Are you gearing up for a career in Crown Assembly Machine Set-Up Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Crown Assembly Machine Set-Up Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

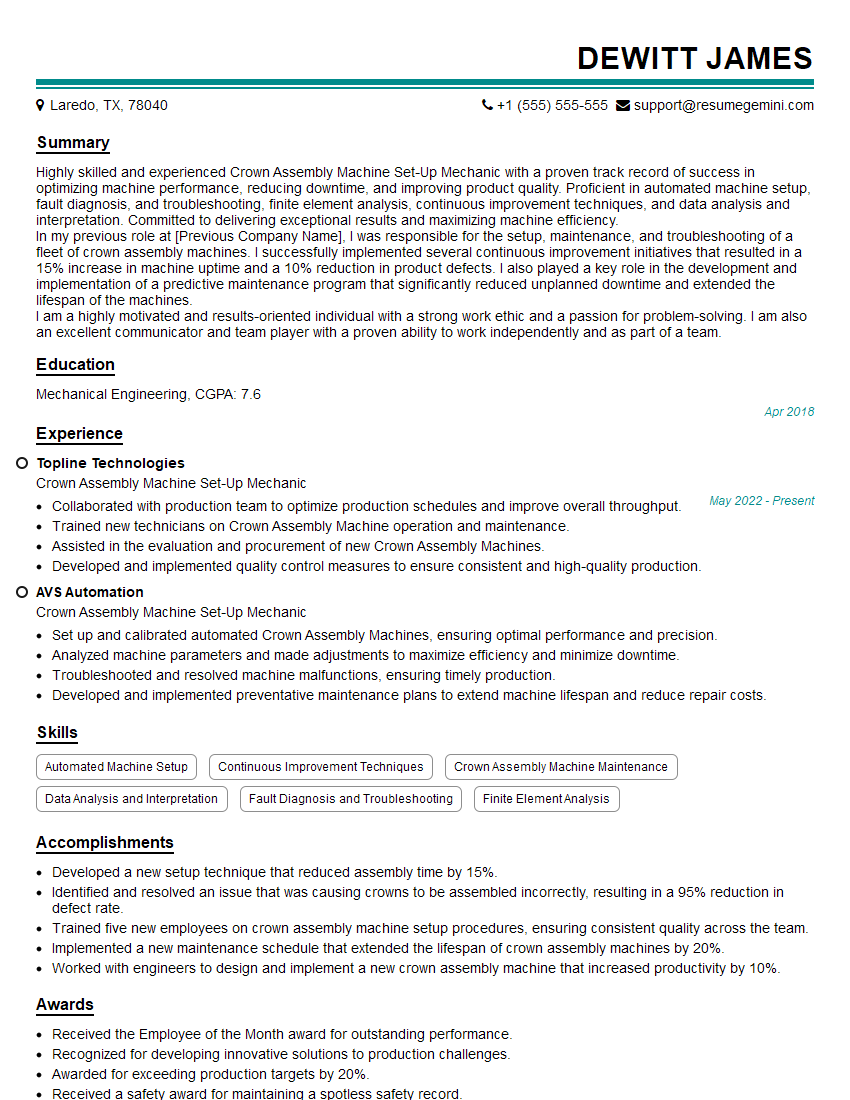

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crown Assembly Machine Set-Up Mechanic

1. Describe the key responsibilities of a Crown Assembly Machine Set-Up Mechanic.

- Set up, calibrate, maintain, and repair Crown assembly machines.

- Troubleshoot and resolve machine malfunctions.

- Inspect and adjust machinery to ensure optimal performance.

- Monitor production processes and make adjustments as needed.

- Train and supervise other machine operators.

2. What are the common types of Crown assembly machines and their specific functions?

Types of Crown assembly machines

- Rotary Crown Assembly Machines: High-speed machines used for assembling large crowns.

- Linear Crown Assembly Machines: Versatile machines suitable for various crown sizes and shapes.

- Semi-Automatic Crown Assembly Machines: Operator-assisted machines for low-volume production.

- Fully-Automatic Crown Assembly Machines: Highly efficient machines for high-volume production.

Specific functions of Crown assembly machines

- Feeding and orienting crown components.

- Assembling components into complete crowns.

- Inserting and crimping fasteners.

- Quality control and inspection.

3. Describe the process of setting up a Crown assembly machine and the key parameters to consider.

- Refer to the machine manual and technical specifications.

- Calibrate the machine’s sensors and actuators.

- Adjust the machine’s feed rate, assembly pressure, and other parameters.

- Ensure proper alignment of all machine components.

- Test the machine’s operation and make fine adjustments as needed.

4. What are the routine maintenance tasks required for Crown assembly machines?

- Clean and lubricate machine components.

- Inspect belts, chains, and gears for wear and tear.

- Replace worn or damaged parts.

- Calibrate sensors and actuators regularly.

- Monitor machine performance and make adjustments as needed.

5. How do you troubleshoot common malfunctions in Crown assembly machines?

- Identify the symptoms of the malfunction.

- Inspect the machine for any visible damage or defects.

- Review the machine’s error codes and diagnostic messages.

- Perform tests to isolate the faulty component.

- Repair or replace the faulty component as necessary.

6. What is the importance of preventive maintenance in Crown assembly machine operations?

- Reduces machine downtime and production delays.

- Extends the machine’s lifespan and improves reliability.

- Ensures consistent product quality and reduces defects.

- Improves safety by preventing potential hazards.

- Optimizes machine performance and efficiency.

7. What are the safety precautions that must be observed when operating Crown assembly machines?

- Wear appropriate personal protective equipment.

- Keep the work area clean and free of debris.

- Ensure proper ventilation and lighting.

- Never operate the machine without proper training.

- Follow lockout/tagout procedures when servicing or repairing the machine.

8. What is your experience with troubleshooting electrical systems in Crown assembly machines?

- Using multimeters, oscilloscopes, and other diagnostic tools to identify electrical faults.

- Tracing electrical circuits and testing components for continuity, resistance, and voltage.

- Repairing or replacing faulty electrical components, such as sensors, actuators, and wiring.

- Understanding electrical schematics and wiring diagrams.

- Ensuring compliance with electrical safety regulations and codes.

9. How do you prioritize tasks and manage multiple projects simultaneously in a fast-paced manufacturing environment?

- Assessing the criticality and urgency of tasks.

- Creating a prioritized task list and allocating resources accordingly.

- Delegating tasks to team members and monitoring their progress.

- Communicating effectively with colleagues and supervisors.

- Staying organized and maintaining a clean and efficient work area.

10. What are your strengths and weaknesses as a Crown Assembly Machine Set-Up Mechanic?

Strengths:- Strong technical skills and knowledge of Crown assembly machines.

- Excellent troubleshooting and problem-solving abilities.

- Detail-oriented and committed to quality.

- Proficient in electrical troubleshooting and repair.

- Excellent communication and teamwork skills.

- Limited experience with the latest automated Crown assembly machines.

- Need to improve my documentation skills.

- Can sometimes be too meticulous and spend excessive time on details.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crown Assembly Machine Set-Up Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crown Assembly Machine Set-Up Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Crown Assembly Machine Set-Up Mechanic plays a critical role in ensuring efficient and productive operations for the organization. Their primary responsibilities encompass the following:

1. Machine Set-Up and Calibration

Expertly configure and calibrate crown assembly machines to meet production specifications and quality standards.

- Install and adjust machine components, ensuring optimal performance and precision.

- Troubleshoot and resolve machine malfunctions, minimizing downtime and production disruptions.

2. Maintenance and Repairs

Protect the longevity and efficiency of crown assembly machines through preventative maintenance practices.

- Conduct regular inspections, identifying potential issues and implementing proactive solutions.

- Overhaul and repair machines as needed, ensuring their reliability and productivity.

3. Quality Control and Monitoring

Maintain the highest quality standards for crown assemblies through rigorous inspection processes.

- Inspect assemblies for defects, deviations, and conformance to specifications.

- Implement quality control measures to identify and rectify errors, ensuring customer satisfaction.

4. Training and Support

Contribute to the overall knowledge and skillset of the team by sharing expertise on crown assembly operations.

- Provide guidance and training to operators, ensuring they have the necessary skills to operate machines effectively.

- Collaborate with other departments to optimize production processes and resolve technical issues.

Interview Tips

To ace an interview for the Crown Assembly Machine Set-Up Mechanic position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your eagerness to join the organization by researching its history, values, and industry standing.

- Familiarize yourself with the latest advancements in crown assembly technology and manufacturing practices.

- Read industry publications and attend webinars to stay abreast of trends and best practices.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to showcase your relevant experience and skills that align with the job requirements.

- Quantify your accomplishments and provide specific examples that demonstrate your expertise.

- Emphasize your ability to work autonomously and as part of a team to achieve production goals.

3. Be Prepared for Technical Questions

Anticipate questions related to crown assembly machine operation, maintenance, and troubleshooting.

- Review common machine components, their functions, and potential failure points.

- Prepare for questions on your experience with specific software and automation systems.

4. Ask Thoughtful Questions

Engage with the interviewer by asking thoughtful questions that demonstrate your interest and understanding of the role.

- Inquire about the company’s long-term growth plans and how the position contributes to those goals.

- Ask about the training and development opportunities available to employees.

5. Practice and Stay Professional

Practice your responses to common interview questions and ensure you maintain a positive and professional demeanor throughout the interview.

- Be confident and articulate your answers clearly and concisely.

- Dress appropriately and arrive on time for your interview, demonstrating your respect for the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Crown Assembly Machine Set-Up Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.