Feeling lost in a sea of interview questions? Landed that dream interview for Crusher Plant Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Crusher Plant Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

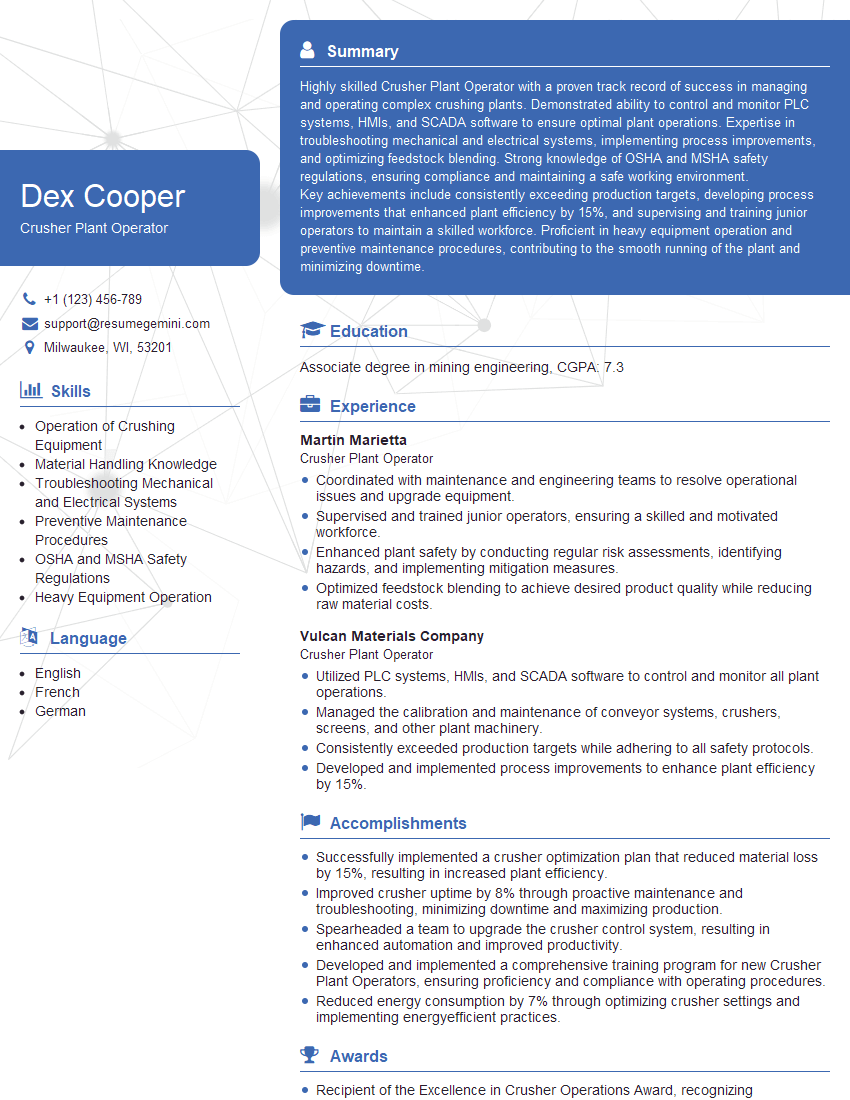

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher Plant Operator

1. What are the important steps involved in setting up a crusher plant?

The following are the steps involved in setting up a crusher plant:

- Identify the raw material source and determine the type of material to be crushed.

- Choose the appropriate crusher for the material and the desired output size.

- Design and build the crusher plant layout, including the location of the crusher, screens, conveyors, and other equipment.

- Install the crusher and other equipment.

- Calibrate the crusher and set the operating parameters.

- Test the crusher plant to ensure it is operating properly.

- Train the operators on the safe and efficient operation of the crusher plant.

2. What are the different types of crushers and their applications?

There are different types of crushers each with its own application:

Jaw Crushers

- Used for primary and secondary crushing.

- Suitable for hard and abrasive materials such as granite, basalt, and concrete.

Gyratory Crushers

- Used for primary and secondary crushing.

- Suitable for hard and medium-hard materials such as granite, limestone, and traprock.

Cone Crushers

- Used for secondary and tertiary crushing.

- Suitable for hard and medium-hard materials such as granite, limestone, and basalt.

Impact Crushers

- Used for secondary and tertiary crushing.

- Suitable for soft to medium-hard materials such as limestone, shale, and coal.

Hammer Mills

- Used for fine crushing.

- Suitable for soft materials such as coal, gypsum, and limestone.

3. How do you maintain and troubleshoot a crusher plant?

Regular maintenance and troubleshooting are essential to ensure the crusher plant operates efficiently and safely:

- Regularly inspect the crusher, screens, conveyors, and other equipment for wear and tear.

- Lubricate all moving parts according to the manufacturer’s recommendations.

- Calibrate the crusher and other equipment regularly to ensure they are operating properly.

- Troubleshoot any problems that occur with the crusher plant, such as blockages, material buildup, or equipment failure.

- Keep a maintenance log to track all maintenance and repairs performed on the crusher plant.

4. What are the safety precautions that need to be taken when operating a crusher plant?

To ensure safety when operating the crusher plant, it’s important to:

- Wear appropriate personal protective equipment (PPE), such as hard hat, safety glasses, earplugs, and gloves.

- Be aware of the location of all emergency stop buttons and know how to use them.

- Never enter the crusher plant while it is operating.

- Keep all guards and safety devices in place.

- Follow all safety procedures and protocols.

5. What are the environmental regulations that apply to the operation of a crusher plant?

Crusher plants must comply with environmental regulations, which may include:

- Air quality regulations to control dust and emissions.

- Water quality regulations to control runoff and prevent pollution.

- Noise regulations to minimize noise levels.

- Waste management regulations to properly dispose of waste materials.

6. What is the role of a crusher plant operator?

The primary responsibilities of a crusher plant operator include:

- Operating and monitoring the crusher plant, including the crusher, screens, conveyors, and other equipment.

- Ensuring the crusher plant is operating safely and efficiently.

- Performing routine maintenance and troubleshooting.

- Calibrating the crusher and other equipment.

- Keeping a maintenance log.

- Following all safety procedures and protocols.

7. What are the qualifications and experience required to be a crusher plant operator?

Typically to be a crusher plant operator, you need:

- A high school diploma or equivalent.

- Experience operating heavy equipment.

- Knowledge of crusher plant operations.

- Understanding of safety procedures and environmental regulations.

8. How do you ensure that the crusher plant is producing the desired product size and quality?

To ensure the crusher plant is producing the desired product size and quality, it is essential to:

- Calibrate the crusher and screens to achieve the desired product size.

- Monitor the crusher plant operation and make adjustments as needed.

- Perform regular quality control checks on the product.

- Keep a record of all calibration and quality control checks.

9. What are the common challenges faced by crusher plant operators?

Some of the common challenges faced by crusher plant operators include:

- Equipment breakdowns and maintenance issues.

- Variations in the quality of the raw material.

- Meeting production targets.

- Ensuring the safety of the plant and personnel.

- Complying with environmental regulations.

10. How do you stay up-to-date on the latest crusher plant technology and best practices?

To stay up-to-date on the latest crusher plant technology and best practices, as a crusher plant operator, it is important to:

- Attend industry conferences and trade shows.

- Read industry publications and technical journals.

- Participate in online forums and discussion groups.

- Consult with equipment manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Crusher Plant Operator is responsible for operating, monitoring, and maintaining equipment used to crush rock and other materials into smaller pieces. Their responsibilities include:

1. Equipment Operation

– Operating crushing equipment, including jaw crushers, gyratory crushers, and cone crushers.

– Setting and adjusting equipment controls to achieve desired product size and quality.

– Troubleshooting and resolving equipment issues to maintain optimal performance.

2. Equipment Maintenance

– Performing routine maintenance tasks, such as lubrication, cleaning, and inspections.

– Identifying and repairing minor equipment malfunctions.

– Coordinating with maintenance personnel for major repairs.

3. Material Handling

– Controlling the flow of materials through the crushing process.

– Ensuring proper material feeding and discharge.

– Monitoring material levels and adjusting equipment settings as needed.

4. Safety and Compliance

– Following all safety protocols and procedures.

– Wearing appropriate personal protective equipment (PPE).

– Maintaining a clean and orderly work area.

Interview Tips

To ace an interview for a Crusher Plant Operator position, candidates should prepare thoroughly and showcase their relevant skills and experience. Here are some tips:

1. Research the Company and Role

– Familiarize yourself with the company’s history, values, and products.

– Study the job description carefully and identify the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

– Emphasize your experience in operating and maintaining crushing equipment.

– Provide specific examples of how you have resolved equipment issues and improved efficiency.

– Demonstrate your knowledge of safety protocols and compliance regulations.

3. Practice Answering Common Interview Questions

– Prepare for questions about your experience, skills, and why you are interested in the role.

– Develop clear and concise answers that highlight your strengths and match the company’s requirements.

4. Prepare Questions for the Interviewer

– Asking thoughtful questions shows your interest in the position and the company.

– Inquire about the company’s growth plans, safety culture, and opportunities for professional development.

5. Demonstrate Enthusiasm and Confidence

– Show your passion for the job and your ability to thrive in a demanding environment.

– Maintain eye contact, speak clearly, and project a positive attitude.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crusher Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!