Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Crusher Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

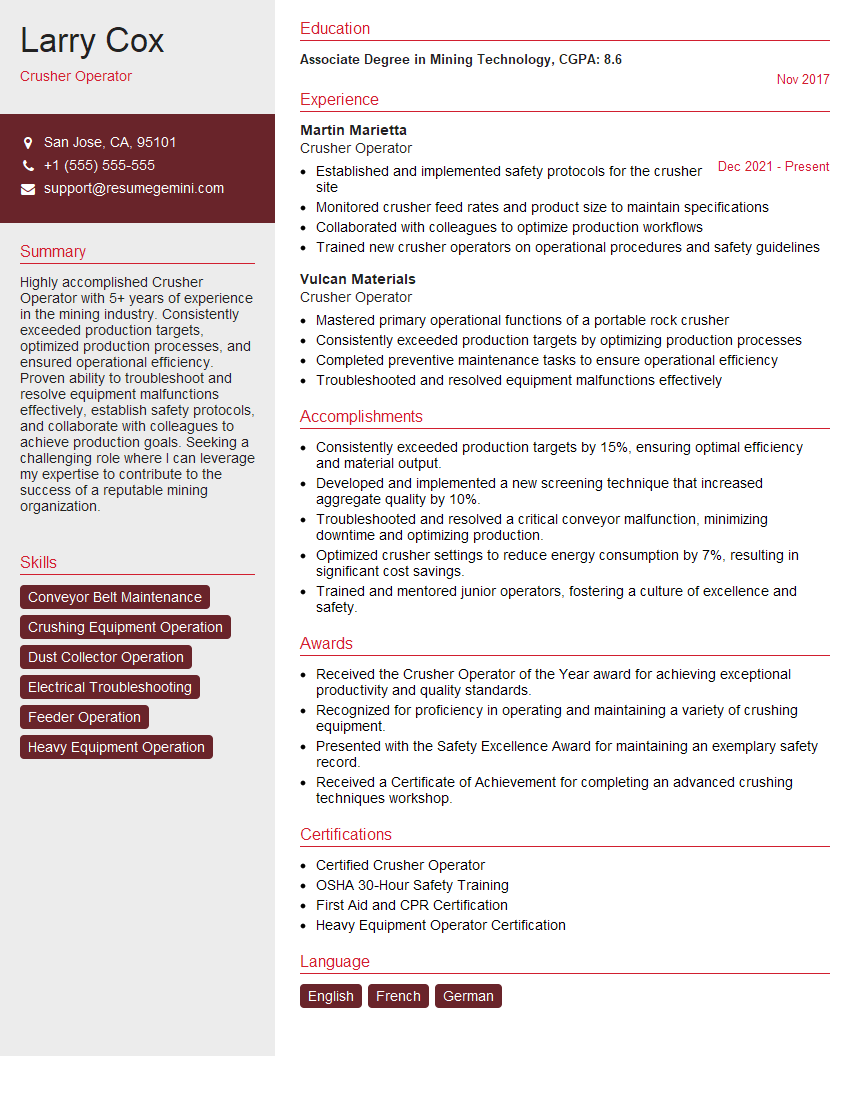

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher Operator

1. What are the key responsibilities of a Crusher Operator?

- Operating and maintaining crushing equipment to reduce the size of materials.

- Ensuring the smooth and efficient operation of the crushing plant.

- Monitoring equipment performance, identifying potential issues, and taking corrective actions.

- Maintaining a clean and organized work area, adhering to safety regulations.

- Communicating effectively with other team members, supervisors, and clients.

2. How do you ensure the safety of yourself and others while operating a crusher?

PPE and Work Area

- Wearing appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and gloves.

- Maintaining a clean and organized work area, free from tripping hazards and debris.

Equipment Operation

- Following established safety procedures and manufacturer’s guidelines for operating the crusher.

- Inspecting equipment before each use, identifying any potential issues and taking necessary actions.

- Remaining alert and aware of surroundings, ensuring a safe distance from moving parts.

Emergency Preparedness

- Being familiar with emergency procedures, evacuation routes, and first-aid protocols.

- Participating in regular safety training and drills.

3. Can you describe the different types of crushers used in the industry and their applications?

- Jaw Crushers: Used for primary crushing of large rocks and minerals, producing coarse particles.

- Gyratory Crushers: Conical-shaped crushers used for secondary and tertiary crushing, producing smaller and more uniform particles.

- Cone Crushers: Similar to gyratory crushers, used for fine crushing and producing a more cubical shape.

- Impact Crushers: Use high-speed impact to break down materials, often used for recycling applications.

- Hammer Mills: Utilize rotating hammers to crush materials, suitable for softer materials like coal and gypsum.

4. How do you determine the optimal settings for a crusher based on the desired product size and material characteristics?

- Analyzing the material’s properties, such as hardness, toughness, and abrasiveness.

- Determining the desired product size and gradation.

- Consulting with equipment manufacturers or technical experts for recommended settings.

- Experimenting with different settings and monitoring the results to optimize performance.

- Adjusting settings as needed to achieve the desired product quality and production rate.

5. What are some common maintenance tasks performed on crushers, and how do you ensure they are carried out effectively?

- Regular Inspections: Visually inspecting equipment for any wear or damage.

- Lubrication: Greasing and oiling moving parts to minimize friction and wear.

- Adjustments: Tightening bolts, aligning components, and adjusting settings as necessary.

- Replacements: Replacing worn or damaged parts, such as jaws, hammers, or screens.

- Troubleshooting: Diagnosing and resolving any operational issues or malfunctions.

To ensure effectiveness, maintenance tasks should be scheduled regularly, documented, and carried out by qualified technicians.

6. How do you optimize the efficiency and productivity of a crushing plant?

- Equipment Optimization: Ensuring crushers are properly set up, maintained, and calibrated.

- Feed Control: Regulating the flow and consistency of material entering the crusher.

- Screen Management: Selecting and maintaining appropriate screens to achieve the desired product size.

- Process Monitoring: Tracking key performance indicators, such as production rate, energy consumption, and product quality.

- Continuous Improvement: Regularly reviewing processes and implementing improvements based on data analysis and feedback.

7. What troubleshooting techniques do you employ when encountering issues with a crusher?

- Identify the Symptom: Determine the specific problem or deviation from normal operation.

- Gather Data: Collect information about the issue, such as when it occurred, operating conditions, and any recent changes.

- Inspect Equipment: Visually inspect the crusher and its components for any visible signs of damage or wear.

- Check Settings: Verify that the crusher settings are correct and appropriate for the material being processed.

- Consult Resources: Refer to manufacturer’s manuals, technical experts, or colleagues for guidance.

- Test and Verify: Implement potential solutions and monitor the results to confirm that the issue has been resolved.

8. How do you handle emergency situations in a crushing plant?

- Assess the Situation: Quickly evaluate the situation and identify any immediate hazards.

- Follow Emergency Procedures: Adhere to established protocols for shutdown, evacuation, and response.

- Communicate Effectively: Inform supervisors, colleagues, and emergency services as necessary.

- Control the Scene: Isolate the affected area, secure equipment, and prevent unauthorized access.

- Investigate and Resolve: Once the situation is under control, investigate the cause and implement corrective actions to prevent recurrence.

9. How do you stay up-to-date on advancements and best practices in the crushing industry?

- Industry Publications: Reading trade magazines, technical journals, and industry reports.

- Conferences and Webinars: Attending industry events, workshops, and online seminars.

- Networking: Connecting with other professionals, attending industry meetups, and joining professional organizations.

- Equipment Manufacturers: Consulting with manufacturers for product updates, technical advancements, and training programs.

- Continuing Education: Pursuing additional certifications, courses, or workshops to enhance knowledge and skills.

10. Why are you interested in this Crusher Operator position, and what makes you a suitable candidate?

I am eager to join your organization as a Crusher Operator because I possess the necessary skills, experience, and passion for this role.

My strong understanding of crusher operations, maintenance, and safety protocols makes me well-equipped to contribute effectively to your team.

Furthermore, my commitment to optimizing productivity, ensuring equipment longevity, and adhering to the highest safety standards aligns perfectly with your company’s values.

I am a highly motivated and results-oriented individual with a proven track record of success in the crushing industry. I am confident that my technical expertise and dedication would make me a valuable asset to your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Crusher Operator plays a vital role in mining and construction operations. Their primary responsibilities revolve around operating heavy machinery, monitoring the production process, and ensuring efficient and safe operations.

1. Operate Crusher Equipment

Crusher Operators are responsible for managing the operation of crushers, including primary and secondary crushers. They adjust settings, monitor performance, and troubleshoot any issues to optimize production.

2. Monitor Production

Operators oversee the production process to ensure efficiency and quality. They monitor material flow, adjust feed rates, and inspect the final product to meet specifications.

3. Maintain Equipment

Routine maintenance is crucial for the smooth operation of crushing equipment. Operators perform daily inspections, lubricate components, and conduct minor repairs to keep the equipment in optimal condition.

4. Troubleshooting and Adjustments

Crusher Operators possess the technical expertise to troubleshoot and rectify any problems that may arise during the crushing process. They identify the root cause, implement adjustments, and minimize downtime.

Interview Tips

Preparing thoroughly for a job interview is essential for success. Here are some tips to help candidates ace the interview for a Crusher Operator position:

1. Research the Company and Role

Demonstrate your interest in the company and the position by researching their history, operations, and the specific requirements of the job. This will help you tailor your answers and show that you’ve taken the time to prepare.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating heavy machinery, particularly crushers. Showcase your troubleshooting abilities, maintenance experience, and understanding of the production process.

3. Prepare for Technical Questions

Anticipate technical questions related to crusher operations, such as crusher types, material characteristics, and production optimization. Study the basics and prepare confident answers.

4. Emphasize Safety and Efficiency

Mining and construction operations prioritize safety and efficiency. Showcase your commitment to working safely and efficiently, reducing downtime, and optimizing production.

5. Dress and Behave Professionally

Dress appropriately for a job interview, typically business casual or business professional. Maintain a positive and professional demeanor throughout the interview.

6. Ask Insightful Questions

Asking well-thought-out questions at the end of the interview demonstrates your interest and engagement. Questions about the company’s growth plans, safety protocols, or industry trends can convey your enthusiasm.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crusher Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!