Are you gearing up for an interview for a Crozer Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Crozer Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

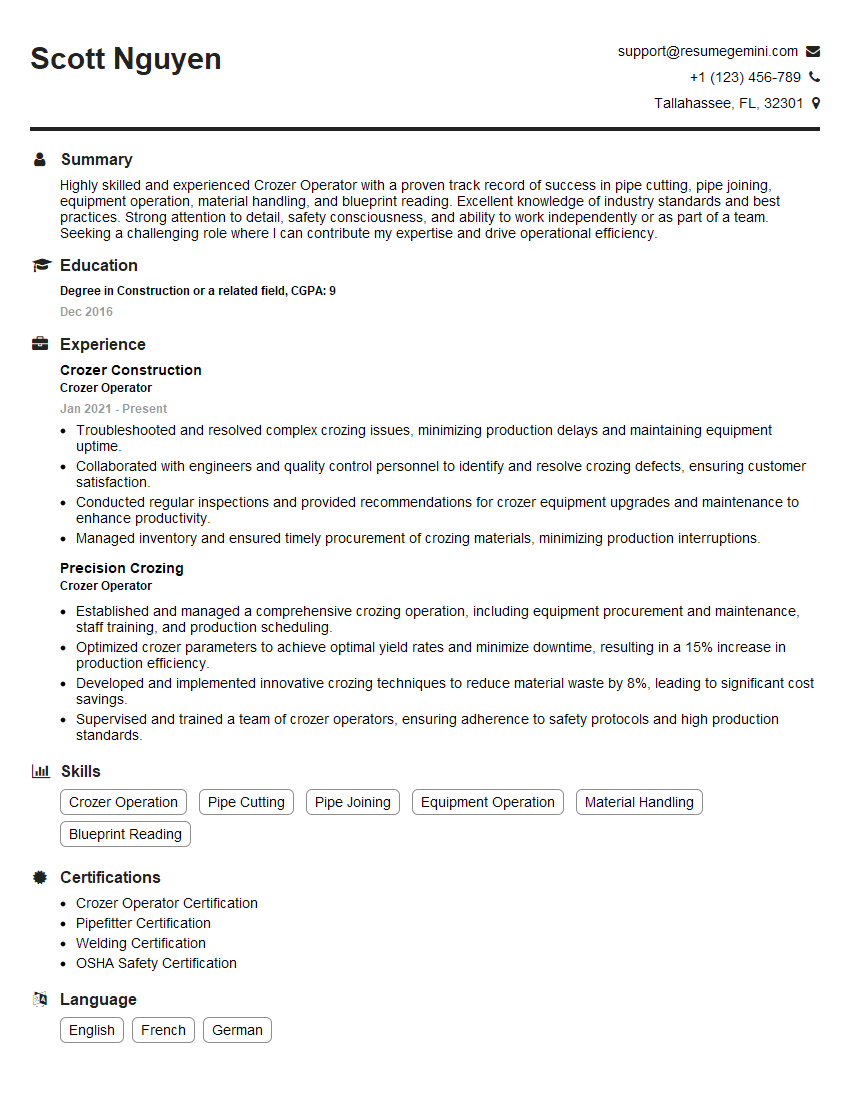

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crozer Operator

1. Explain the process of starting and stopping a crozer?

To start a crozer, the following steps are generally followed:

- Ensure the machine is on a stable and level surface.

- Check the fuel level and fill it up if necessary.

- Turn on the fuel valve.

- Set the throttle to the desired speed.

- Pull the recoil starter rope to start the engine.

To stop a crozer, the following steps are generally followed:

- Set the throttle to the low position.

- Turn off the fuel valve.

- Allow the engine to run until it runs out of fuel.

2. What are the different types of crozers and their uses?

Crawler Crozers

- Used for tasks that require a high level of precision and maneuverability.

- Equipped with tracks instead of wheels, providing better stability and traction on uneven surfaces.

Wheeled Crozers

- More versatile and can be used for a wider range of applications.

- Less maneuverable than crawler crozers, but can travel faster on smooth surfaces.

Zero-Turn Crozers

- Offer high maneuverability and are ideal for mowing complex areas with obstacles.

- Capable of making tight turns without leaving uncut grass behind.

3. What are the safety precautions that should be taken when operating a crozer?

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Be aware of your surroundings and keep children and pets away from the operating area.

- Inspect the crozer before each use and ensure it is in good working condition.

- Never operate the crozer under the influence of alcohol or drugs.

- Follow the manufacturer’s instructions for safe operation and maintenance.

4. How do you adjust the cutting height of a crozer?

The cutting height of a crozer can usually be adjusted by following these steps:

- Locate the adjustment lever or knob on the crozer.

- Move the lever or knob to the desired cutting height setting.

- Tighten the lever or knob to secure the adjustment.

The cutting height typically ranges from 1 inch to 4 inches, allowing you to customize the cut to suit different grass conditions and preferences.

5. What is the difference between a mulching crozer and a side-discharge crozer?

- Mulching Crozer:

- Chops grass clippings into small pieces and distributes them back onto the lawn.

- Provides nutrients to the soil and helps retain moisture.

- Side-Discharge Crozer:

- Discharges grass clippings to the side of the crozer.

- Requires more frequent emptying of the grass catcher.

6. How do you troubleshoot a crozer that is not starting?

- Check the fuel level and ensure there is sufficient fuel.

- Inspect the spark plug and replace it if necessary.

- Clean the air filter to ensure proper airflow.

- Check the fuel line for any leaks or blockages.

- Inspect the battery terminals and clean them if they are corroded.

7. What is the recommended maintenance schedule for a crozer?

- Daily: Check the fuel level, inspect the cutting blades, and clean the exterior of the crozer.

- Weekly: Sharpen or replace the cutting blades as needed.

- Monthly: Change the oil and oil filter, clean the air filter, and grease all moving parts.

- Yearly: Perform a thorough inspection of the crozer, including the engine, transmission, and electrical system.

8. How do you improve the efficiency of a crozer?

- Keep the cutting blades sharp to reduce resistance.

- Set the cutting height at the appropriate level for the grass conditions.

- Avoid cutting wet grass, as it can clog the cutting deck and slow down the crozer.

- Use a mulching attachment to return nutrients to the soil and reduce waste.

9. What are the common causes of crozer accidents?

- Using the crozer on an incline without proper safety measures.

- Operating the crozer under the influence of alcohol or drugs.

- Not wearing appropriate safety gear, such as earplugs and safety glasses.

- Failing to maintain the crozer properly.

10. How do you identify and replace a damaged cutting blade on a crozer?

Identifying a damaged cutting blade involves inspecting it for any nicks, cracks, or bends. To replace a damaged blade, follow these steps:

- Disconnect the spark plug wire to prevent accidental starting.

- Tilt the crozer to access the cutting deck.

- Locate the blade bolt and loosen it using a wrench.

- Remove the damaged blade and replace it with a new one.

- Tighten the blade bolt securely.

Replace all blades simultaneously to ensure proper balance and performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crozer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crozer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Crozer Operator plays a crucial role in ensuring the smooth and efficient production of crozer-soldered products. The key job responsibilities of a Crozer Operator typically include:

1. Crozing Operation

Preparing and operating the crozing machine to join metal components using a crozing process.

- Setting up and calibrating the crozing machine according to specifications.

- Loading and aligning the metal components to be crozed.

- Applying crozing material and initiating the crozing cycle.

2. Quality Control

Monitoring and inspecting the crozed joints to ensure they meet quality standards.

- Conducting visual inspections and dimensional measurements.

- Identifying and correcting defects or discrepancies.

- Maintaining records and reporting quality issues.

3. Equipment Maintenance

Performing regular maintenance and upkeep of the crozing equipment.

- Lubricating, cleaning, and adjusting the machine.

- Inspecting and replacing worn or damaged parts.

- Troubleshooting and resolving technical issues.

4. Production Support

Assisting in other production-related tasks as needed.

- Loading and unloading materials from the production line.

- Maintaining a clean and organized work area.

- Following safety protocols and adhering to company policies.

Interview Tips

Preparing for an interview for a Crozer Operator position can enhance your chances of success. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and products. Research the specific role and its responsibilities to demonstrate your interest and knowledge.

- Visit the company’s website and read about their mission, products, and services.

- Review the job description thoroughly and identify key responsibilities and qualifications.

2. Highlight Relevant Experience and Skills

Emphasize your experience in crozing operations, quality control, and equipment maintenance. Showcase your technical skills, attention to detail, and ability to work independently.

- Quantify your accomplishments using specific metrics, such as the number of crozed joints produced per hour or the percentage of defects reduced.

- Provide examples of how you resolved technical issues or improved production efficiency.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your experience, skills, and motivations. Practice your responses to ensure they are clear, concise, and tailored to the job.

- Example:

- Tell me about your experience in crozing operations.

- How do you ensure the quality of crozed joints?

- What steps do you take to maintain and troubleshoot crozing equipment?

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare questions that demonstrate your understanding of the company and the position.

- Example:

- Can you provide more details about the production process and the challenges involved?

- What are the company’s plans for future growth and innovation in crozing technology?

- What opportunities are there for professional development and advancement within the company?

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time. Maintain a positive and confident demeanor throughout the interview process.

Next Step:

Now that you’re armed with the knowledge of Crozer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Crozer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini