Are you gearing up for a career in Crusher Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Crusher Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

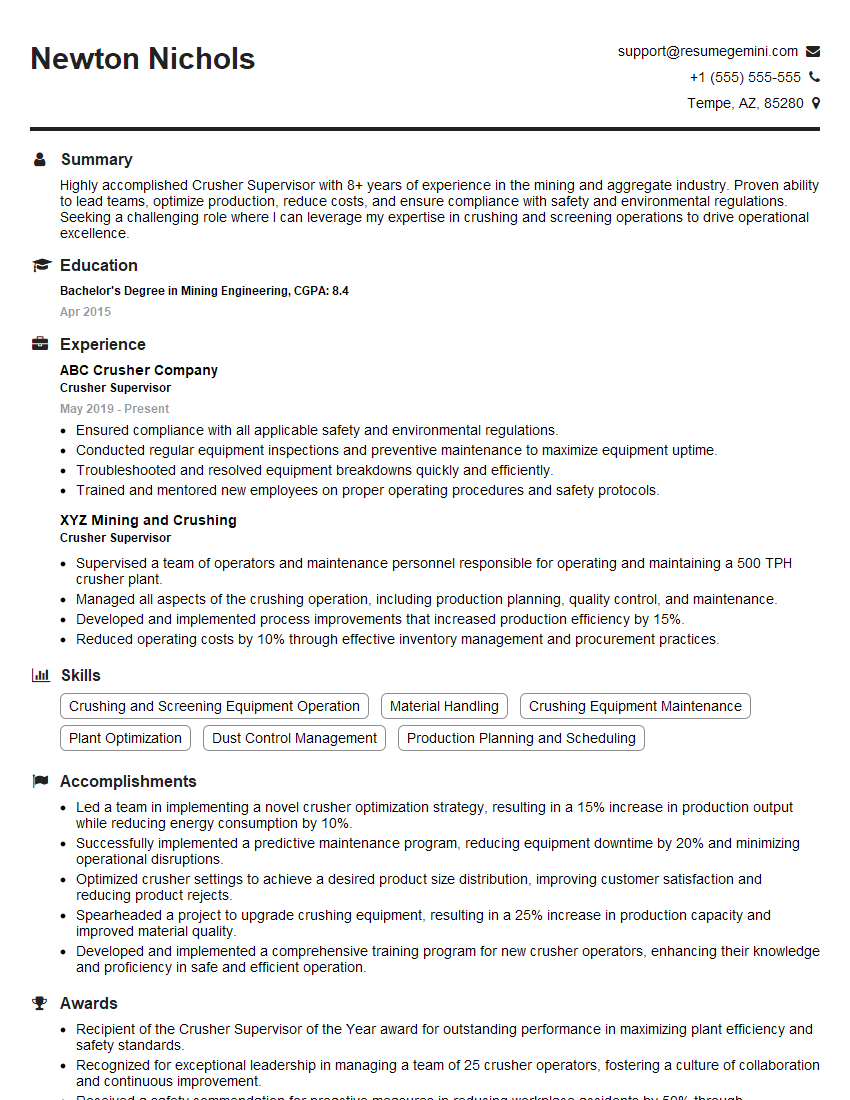

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crusher Supervisor

1. What are the key responsibilities of a Crusher Supervisor?

As a Crusher Supervisor, my primary responsibilities entail:

- Supervising and managing the operation of the crushing plant, ensuring efficient and safe production.

- Monitoring and optimizing the production process, adjusting equipment settings and procedures to maximize output and quality.

- Coordinating with the maintenance team to ensure timely repairs and maintenance of the crushing equipment, minimizing downtime.

- Maintaining a safe and productive work environment, conducting safety briefings, and enforcing safety regulations.

- Training and developing subordinates, providing guidance and mentorship to improve their skills and knowledge.

2. Describe the principles of jaw crushing and how they impact the performance of a jaw crusher.

Crushing Theory

- In jaw crushing, material is compressed between a fixed jaw and a movable jaw that oscillates.

- The shape and size of the product are determined by the gap between the jaws, known as the “setting”.

Performance Factors

- The optimal setting depends on the material characteristics, such as hardness and size distribution.

- Appropriate jaw plate selection (smooth vs. ribbed) affects the crushing efficiency and product shape.

- Jaw crusher performance is also influenced by factors such as speed, stroke, and feed rate.

3. How do you monitor and control the product size and quality in a crushing plant?

To monitor and control product size and quality, I utilize the following techniques:

- Regular sieve analysis to determine the size distribution of the crushed material.

- Visual inspection of the product to assess its quality and consistency.

- Adjustment of crusher settings, such as jaw gap or impactor speed, based on the desired product specifications.

- Calibration and maintenance of screening and sorting equipment to ensure accurate separation of particles.

- Implementation of quality control procedures, including sampling and testing, to ensure compliance with specifications.

4. Explain the importance of proper lubrication and maintenance for crushing equipment.

- Lubrication reduces friction and wear, prolonging the life of bearings, gears, and other moving parts.

- Regular maintenance prevents breakdowns, minimizes downtime, and maintains optimal crusher performance.

- Scheduled inspections identify potential problems early, enabling proactive repairs and reducing the risk of catastrophic failures.

- Proper maintenance contributes to a safer work environment by preventing accidents related to equipment malfunctions.

- Well-maintained equipment operates more efficiently, consuming less energy and producing a higher quality product.

5. What are the common troubleshooting techniques you employ when a crusher is not performing as expected?

- Visually inspect the equipment for any obvious issues, such as loose bolts or damaged components.

- Check sensors and gauges to ensure they are functioning correctly and providing accurate readings.

- Analyze the product quality and size distribution to identify potential problems with crusher settings or wear.

- Review maintenance records to determine if any overdue repairs or adjustments are needed.

- Consult with the equipment manufacturer or technical experts for guidance and support.

6. Describe the safety protocols and procedures you implement in a crushing plant.

- Conduct regular safety briefings and training sessions for all employees.

- Enforce the use of personal protective equipment (PPE), such as hard hats, safety glasses, and earplugs.

- Establish clear work procedures and ensure they are followed diligently.

- Identify and mitigate potential hazards, such as moving machinery, electrical wires, and dust accumulation.

- Provide emergency response plans and train employees on appropriate actions in case of accidents.

7. How do you handle and resolve conflicts or disputes among team members?

- Listen to all perspectives and gather relevant information to understand the situation.

- Facilitate open and respectful communication between the parties involved.

- Identify the root cause of the conflict and work towards addressing it.

- Develop mutually acceptable solutions that prioritize the safety and well-being of all team members.

- Follow up to ensure that the resolution is implemented and effective.

8. Describe your experience with managing and optimizing production in a crushing plant.

In my previous role as Crusher Supervisor at [Company Name], I was responsible for:

- Developing and implementing production schedules to maximize output and efficiency.

- Monitoring production rates and identifying bottlenecks to improve throughput.

- Adjusting crusher settings and operating parameters to optimize product quality and minimize waste.

- Coordinating with other departments, such as maintenance and logistics, to ensure smooth production flow.

- Training and motivating team members to achieve production targets and maintain high standards.

9. What are your strategies for reducing downtime and maximizing equipment utilization?

- Implement a proactive maintenance schedule to identify and address potential issues before they cause breakdowns.

- Train operators on proper equipment handling and maintenance techniques.

- Maintain a spare parts inventory to minimize downtime in case of component failures.

- Cross-train employees to ensure coverage during absences or emergencies.

- Monitor equipment performance and identify areas for improvement to minimize downtime.

10. Explain your understanding of the environmental regulations applicable to crushing operations.

- Dust and particulate emission control measures, such as dust collectors and water sprays.

- Noise pollution mitigation techniques, such as sound barriers and silencers.

- Water management and disposal practices to prevent contamination.

- Waste management and recycling to minimize environmental impact.

- Regular inspections and monitoring to ensure compliance with regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crusher Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crusher Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Crusher Supervisor is responsible for overseeing the operation and maintenance of the crushing plant, ensuring that it operates safely, efficiently, and in compliance with all applicable regulations.

1. Production Management

Supervises and coordinates the activities of the crushing plant, ensuring that production targets are met and quality standards are maintained.

- Plans and schedules crushing operations, including equipment setup, raw material allocation, and production targets.

- Monitors production output and makes adjustments to optimize efficiency and productivity.

2. Safety and Compliance

Ensures a safe working environment for all employees and contractors, and complies with all applicable safety regulations.

- Conducts safety inspections of the crushing plant, equipment, and work areas.

- Implements and enforces safety policies and procedures.

- Investigates accidents and incidents, and takes corrective actions to prevent recurrence.

3. Equipment Maintenance and Troubleshooting

Maintains and troubleshoots crushing equipment, ensuring that it operates efficiently and reliably.

- Conducts routine maintenance and repairs on crushers, conveyors, and other equipment.

- Identifies and resolves equipment malfunctions, minimizing downtime and maximizing production.

- Collaborates with maintenance technicians to ensure timely and effective repairs.

4. Team Management

Leads and motivates a team of operators and maintenance technicians, ensuring that they are trained, safe, and productive.

- Provides training and development opportunities for team members.

- Conducts performance evaluations and provides feedback.

- Empowers team members to make decisions and take ownership of their work.

Interview Tips

To prepare for your Crusher Supervisor interview, it is important to have a deep understanding of the job responsibilities and to demonstrate your relevant skills and experience.

1. Research the Company and the Position

Research the company’s history, values, and the specific responsibilities of the Crusher Supervisor position. This will help you tailor your answers to the interviewer’s questions and show that you have a genuine interest in the role.

2. Highlight Your Production Management Experience

Emphasize your ability to plan and schedule crushing operations, monitor production output, and make adjustments to optimize efficiency. Provide specific examples of how you have successfully managed production in previous roles.

3. Emphasize Your Safety and Compliance Expertise

Demonstrate your knowledge of safety regulations and your commitment to creating a safe work environment. Highlight your experience in conducting safety inspections, implementing safety policies, and investigating accidents.

4. Showcase Your Equipment Maintenance Skills

Describe your experience in maintaining and troubleshooting crushing equipment. Provide examples of how you have identified and resolved equipment malfunctions, minimizing downtime and maximizing production.

5. Emphasize Your Team Management Abilities

Highlight your leadership and motivation skills. Provide examples of how you have led and developed a team, empowered team members, and fostered a positive and productive work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crusher Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.