Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Croze Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

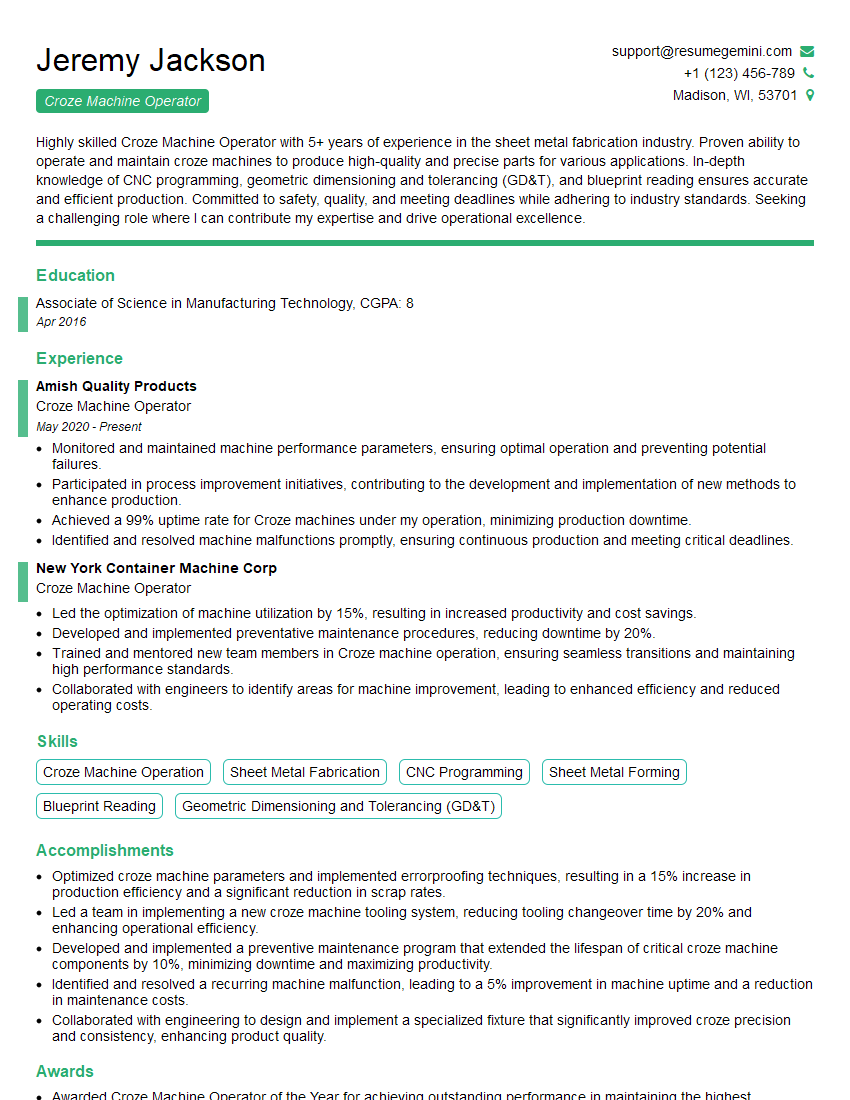

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Croze Machine Operator

1. What are the different types of croze machine operators?

- Automatic Croze Machine Operator – operates automatic croze machines that bore grooves into wooden barrels.

- Manual Croze Machine Operator – manually operates croze machines to bore grooves into wooden barrels.

- Croze Machine Setup Operator – sets up and adjusts croze machines for different sizes and types of barrels.

- Croze Machine Maintenance Operator – performs maintenance and repairs on croze machines.

2. What are the key responsibilities of a Croze Machine Operator?

Job Duties and Responsibilities:

- Loads and unloads barrels from the machine.

- Operates the machine to bore grooves into the barrels.

- Inspects the barrels for defects.

- Keeps the machine clean and well-maintained.

- May also be responsible for setting up and adjusting the machine.

Safety and Compliance:

- Follows all safety regulations and procedures.

- Wears appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Reports any accidents or injuries to the supervisor.

Quality Control:

- Conducts inspections on barrels to ensure they meet quality standards.

- Rejects barrels that do not meet quality standards.

- Records inspection results and reports any defects to the supervisor.

Maintenance and Troubleshooting:

- Performs basic maintenance on the machine, such as cleaning and lubrication.

- Troubleshoots and repairs minor machine malfunctions.

- Reports major machine malfunctions to the supervisor.

3. What are the qualifications typically required to become a Croze Machine Operator?

- High school diploma or equivalent.

- No formal training or certification is required, but most employers prefer to hire candidates with experience operating croze machines.

- Basic math and measurement skills.

- Good hand-eye coordination.

- Ability to work independently and as part of a team.

- Strong work ethic and attention to detail.

4. What are the most important skills for a Croze Machine Operator?

- Machine operation skills.

- Quality control skills.

- Maintenance and troubleshooting skills.

- Safety and compliance knowledge.

- Teamwork and communication skills.

5. What are the different types of woodworking machines?

- Saws

- Planers

- Jointers

- Lathes

- Drills

- Sanders

- Routers

6. What are the safety precautions that must be taken when operating woodworking machines?

- Always wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Never operate a machine that is not properly guarded.

- Always keep your hands away from the cutting blade.

- Never reach over or behind a running machine.

- Always unplug the machine before performing any maintenance or repairs.

7. What are the different types of wood joints?

- Butt joint

- Edge joint

- Lap joint

- Miter joint

- Mortise and tenon joint

- Dado joint

- Dovetail joint

8. What are the different types of wood finishes?

- Oil-based finishes

- Water-based finishes

- Lacquer finishes

- Shellac finishes

- Polyurethane finishes

9. What are the different types of woodworking tools?

- Hand tools

- Power tools

- Stationary tools

10. What are the different types of woodworking projects?

- Furniture

- Cabinets

- Flooring

- Moldings

- Toys

- Signs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Croze Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Croze Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Croze Machine Operator

A Croze Machine Operator is a highly skilled professional responsible for operating a croze machine to cut grooves into the woodwork of barrels and casks. They play a crucial role in preparing these vessels for holding liquids securely and sealing them effectively.

1. Machine Operation and Maintenance

Croze Machine Operators are experts in operating and maintaining croze machines, ensuring their proper functioning and producing high-quality cuts.

- Set up and calibrate the croze machine according to specifications.

- Safely operate the machine to cut precise grooves into cask staves.

- Perform regular maintenance and troubleshooting to keep the machine in optimal condition.

2. Material Handling and Preparation

Handling and preparing materials, such as cask staves, is an integral part of their responsibilities.

- Inspect and select cask staves to ensure they meet quality standards.

- Prepare staves by measuring and marking the correct positions for grooves.

- Load and unload staves into the croze machine efficiently.

3. Quality Control and Assurance

Quality is paramount, and Croze Machine Operators are committed to maintaining it.

- Monitor the croze cutting process to ensure accuracy and precision.

- Inspect the finished grooves for defects and non-conformities.

- Maintain accurate records of production and quality control.

4. Safety Compliance and Environmental Awareness

Safety and environmental consciousness are essential aspects of their role.

- Adhere to established safety protocols and wear appropriate protective gear.

- Follow environmental regulations and dispose of waste materials responsibly.

- Maintain a clean and organized work area.

Interview Preparation Tips for Croze Machine Operator Candidates

Preparing for a Croze Machine Operator interview requires a thorough understanding of the role and showcasing your relevant skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry landscape. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and LinkedIn profile.

- Read industry publications and articles.

- Attend industry events or webinars.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating croze machines and your experience in material handling and quality control. Quantify your accomplishments whenever possible.

- Describe your experience in setting up and calibrating croze machines.

- Provide examples of how you maintained high-quality standards and resolved production issues.

3. Demonstrate Safety Awareness and Environmental Consciousness

Safety and environmental compliance are crucial in this role. Highlight your commitment to these aspects.

- Discuss your understanding of safety protocols and your experience in adhering to them.

- Explain your knowledge of environmental regulations and your practices for responsible waste disposal.

4. Prepare Questions for the Interviewer

Asking intelligent questions shows your engagement and interest in the role. Prepare questions about the company’s production processes, quality control standards, and opportunities for professional growth.

- Inquire about the company’s production goals and timelines.

- Ask about the quality control measures in place and how they are maintained.

Next Step:

Now that you’re armed with the knowledge of Croze Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Croze Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini