Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Crown Wheel Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

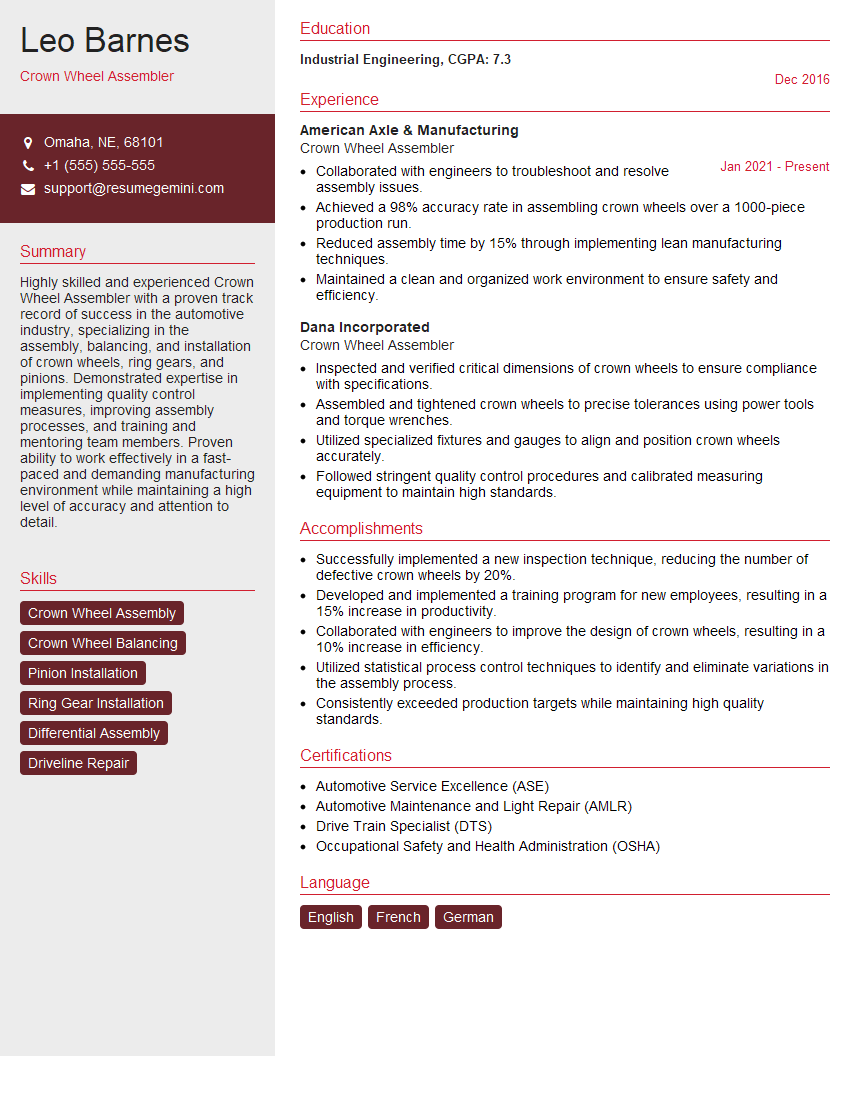

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crown Wheel Assembler

1. Explain the step-by-step process of assembling a crown wheel and pinion?

Sample Answer:

- Clean and inspect all components for wear or damage

- Apply sealant to the pinion shaft and insert it into the crown wheel

- Mount the crown wheel and pinion assembly on the differential case

- Apply preload to the pinion bearing using a torque wrench

- Install the differential cover and fill with lubricant

2. Describe the different types of crown wheels and their applications?

- Straight-cut crown wheels: Used in low-speed applications where noise is not a concern

- Helical crown wheels: Used in high-speed applications where noise reduction is important

- Hypoid crown wheels: Used in applications where the pinion shaft is offset from the center of the crown wheel, allowing for a wider range of gear ratios

3. What are the most common causes of crown wheel and pinion failure?

- Excessive wear due to improper lubrication or overloading

- Bearing failure due to contamination or improper installation

- Tooth breakage due to excessive torque or impact loading

4. How do you calculate the correct backlash for a crown wheel and pinion assembly?

Sample Answer:

- Measure the crown wheel and pinion tooth thicknesses

- Subtract the pinion tooth thickness from the crown wheel tooth thickness

- Multiply the result by the number of pinion teeth

- The backlash should be within the manufacturer’s specified range

5. What are the different methods of inspecting a crown wheel and pinion assembly?

- Visual inspection for wear or damage

- Tooth contact pattern analysis using a dial indicator or gear tooth contact gauge

- Noise and vibration analysis using a stethoscope or vibration analyzer

6. How do you adjust the preload on a crown wheel and pinion assembly?

Sample Answer:

- Loosen the pinion bearing locknut

- Turn the pinion bearing adjusting nut until the desired preload is achieved

- Tighten the pinion bearing locknut

7. What are the safety precautions that must be followed when working with crown wheels and pinions?

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection

- Use proper tools and techniques to avoid injury

- Be aware of the potential hazards of rotating machinery

8. How do you troubleshoot a noisy crown wheel and pinion assembly?

- Check the backlash and adjust if necessary

- Inspect the tooth contact pattern and adjust the pinion angle or crown wheel offset

- Check the bearing preload and adjust if necessary

- Inspect the crown wheel and pinion for wear or damage

9. What are the latest trends in crown wheel and pinion design and manufacturing?

- Use of advanced materials for improved durability and reduced noise

- Computer-aided design and manufacturing for more precise components

- Development of new tooth profiles for improved efficiency and load capacity

10. How do you stay up-to-date with the latest advancements in crown wheel and pinion technology?

Sample Answer:

- Attend industry conferences and workshops

- Read technical articles and journals

- Network with other professionals in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crown Wheel Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crown Wheel Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Crown Wheel Assembler, you would be responsible for assembling and testing crown wheels, ensuring they meet the required specifications. Your key responsibilities would include:

1. Assembly

Assembling crown wheels according to engineering drawings and specifications.

- Selecting and preparing components, such as bearings, gears, and seals.

- Using precision tools and equipment to assemble components.

- Applying lubricants and sealants to ensure proper operation.

2. Testing

Testing assembled crown wheels to verify their functionality and performance.

- Conducting visual inspections for defects or damage.

- Using test equipment to measure dimensions, tolerances, and clearances.

- Operating crown wheels under load to assess their performance.

3. Troubleshooting

Identifying and resolving any issues or defects that arise during assembly or testing.

- Analyzing failures and determining root causes.

- Implementing corrective actions to improve assembly processes or component performance.

- Documenting troubleshooting activities and findings.

4. Quality Control

Maintaining quality standards throughout the assembly and testing process.

- Adhering to established quality procedures and specifications.

- Performing regular inspections and audits to ensure compliance.

- Identifying and reporting any quality concerns or deviations.

Interview Tips

To ace your interview for a Crown Wheel Assembler position, follow these tips:

1. Research the Company and Position

Demonstrate your interest and preparation by researching the company and the specific role. Familiarize yourself with the company’s products, services, and industry standing. Understand the key responsibilities and requirements of the Crown Wheel Assembler position.

- Visit the company’s website and social media pages.

- Read industry news and articles related to crown wheel assembly.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Quantify your accomplishments using specific examples and metrics whenever possible. Showcase your proficiency in crown wheel assembly, testing, and troubleshooting. Describe any certifications or training you have completed.

- Example: “In my previous role, I assembled over 500 crown wheels per month, meeting all quality standards.”

3. Demonstrate Attention to Detail and Precision

Crown Wheel Assemblers must possess a high level of attention to detail and precision. Highlight your ability to follow instructions meticulously, work accurately, and maintain a clean and organized work area. Provide examples of your commitment to quality and precision in your previous roles.

- Example: “I have a keen eye for detail and am meticulous in my work. In my previous job, I was responsible for assembling high-precision medical devices, where accuracy was paramount.”

4. Prepare for Technical Questions

Be prepared to answer technical questions about crown wheel assembly and testing. Review common assembly techniques, quality control procedures, and troubleshooting methods. Study the principles of gear design and operation, as well as the materials and components used in crown wheel assemblies.

- Example: Prepare to discuss the importance of backlash and preload in crown wheel assemblies.

5. Practice Your Communication Skills

Effective communication is essential for Crown Wheel Assemblers who may need to interact with engineers, quality control personnel, and other team members. Practice your communication skills by rehearsing your answers to common interview questions and preparing clear and concise explanations of technical concepts.

- Example: Practice describing the assembly process of a crown wheel in a clear and logical manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Crown Wheel Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Crown Wheel Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.