Are you gearing up for a career in Cross Cut Saw Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cross Cut Saw Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

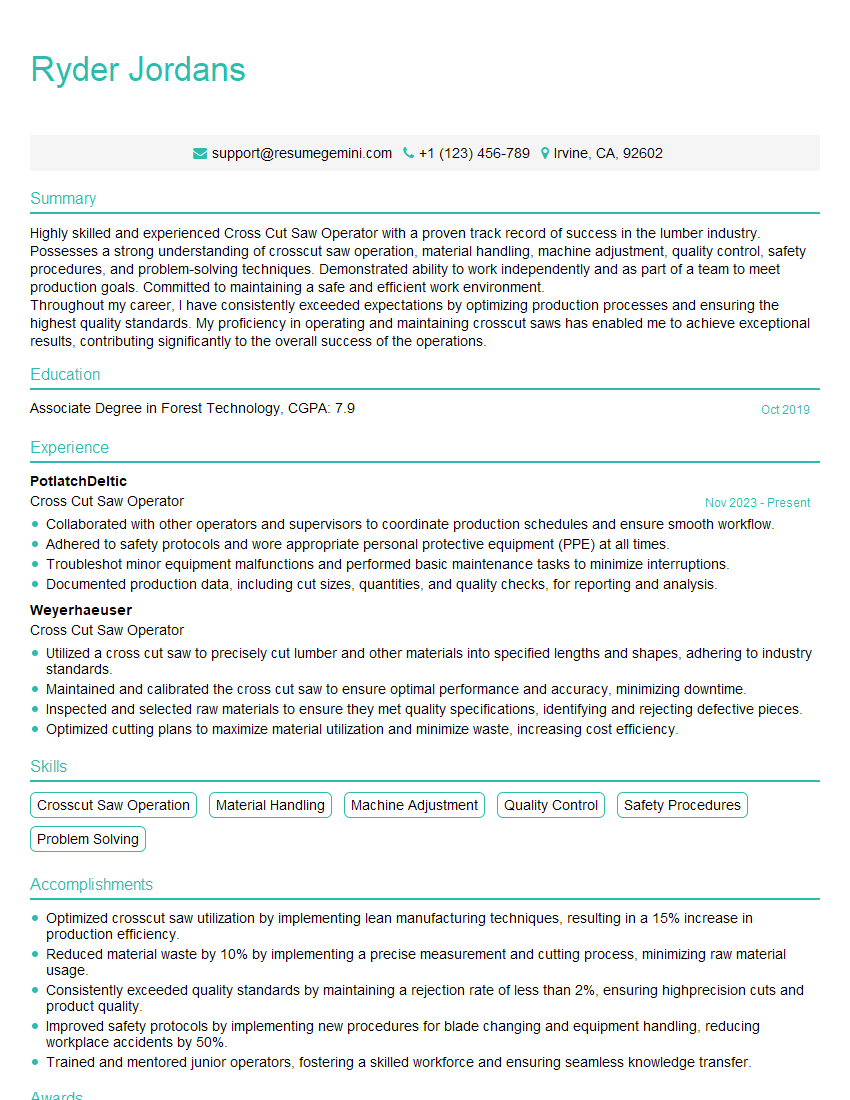

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cross Cut Saw Operator

1. What are the key safety precautions that you take while operating a cross cut saw?

I always prioritize safety when operating a cross cut saw. Here are some key precautions I take:

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, gloves, and a dust mask.

- Ensure that the saw is properly maintained and inspected regularly.

- Check the blade for damage or cracks before each use.

- Secure the workpiece firmly to prevent it from moving during cutting.

- Maintain a safe working distance from the blade.

- Keep the work area clean and free of debris.

- Be aware of the potential for kickback and take precautions to minimize the risk.

2. How do you determine the correct blade for the material you are cutting?

Choosing the correct blade is crucial for efficient and safe cutting. I consider the following factors:

Material Type:

- Different materials require specific blade types. For example, carbide-tipped blades are suitable for cutting hard materials like metal, while abrasive blades are better for cutting softer materials like wood.

Blade Size:

- The blade size should be proportionate to the thickness of the material being cut.

Number of Teeth:

- Blades with more teeth produce finer cuts, while blades with fewer teeth are more aggressive and suitable for rough cutting.

3. What are the common causes of binding in a cross cut saw?

Binding occurs when the blade becomes stuck in the material, which can be dangerous. Here are some common causes:

- Using a dull or damaged blade.

- Cutting too quickly or applying excessive pressure.

- Cutting through knots or other hard areas in the material.

- Not feeding the material smoothly through the saw.

- Insufficient lubrication.

4. How do you troubleshoot blade vibration?

Blade vibration can affect the quality of cuts and cause discomfort to the operator:

- Inspect the blade for any damage or imbalance.

- Check if the blade is securely mounted on the saw.

- Ensure that the saw is properly aligned and calibrated.

- Inspect the bearings and belts for any signs of wear or damage.

- Make sure the workpiece is securely clamped or held.

- Reduce the cutting speed or feed rate.

5. What techniques do you use to achieve precise and accurate cuts?

Precision and accuracy are essential in cross cutting. I employ the following techniques:

- Use sharp, high-quality blades.

- Properly align and calibrate the saw.

- Secure the workpiece firmly and use a fence or guide to ensure straight cuts.

- Mark the cutting line clearly on the workpiece.

- Cut slowly and carefully, observing the blade’s alignment with the cutting line.

- Double-check the measurements and adjust the saw settings as needed.

6. How do you maintain and store a cross cut saw properly?

Proper maintenance and storage extend the life and performance of a cross cut saw:

- Clean the saw thoroughly after each use, removing sawdust and debris.

- Lubricate the moving parts regularly.

- Inspect the blade for damage and sharpen or replace it as needed.

- Store the saw in a dry, clean, and temperature-controlled environment.

- Cover the saw to protect it from dust and moisture.

7. What factors influence the cutting speed of a cross cut saw?

The cutting speed is determined by several factors:

- Blade material and design.

- Material being cut.

- Saw power and torque.

- Cutting depth.

- Feed rate.

8. How do you handle and dispose of sawdust generated by cross cutting?

Sawdust disposal is important for safety and environmental compliance:

- Use a dust collection system to minimize the spread of sawdust.

- Collect sawdust in designated containers and dispose of it properly according to local regulations.

- Avoid burning sawdust as it can release harmful gases.

9. What are the potential hazards associated with cross cut saw operation?

Cross cut saws pose several potential hazards:

- Blade lacerations or amputations.

- Flying debris.

- Electrical shocks.

- Noise-induced hearing loss.

- Repetitive motion injuries.

10. How do you stay up-to-date on the latest advancements and best practices in cross cut saw operation?

To stay current, I:

- Attend industry workshops and training programs.

- Read technical journals and articles.

- Network with other cross cut saw operators.

- Seek feedback from experienced professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cross Cut Saw Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cross Cut Saw Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cross Cut Saw Operator is responsible for operating and maintaining a cross cut saw, a machine used to cut materials like wood, plastic, and metal. Their key responsibilities include:

1. Saw Operation

Operate and control the cross cut saw to perform various cutting operations.

- Set up and adjust the saw for different materials and cutting requirements.

- Monitor the saw’s operation and make adjustments as necessary to ensure precise and efficient cutting.

2. Material Handling

Handle and load materials onto and off the saw.

- Position and secure materials for cutting to achieve desired results.

- Ensure materials meet specifications before and after cutting.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshoot issues with the cross cut saw.

- Lubricate, clean, and inspect the saw regularly to keep it in good working condition.

- Identify and resolve operational problems to minimize downtime and maintain productivity.

4. Safety and Compliance

Follow safety protocols and ensure compliance with regulations.

- Wear appropriate personal protective equipment (PPE) and adhere to safety guidelines.

- Maintain a clean and organized work area to minimize hazards.

Interview Tips

1. Research the Company and Position

Before the interview, take time to thoroughly research the company, its industry, and the specific role you’re applying for. This will demonstrate your interest in the opportunity and help you align your answers with the company’s needs.

- Visit the company’s website to learn about their mission, values, and recent projects.

- Read industry news and articles to stay up-to-date on trends and best practices.

2. Prepare Your Responses

Take some time to prepare your answers to common interview questions. Consider your experiences and how they align with the job requirements. Practice delivering your answers clearly and concisely. Here are some example questions and an outline for a strong response:

- Question: Tell us about your experience operating cross cut saws.

- Outline:

- Start with a brief overview of your experience and the types of cross cut saws you’ve operated.

- Provide specific examples of projects or tasks where you successfully used a cross cut saw.

- Highlight any skills or techniques that you’re particularly proficient in.

- Quantify your results whenever possible, such as the number of cuts you made per hour or the accuracy of your cuts.

3. Be Enthusiastic and Confident

During the interview, it’s important to project a positive and enthusiastic attitude. Show the interviewer that you’re genuinely interested in the role and that you believe in your abilities. Speak confidently about your skills and experience, but avoid sounding arrogant.

- Make eye contact with the interviewer and smile when appropriate.

- Sit up straight and maintain good posture.

- Use positive body language, such as nodding and leaning forward slightly to show engagement.

4. Ask Thoughtful Questions

At the end of the interview, take the opportunity to ask thoughtful questions. This shows the interviewer that you’re engaged and that you’re interested in learning more about the company and the role. Prepare a few questions in advance, such as:

- What are the most important qualities you’re looking for in a Cross Cut Saw Operator?

- What are the biggest challenges facing the company right now?

- What opportunities for professional development are available to employees?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cross Cut Saw Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.