Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Crimping Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Crimping Press Operator so you can tailor your answers to impress potential employers.

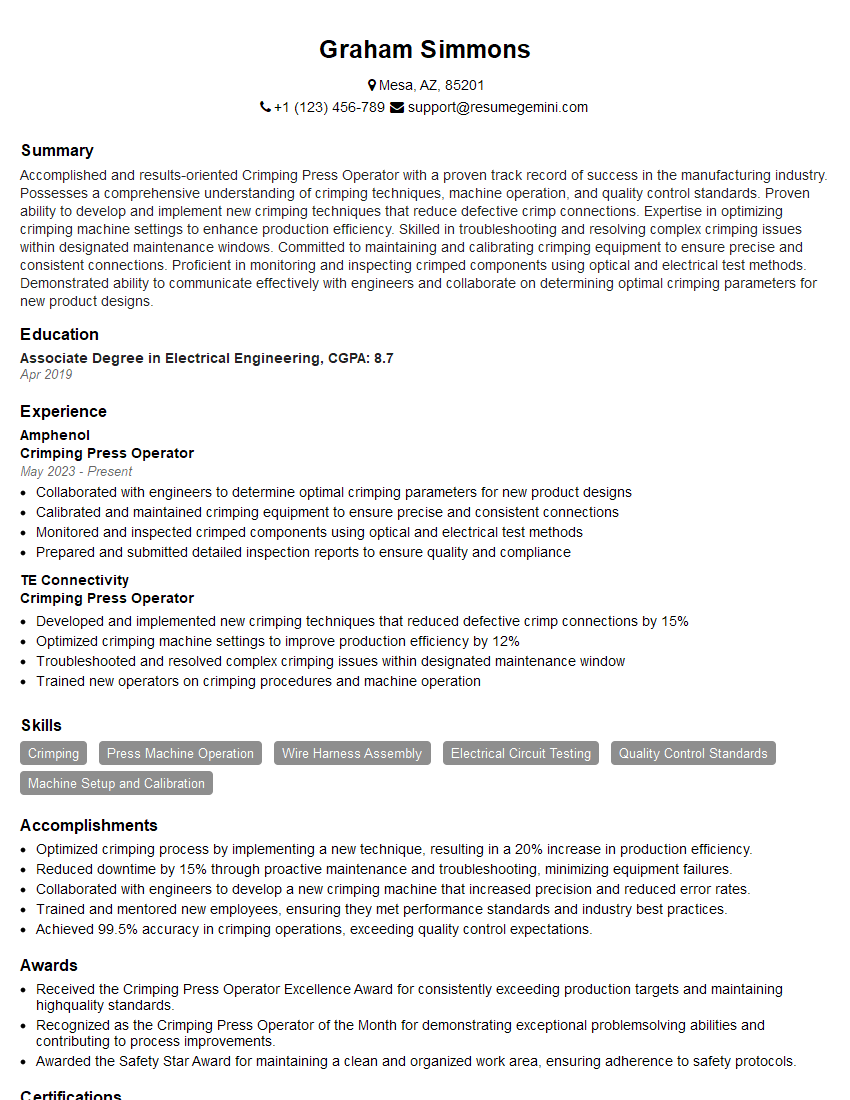

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crimping Press Operator

1. How do you measure the force or pressure applied by a crimping press?

To measure the force or pressure applied by a crimping press, I would use a force gauge or pressure transducer. The force gauge or pressure transducer would be connected to the crimping press and would measure the amount of force or pressure being applied during the crimping process.

2. What is the difference between manual and automatic crimping presses?

Manual Crimping Presses

- Operated by hand

- Lower production rates

Automatic Crimping Presses

- Powered by electricity or compressed air

- Higher production rates

- Greater precision and repeatability

3. What are the different types of crimping dies?

- Open barrel dies

- Closed barrel dies

- Progressive dies

- Turret dies

4. What factors affect the quality of a crimp?

- The type of crimping press

- The type of crimping die

- The force applied during crimping

- The temperature of the crimping process

- The quality of the wire and terminals being crimped

5. What are the most common problems that occur during the crimping process?

- Misaligned dies

- Incorrect crimping force

- Poor quality wire and terminals

- Improper crimping technique

6. How do you troubleshoot a crimping press?

To troubleshoot a crimping press, I would first check the power supply and the air pressure (if the press is pneumatic). I would then check the crimping dies for any damage or wear. I would also check the crimping force and the temperature of the crimping process. If any of these factors are not correct, I would adjust them accordingly.

7. How do you maintain a crimping press?

To maintain a crimping press, I would follow the manufacturer’s instructions for maintenance. I would also perform regular inspections of the press to identify any potential problems. I would also keep a log of all maintenance and repairs performed on the press.

8. What safety precautions should be taken when operating a crimping press?

- Wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Keep hands and fingers away from the crimping area.

- Do not operate the press if it is damaged or malfunctioning.

- Follow all manufacturer’s instructions for safe operation.

9. What are the different types of crimping tools?

- Manual crimping tools

- Semi-automatic crimping tools

- Automatic crimping tools

- Hydraulic crimping tools

- Pneumatic crimping tools

10. What are the advantages of using a crimping tool over a soldering iron?

- Crimping is a faster process than soldering.

- Crimping is a more reliable process than soldering.

- Crimping does not require the use of flux or solder.

- Crimping does not produce fumes or smoke.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crimping Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crimping Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

1. Crimping Operations:

– Operate a crimping press to crimp electrical wires and cables to specifications. – Select and install appropriate dies and crimp heads based on wire size and connector type. – Monitor crimping parameters such as pressure, temperature, and cycle time to ensure optimal crimps.2. Quality Control:

– Inspect crimps for defects using visual inspection and testing equipment. – Maintain documentation of crimping operations, including crimp specifications and quality control results. – Identify and resolve any quality issues to ensure compliance with industry standards.3. Machine Maintenance:

– Perform routine inspections and maintenance of the crimping press and related equipment. – Clean and lubricate moving parts to ensure smooth operation and prevent breakdowns. – Calibrate and adjust the press as needed to maintain accuracy and quality.4. Safety and Compliance:

– Adhere to established safety protocols and use appropriate personal protective equipment (PPE). – Maintain a clean and organized work area to minimize hazards. – Monitor compliance with industry regulations and environmental guidelines. ## Interview Tips To ace the interview for a Crimping Press Operator position, follow these tips:1. Preparation:

– Research the company and the specific role you are applying for. – Practice answering common interview questions related to crimping operations, quality control, and machine maintenance. – Familiarise yourself with industry standards and best practices.2. Confidence and Enthusiasm:

– Demonstrate confidence in your abilities and enthusiasm for the role. – Highlight your experience and skills, but be humble and willing to learn new things. – Show that you are passionate about quality and precision.3. Technical Knowledge:

– Showcase your technical knowledge of crimping processes, crimp head types, and quality control methods. – Explain how you ensure the accuracy and consistency of crimps. – Discuss your understanding of machine maintenance and safety protocols.4. Problem-Solving and Attention to Detail:

– Emphasize your ability to identify and resolve quality issues promptly and effectively. – Share examples of how you have identified and corrected errors in crimping operations. – Demonstrate your attention to detail and commitment to delivering high-quality products.5. Teamwork and Communication:

– Highlight your ability to work independently and as part of a team. – Explain how you communicate with supervisors, quality inspectors, and other team members to ensure smooth operations. – Emphasize your commitment to collaborating with others to achieve common goals. By following these tips, candidates can increase their chances of acing the interview for a Crimping Press Operator position and demonstrating their suitability for the role.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crimping Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.