Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Crystalizer Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Crystalizer Tender so you can tailor your answers to impress potential employers.

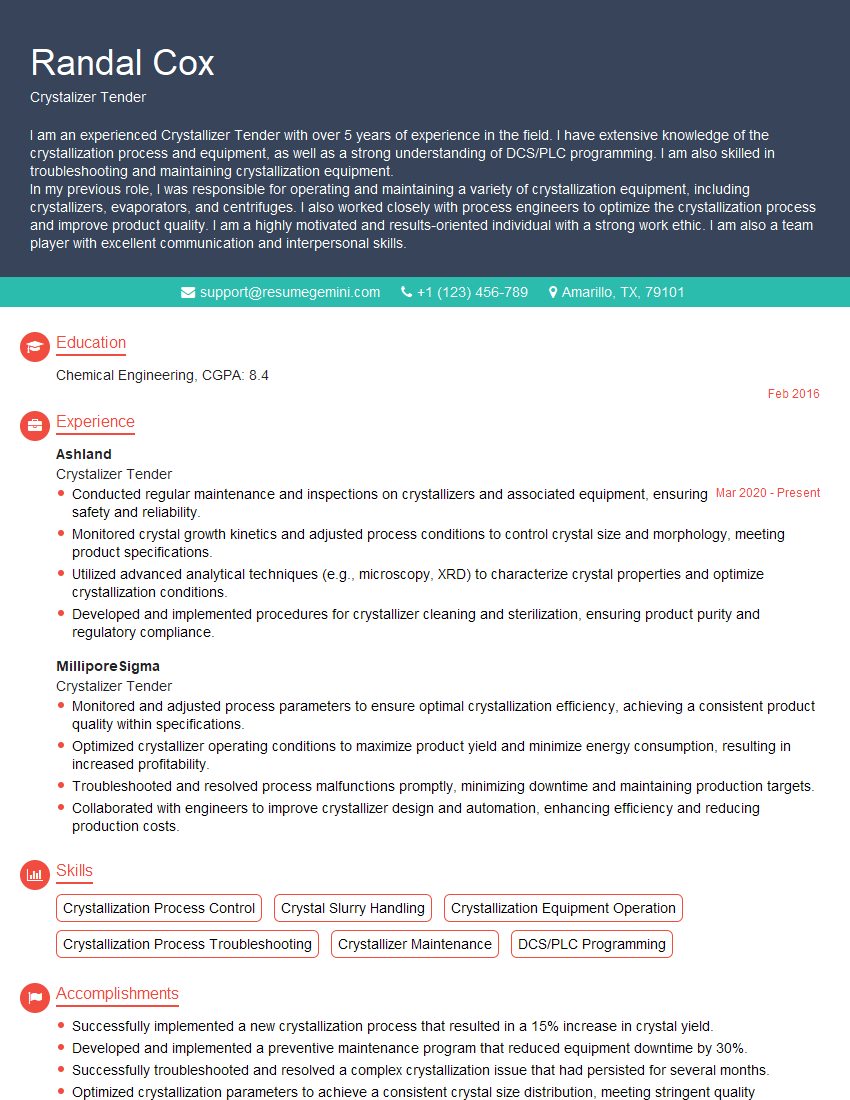

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Crystalizer Tender

1. Explain the process of crystallizer operation in a sugar mill.

The crystallizer is a key piece of equipment in a sugar mill, responsible for the growth and crystallization of sugar crystals in the sugar-bearing liquor.

The process of crystallizer operation involves the following steps:

- Preparation of the liquor: The liquor to be crystallized is first preheated and then cooled to the desired crystallization temperature.

- Seeding: The liquor is seeded with a small amount of sugar crystals, which provides a surface for the new sugar crystals to grow on.

- Crystallization: The liquor is agitated and held at a constant temperature to allow the sugar crystals to grow. The crystals will continue to grow until they reach the desired size.

- Massecuite discharge: Once the crystals have reached the desired size, the massecuite (a mixture of crystals and liquor) is discharged from the crystallizer.

2. What are the factors that affect the crystallization process?

Temperature:

- The crystallization temperature affects the size and shape of the sugar crystals.

- Higher temperatures lead to the formation of larger crystals, while lower temperatures produce smaller crystals.

Agitation:

- Agitation is used to keep the liquor in suspension and to prevent the crystals from settling out.

- The rate of agitation affects the size and shape of the crystals.

Super saturation:

- Supersaturation is the difference between the concentration of sugar in the liquor and the solubility of sugar at the crystallization temperature.

- Higher levels of supersaturation lead to faster crystallization rates and smaller crystals.

Seed size:

- The size of the seeds used to initiate crystallization affects the size of the final crystals.

- Larger seeds lead to the formation of larger crystals.

Impurities:

- Impurities in the liquor can interfere with the crystallization process and lead to the formation of smaller crystals.

- Impurities can also cause the crystals to grow in an irregular shape.

3. Describe the importance of massecuite control in the crystallization process.

Massecuite control is critical to the crystallization process because it affects the quality of the sugar crystals and the efficiency of the crystallization operation.

The following are some of the key parameters that need to be controlled in massecuite:

- Crystal size distribution: The massecuite should have a narrow crystal size distribution to ensure uniform crystal growth and prevent the formation of large crystals.

- Purity: The massecuite should have a high purity to ensure the production of high-quality sugar crystals.

- Viscosity: The massecuite should have a viscosity that is low enough to allow for proper agitation and crystal growth.

- Temperature: The massecuite should be maintained at the desired crystallization temperature to ensure optimal crystal growth.

By controlling these parameters, the crystallizer operator can optimize the crystallization process and produce high-quality sugar crystals.

4. What are the common problems encountered in crystallizer operation?

- Scaling: Scaling can occur when impurities in the liquor deposit on the surfaces of the crystallizer and heat transfer equipment.

- Fouling: Fouling can occur when organic matter in the liquor deposits on the surfaces of the crystallizer and heat transfer equipment.

- Corrosion: Corrosion can occur when the crystallizer is exposed to corrosive chemicals in the liquor.

- Mechanical problems: Mechanical problems can occur with the agitator, pumps, and other equipment used in the crystallizer.

- Process control problems: Process control problems can occur when the temperature, agitation rate, or other process parameters are not properly controlled.

5. Describe the safety procedures that must be followed when operating a crystallizer.

- Wear appropriate personal protective equipment (PPE): This includes a hard hat, safety glasses, gloves, and a lab coat.

- Be aware of the location of emergency exits and fire extinguishers: In case of an emergency, it is important to be able to evacuate the area quickly and safely.

- Do not enter the crystallizer unless it is properly locked out and tagged out: This is to prevent accidental injury from moving parts or hot surfaces.

- Be aware of the potential for steam leaks: Steam leaks can cause burns and other injuries.

- Follow all operating procedures and instructions: This is to ensure that the crystallizer is operated safely and efficiently.

6. What is the role of a crystallizer tender in a sugar mill?

- Operate the crystallizer: This includes starting and stopping the crystallizer, controlling the temperature, agitation rate, and other process parameters.

- Monitor the crystallizer: This includes monitoring the crystal size distribution, purity, viscosity, and temperature of the massecuite.

- Troubleshoot and resolve problems: This includes identifying and resolving problems with the crystallizer, such as scaling, fouling, corrosion, and mechanical problems.

- Maintain the crystallizer: This includes cleaning and inspecting the crystallizer, and replacing worn or damaged parts.

- Follow safety procedures: This includes wearing appropriate PPE, being aware of emergency exits and fire extinguishers, and following all operating procedures and instructions.

7. What qualifications are required to be a crystallizer tender?

- High school diploma or equivalent: A high school diploma or equivalent is typically required to be a crystallizer tender.

- Experience in the sugar industry: Experience in the sugar industry is preferred, but not always required.

- Knowledge of crystallizer operation: Knowledge of crystallizer operation is essential to be a crystallizer tender.

- Ability to troubleshoot and resolve problems: The ability to troubleshoot and resolve problems is essential to be a crystallizer tender.

- Strong communication skills: Strong communication skills are essential to be a crystallizer tender.

8. What are the career opportunities for a crystallizer tender?

- Crystallizer operator: A crystallizer tender can advance to a crystallizer operator position.

- Sugar boiler: A crystallizer tender can advance to a sugar boiler position.

- Production supervisor: A crystallizer tender can advance to a production supervisor position.

- Plant manager: A crystallizer tender can advance to a plant manager position.

9. What is the typical salary for a crystallizer tender?

The typical salary for a crystallizer tender is between $25,000 and $50,000 per year.

10. What is the job outlook for crystallizer tenders?

The job outlook for crystallizer tenders is expected to be stable over the next few years.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Crystalizer Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Crystalizer Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Crystallizer Tender, you will undertake a range of vital responsibilities within a chemical processing environment, ensuring the efficient operation and maintenance of crystallizer equipment and processes.

1. Operating Crystallizer Equipment

You will be responsible for the safe and efficient operation of crystallizer equipment, including vacuum filters and pumps. This involves monitoring and adjusting process parameters, such as temperature, pressure, and flow rates, to optimize crystallization outcomes.

- Operate crystallizers to produce crystals of desired size, shape, and purity

- Monitor and adjust process parameters to ensure optimal crystallization conditions

2. Maintaining Equipment

Regular maintenance is crucial to ensure the smooth running of the crystallizer equipment. You will perform routine maintenance tasks, such as cleaning, lubricating, and replacing worn parts, to maintain optimal performance.

- Perform regular maintenance and repairs on crystallizers and associated equipment

- Inspect and clean equipment to ensure proper operation

3. Monitoring Process Quality

You will continuously monitor the crystallization process to ensure that the resulting crystals meet the required quality standards. This involves sampling and analyzing crystals, and making adjustments to the process parameters as needed.

- Monitor and control the crystallization process to ensure production of crystals with desired properties

- Conduct quality control tests on crystals to ensure they meet specifications

4. Troubleshooting and Problem-Solving

In the event of any problems with the crystallizer equipment or process, you will be responsible for troubleshooting and resolving the issue. This may involve diagnosing the root cause of the problem, making necessary repairs, and implementing corrective actions to prevent future occurrences.

- Troubleshoot and resolve problems with crystallizers and associated equipment

- Identify and correct process deviations to maintain optimal operating conditions

Interview Tips

To ace your interview for a Crystallizer Tender position, here are some valuable preparation tips and interview hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and the industry they operate in. This will demonstrate your genuine interest in the role and help you understand the context of the position.

- Visit the company’s website and read industry-related news

- Learn about the specific crystallization processes used in the company

2. Practice Your Technical Skills

Be confident in your technical abilities related to crystallizer operation and maintenance. Review your knowledge of crystallizer types, process parameters, and troubleshooting techniques.

- Explain the working principles of different types of crystallizers

- Describe common process parameters and their impact on crystallization outcomes

3. Prepare for Common Interview Questions

Research common interview questions specific to the Crystallizer Tender role. Practice answering questions about your experience, technical knowledge, and problem-solving abilities.

- Tell me about your experience in operating and maintaining crystallizers.

- Describe a challenging situation you faced while working as a Crystallizer Tender and how you resolved it.

4. Highlight Your Safety and Quality Awareness

Emphasize your commitment to safety and quality in the workplace. Showcase your understanding of safety protocols, quality control procedures, and industry regulations.

- Describe your experience with safety procedures related to crystallizer operation

- Explain how you ensure the quality of crystals produced by the crystallizer

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive at the interview venue on time to demonstrate respect for the interviewer and the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Crystalizer Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!