Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Crystal Calibrator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Crystal Calibrator so you can tailor your answers to impress potential employers.

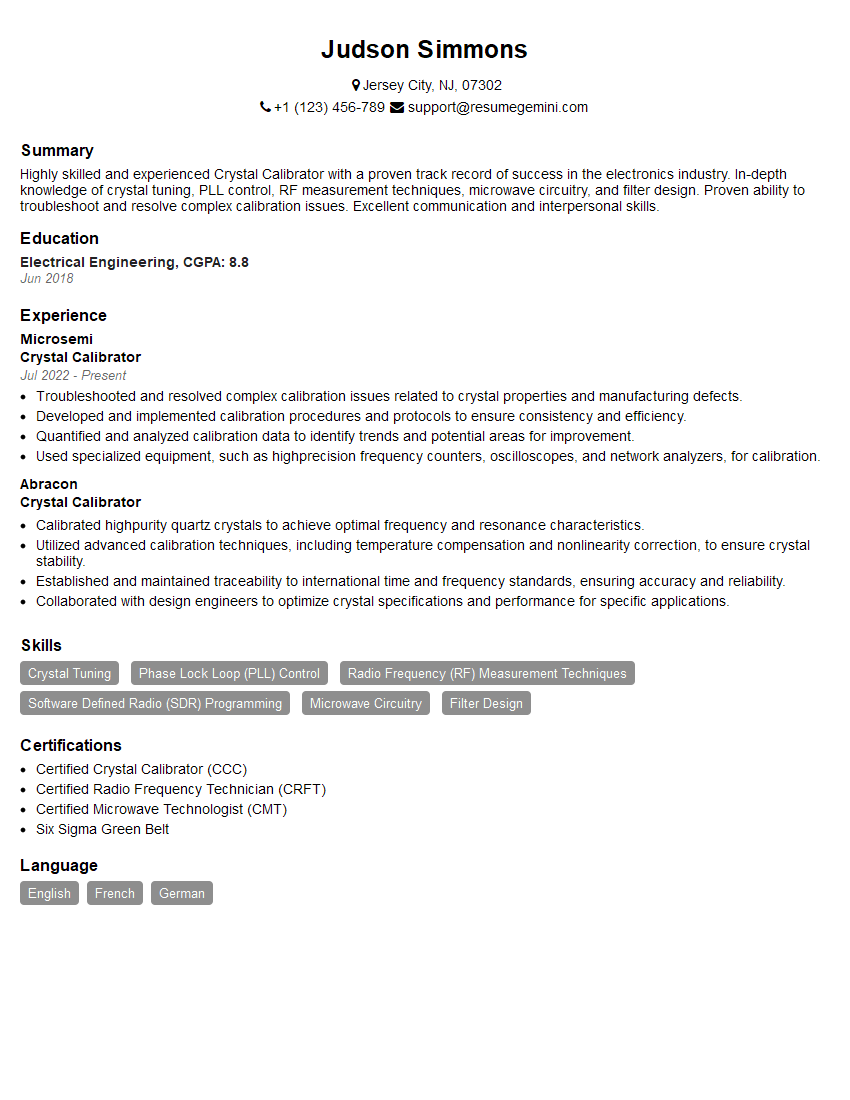

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crystal Calibrator

1. Explain the process of crystal calibration?

- Crystal calibration involves accurately measuring and adjusting the frequency of a crystal oscillator to ensure it operates at the desired frequency within specified tolerances.

- Steps include:

- Selecting a suitable crystal oscillator for the application.

- Connecting the oscillator to a frequency counter for precise frequency measurement.

- Adjusting the oscillator’s load capacitance or other parameters using external components (e.g., capacitors, resistors) to bring the frequency within the desired range.

- Verifying the frequency stability and accuracy over temperature and environmental conditions.

- Documenting the calibration data and providing traceability to standards.

2. What are the different types of crystal cuts used in oscillators?

AT-Cut Crystals

- Commonly used in low-frequency applications (below 3 MHz)

- Provide good temperature stability and low aging rates

BT-Cut Crystals

- Higher frequency range (up to 30 MHz)

- Lower temperature stability and higher aging rates

- Offer lower cost and smaller size

SC-Cut Crystals

- Suitable for high-frequency applications (above 30 MHz)

- Excellent temperature stability and low aging rates

- Higher cost and larger size

3. What factors affect the accuracy and stability of crystal oscillators?

- Temperature variations: Crystals exhibit temperature-dependent frequency shifts. Proper temperature compensation or controlled environments are crucial.

- Aging: Crystals gradually change frequency over time. Aging rates vary depending on the cut, manufacturing process, and storage conditions.

- Load capacitance: External components connected to the oscillator can affect its frequency. Proper load matching is essential.

- Environmental factors: Humidity, vibration, and shock can impact oscillator stability and accuracy.

4. How do you troubleshoot a crystal oscillator that is not functioning properly?

- Verify the power supply and ensure it meets specifications.

- Measure the output frequency using a frequency counter and compare it to the expected value.

- Adjust load capacitance if necessary to bring the frequency within the desired range.

- Check for any loose connections or damaged components in the oscillator circuit.

- If the issue persists, consider replacing the crystal or consulting with a manufacturer for further troubleshooting.

5. What are the different methods used for compensating temperature effects in crystal oscillators?

Oven-Controlled Crystals (OCXO)

- Maintain the crystal at a constant temperature (e.g., 70°C) using a heater and temperature sensor.

- Provide high accuracy and stability, but can be bulky and expensive.

Temperature-Compensated Crystals (TCC)

- Incorporate additional elements into the crystal structure that exhibit opposite temperature coefficients.

- Reduce temperature drift but not as effective as OCXOs.

External Compensation Circuits

- Use external components (e.g., thermistors, resistors) to modify the oscillator’s load capacitance based on temperature.

- Less expensive than OCXOs but offer lower accuracy.

6. What are the advantages of using surface-mount crystal oscillators (SMOs)?

- Compact size and low profile, suitable for space-constrained applications.

- Lower cost compared to through-hole oscillators.

- Improved reliability due to reduced solder joints and mechanical stress.

- Enhanced performance in high-frequency applications.

7. Explain the difference between crystal oscillators and voltage-controlled crystal oscillators (VCCOs).

- Crystal oscillators provide a fixed output frequency determined by the crystal’s resonant frequency.

- VCCOs allow the output frequency to be tuned over a range by applying a control voltage.

- VCCOs are used in applications requiring frequency modulation or phase-locked loops (PLLs).

8. How do you ensure the traceability of crystal calibration measurements?

- Use calibrated frequency counters and other test equipment with traceable certifications.

- Establish calibration procedures that comply with relevant standards (e.g., ISO 17025).

- Maintain records of calibration data, including equipment used and calibration intervals.

- Provide documentation that links calibration measurements to specific crystal oscillators.

9. What are the safety precautions to consider when handling and calibrating crystals?

- Wear appropriate personal protective equipment (e.g., ESD wrist strap, safety glasses).

- Handle crystals carefully to avoid damage or contamination.

- Use proper tools and techniques to manipulate crystals.

- Follow established safety protocols and guidelines for working with electronic components.

10. Describe your experience in using simulation software for crystal oscillator design and analysis.

- Explain the simulation software used (e.g., Simulink, Cadence).

- Discuss the capabilities and limitations of the software for oscillator design.

- Provide examples of how you have used the software to optimize oscillator performance.

- Highlight any unique features or methodologies you have developed in this area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crystal Calibrator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crystal Calibrator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Crystal Calibrators play a crucial role in ensuring the accuracy and precision of scientific instruments used in various fields such as healthcare, research, and manufacturing. Their primary responsibilities involve the calibration, maintenance, and repair of crystal oscillators, which are essential components in electronic devices.

1. Calibration and Adjustment

Calibrate and adjust crystal oscillators to meet specified frequency, stability, and accuracy requirements.

- Use specialized equipment and software to measure and analyze oscillator performance.

- Adjust oscillator parameters such as capacitance, inductance, and temperature compensation to achieve optimal performance.

2. Maintenance and Troubleshooting

Perform regular maintenance and troubleshooting to ensure the proper functioning of crystal oscillators.

- Inspect oscillators for physical damage, wear, or corrosion.

- Troubleshoot and resolve issues related to oscillator performance, stability, or failure.

3. Quality Control and Documentation

Maintain a high level of quality control and documentation to ensure the accuracy and traceability of calibration data.

- Follow established quality control procedures and specifications.

- Document all calibration and maintenance activities, including test results, adjustments made, and any irregularities encountered.

4. Technical Support and Training

Provide technical support to customers and other stakeholders regarding crystal oscillator calibration and performance.

- Answer queries and provide guidance on oscillator selection, calibration, and maintenance.

- Conduct training sessions on crystal oscillator principles and calibration techniques.

Interview Tips

Preparing thoroughly for a Crystal Calibrator interview is essential to showcase your skills, experience, and enthusiasm for the role. Here are some key tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific job requirements. Research the company’s website, LinkedIn page, and any other relevant sources.

2. Highlight Your Technical Skills

Demonstrate your in-depth knowledge of crystal oscillator calibration principles, techniques, and equipment. Provide specific examples of your experience in calibrating and troubleshooting crystal oscillators used in various applications.

3. Emphasize Quality and Accuracy

Emphasize your commitment to maintaining high levels of quality and accuracy in your work. Highlight your ability to follow established procedures and document your findings thoroughly.

4. Prepare for Problem-Solving Questions

Interviewers may ask you to describe how you would approach specific technical challenges related to crystal oscillator calibration. Prepare by recalling real-life examples where you successfully diagnosed and resolved issues.

5. Showcase Your Communication Skills

Crystal Calibrators often interact with customers and colleagues to provide technical support and training. Demonstrate your ability to communicate clearly and effectively in both written and verbal forms.

6. Demonstrate Teamwork and Collaboration

Highlight your experience working in a team environment and collaborating with others to achieve common goals. Mention specific instances where you contributed to team success.

7. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions that demonstrate your understanding of the role and the company’s industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crystal Calibrator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!