accidents or near-misses promptly

6. How do you troubleshoot common problems that may arise during creping operations?

During creping operations, I have encountered and resolved various common problems. My troubleshooting approach involves:

- Identifying the problem and its potential causes

- Consulting technical manuals and documentation

- Inspecting the machine for any visible issues

- Performing diagnostic tests and measurements

- Adjusting machine settings or replacing components as needed

- Documenting the problem and the steps taken to resolve it for future reference

7. What are the environmental considerations related to creping machine operations?

Creping machine operations can have environmental implications, which I am mindful of and address responsibly. Key considerations include:

- Minimizing waste and optimizing resource usage

- Proper disposal of wastewater and chemicals

- Reducing energy consumption through efficient machine operation and maintenance

- Complying with environmental regulations and industry best practices

8. How do you stay updated on the latest advancements in creping technology?

To stay abreast of the latest advancements in creping technology, I engage in continuous learning and professional development. My strategies include:

- Attending industry conferences and webinars

- Reading technical journals and articles

- Consulting with experts and vendors

- Participating in training programs offered by equipment manufacturers

9. Describe a challenging creping project you worked on and how you overcame the obstacles.

In a previous role, I encountered a challenging creping project involving the production of a highly absorbent and durable tissue paper. The initial trials resulted in low absorbency and frequent machine breakdowns. Through thorough analysis and experimentation, I identified the following obstacles:

- Incorrect creping blade angle

- Suboptimal Yankee cylinder temperature

- Insufficient pulp refining

To overcome these obstacles, I implemented the following measures:

- Adjusted the creping blade angle to optimize crepe depth

- Fine-tuned the Yankee cylinder temperature to enhance drying efficiency

- Increased the pulp refining time to improve fiber bonding

These adjustments resulted in significant improvements in absorbency and machine performance, ultimately leading to the successful completion of the project.

10. What qualities and skills make you an ideal candidate for this Creping Machine Operator position?

My technical expertise in creping operations, combined with my strong troubleshooting and problem-solving abilities, make me an ideal candidate for this position. Additionally, I possess the following qualities and skills:

- Excellent communication and interpersonal skills

- Ability to work effectively in a team environment

- Attention to detail and commitment to quality

- Proactive and results-oriented

- Willingness to learn and adapt to new technologies

I am confident that I can leverage my knowledge, skills, and dedication to make a significant contribution to your organization as a Creping Machine Operator.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Creping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Creping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Creping Machine Operators set up, operate, and maintain creping machines to produce paper or non-woven products. They are responsible for the quality of the finished product, ensuring it meets specifications and customer requirements. Creping Machine Operators are typically responsible for performing the following tasks:

1. Machine Operation

Operate creping machines to produce paper or non-woven products

- Set up and adjust the machine according to production requirements

- Monitor the machine during operation and make adjustments as needed

- Unload finished products from the machine

2. Quality Control

Inspect the finished products to ensure they meet quality specifications

- Identify and correct defects in the product

- Keep records of quality control checks

- Work with other departments to resolve quality issues

3. Machine Maintenance

Inspect and perform basic maintenance on creping machines

- Clean and lubricate the machine

- Replace worn parts

- Troubleshoot and resolve minor mechanical problems

4. Safety

Follow all safety procedures and regulations

- Wear appropriate personal protective equipment

- Keep the work area clean and organized

- Report any safety hazards to the supervisor

Interview Tips

Preparing for an interview can be stressful, but with the right tips and tricks, you can increase your chances of success. Here are some tips to help you ace your interview for a job as Creping Machine Operator:

1. Research the Company

Before the interview, take some time to learn about the company you are applying to. This will show the interviewer that you are interested in the position and that you have taken the time to prepare for the interview.

- Visit the company’s website to learn about their products, services, and culture.

- Read news articles and press releases about the company.

- Check the company’s social media pages to get a sense of their brand and values.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about specific examples that you can use to illustrate your skills and experience.

- Practice answering questions about your background, your skills, and your experience with creping machines.

- Make sure your answers are clear, concise, and relevant.

3. Dress Appropriately

First impressions matter, so it is important to dress appropriately for your interview. For a job as Creping Machine Operator, you should dress in business casual attire.

- Choose clean, pressed clothes that are comfortable and professional.

- Avoid wearing clothes that are too revealing, too tight, or too casual.

- Make sure your shoes are clean and in good condition.

4. Be Polite and Enthusiastic

Throughout the interview, it is important to be polite and enthusiastic. This will show the interviewer that you are interested in the position and that you are eager to learn more about the company.

- Greet the interviewer with a firm handshake and a smile.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be respectful of the interviewer’s time and answer questions honestly and thoroughly.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Creping Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.