Are you gearing up for an interview for a Crusher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Crusher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

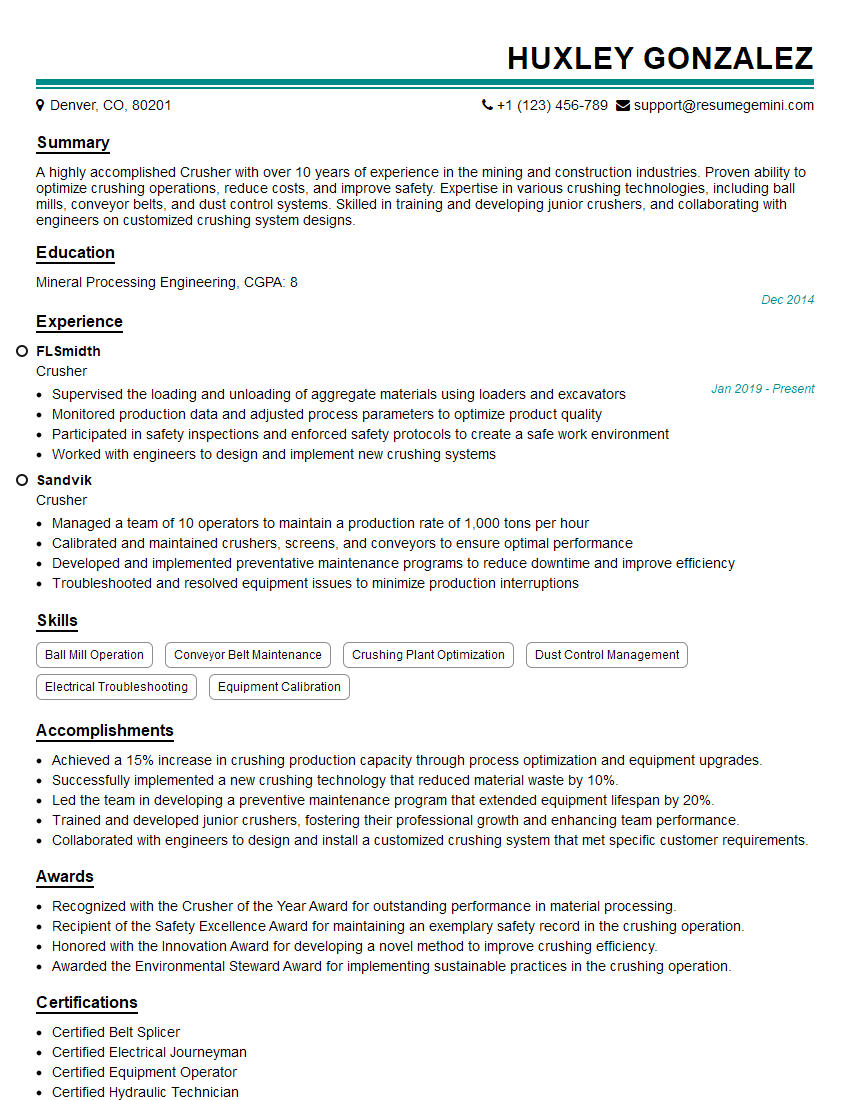

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher

1. What tools and techniques do you use for crushing and screening aggregates?

I use a variety of tools and techniques for crushing and screening aggregates, including:

- Jaw crushers

- Impact crushers

- Cone crushers

- Vibrating screens

- Trommel screens

2. How do you determine the appropriate settings for your crushing and screening equipment?

I determine the appropriate settings for my crushing and screening equipment based on the following factors:

- The type of aggregate being processed

- The desired size and shape of the finished product

- The capacity of the equipment

- The operating conditions

3. What are the most important safety precautions to take when operating crushing and screening equipment?

The most important safety precautions to take when operating crushing and screening equipment include:

- Wearing appropriate personal protective equipment

- Keeping the equipment in good working order

- Following the manufacturer’s instructions

- Being aware of your surroundings

- Never operating the equipment under the influence of alcohol or drugs

4. What are the most common problems that you encounter when operating crushing and screening equipment?

The most common problems that I encounter when operating crushing and screening equipment include:

- Blockages

- Overheating

- Wear and tear

- Electrical problems

- Hydraulic problems

5. How do you troubleshoot and repair crushing and screening equipment?

I troubleshoot and repair crushing and screening equipment by following these steps:

- Identifying the problem

- Determining the cause of the problem

- Repairing the problem

- Testing the equipment to ensure that it is working properly

6. What are the preventive maintenance tasks that you perform on crushing and screening equipment?

I perform the following preventive maintenance tasks on crushing and screening equipment:

- Inspecting the equipment regularly

- Lubricating the equipment

- Replacing worn parts

- Calibrating the equipment

- Keeping the equipment clean

7. What are the most important quality control procedures that you follow when operating crushing and screening equipment?

The most important quality control procedures that I follow when operating crushing and screening equipment include:

- Sampling the aggregate

- Testing the aggregate

- Adjusting the equipment to meet the desired specifications

- Documenting the quality control results

8. What are the environmental regulations that apply to crushing and screening operations?

The environmental regulations that apply to crushing and screening operations include:

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

- The Comprehensive Environmental Response, Compensation, and Liability Act

- The Toxic Substances Control Act

9. What are the best practices for minimizing the environmental impact of crushing and screening operations?

The best practices for minimizing the environmental impact of crushing and screening operations include:

- Using dust collectors

- Using water sprays

- Enclosing the equipment

- Storing the aggregate in a covered area

- Recycling the aggregate

10. What are the future trends in crushing and screening technology?

The future trends in crushing and screening technology include:

- The use of automation

- The use of sensors

- The use of artificial intelligence

- The development of new materials

- The development of new processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Crushers are responsible for operating and maintaining crushing equipment used in a variety of industries, such as mining, construction, and recycling. They must ensure that the equipment is operating safely and efficiently to maximize production and minimize downtime.

1. Equipment Operation

Crushers are responsible for the safe and efficient operation of crushing equipment, including jaw crushers, cone crushers, and impact crushers. They must be able to identify and troubleshoot any problems that may arise with the equipment and make necessary repairs.

- Monitor equipment operation and make adjustments as needed

- Identify and troubleshoot any problems that may arise

- Perform routine maintenance and repairs

2. Production Monitoring

Crushers are responsible for monitoring production and ensuring that it meets the desired specifications. They must be able to identify any factors that may affect production, such as the size and hardness of the material being crushed, and make necessary adjustments.

- Monitor production and compare it to desired specifications

- Identify any factors that may affect production

- Make necessary adjustments to maintain desired production levels

3. Quality Control

Crushers are responsible for ensuring that the crushed material meets the desired quality specifications. They must be able to identify any defects in the material and make necessary adjustments to the crushing process.

- Identify any defects in the crushed material

- Make necessary adjustments to the crushing process to improve quality

- Ensure that the crushed material meets the desired specifications

4. Safety

Crushers must be able to work safely in a variety of environments, including around heavy machinery and hazardous materials. They must be familiar with all safety regulations and be able to follow them at all times.

- Follow all safety regulations

- Work safely around heavy machinery and hazardous materials

- Identify and avoid any potential hazards

Interview Tips

Preparing for a job interview can be a daunting task, but it is important to remember that the interviewer is just as interested in getting to know you as you are in learning about the job. By following these tips, you can increase your chances of making a great impression and landing the job.

1. Research the Company and the Position

Before you go to an interview, it is important to do your research on the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific skills and experience required for the job. You can find this information on the company’s website, social media pages, and job boards.

- Visit the company’s website to learn about their history, mission, and values

- Follow the company on social media to get a sense of their culture and recent news

- Read job boards to learn about the specific skills and experience required for the position

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked, such as “Tell me about yourself” and “Why are you interested in this job?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself that includes your skills, experience, and why you are interested in the job

- Think about why you are interested in the specific company and position

- Practice answering questions about your strengths, weaknesses, and how you handle stress

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the job.

- Choose clothing that is clean, pressed, and appropriate for the office environment

- Arrive for your interview 10-15 minutes early to give yourself time to relax and collect your thoughts

- Be polite and respectful to the receptionist and anyone else you meet

4. Be Yourself and Be Enthusiastic

It is important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your skills and experience, and show the interviewer why you are the best person for the job.

- Be yourself and be genuine

- Show the interviewer your enthusiasm for the job

- Be confident in your skills and experience

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crusher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!