Are you gearing up for a career in Cuff Sewer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cuff Sewer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

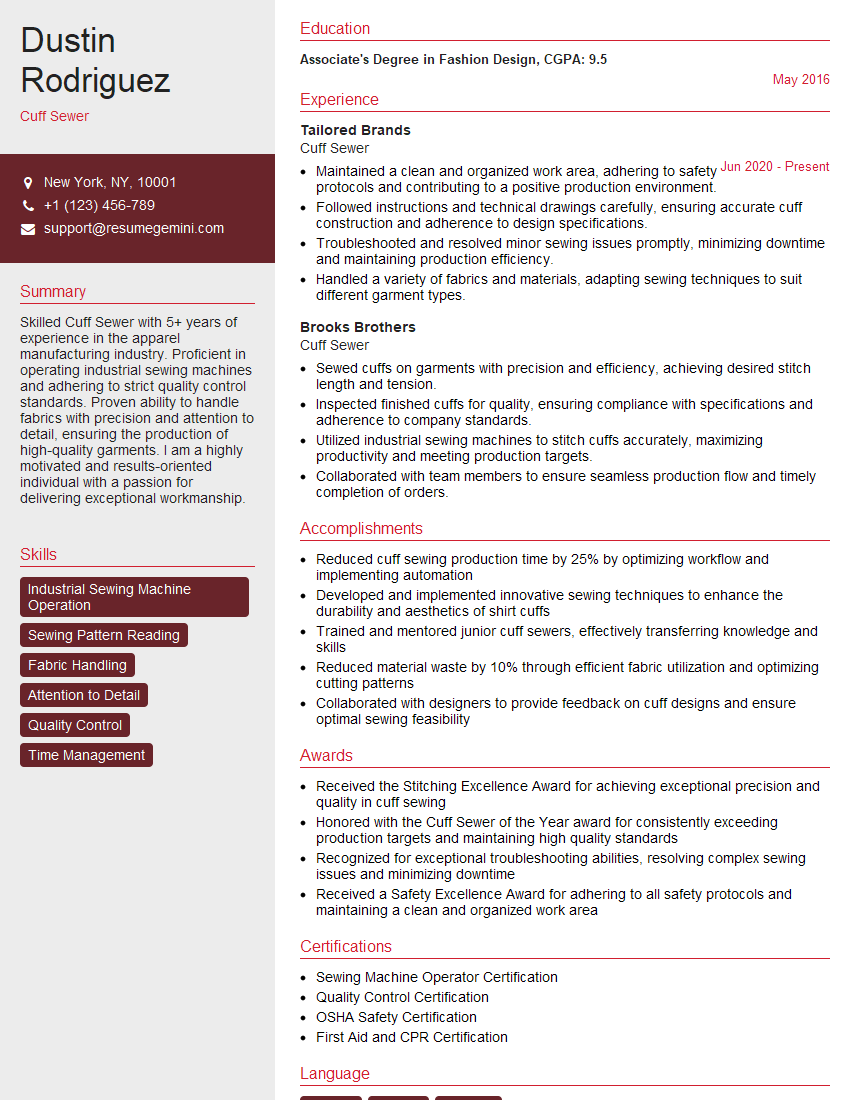

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cuff Sewer

1. What are the primary materials used in cuff finishing?

The primary materials used in cuff finishing include:

- Fusing – This is a material used to bond the cuff lining to the cuff fabric.

- Interfacing – This material is used to give the cuff structure and support.

- Cuff lining – This material is used to finish the inside of the cuff.

- Cuff fabric – This is the outer material of the cuff.

2. Explain the process of bias cutting for cuffs.

Bias cutting involves cutting fabric at a 45-degree angle to the grain line.

Advantages of bias cutting for cuffs:

- Improved drape and flexibility.

- Reduced fraying and seam puckering.

- Enhanced comfort and fit.

Steps for bias cutting:

- Lay the fabric flat and identify the grain line.

- Use a ruler or measuring tape to mark a 45-degree angle from the grain line.

- Fold the fabric along the marked line and secure it with pins.

- Cut along the folded line to obtain the bias-cut fabric.

3. What are the different types of cuff construction methods?

- French cuff: A classic and elegant style, featuring a double layer of fabric folded back on itself.

- Barrel cuff: A simple and versatile option, with a single layer of fabric folded over and stitched.

- Convertible cuff: A versatile style that can be worn folded or unfolded, offering two different looks.

- Mitred cuff: A tailored and sophisticated style, featuring a 45-degree angled seam at the corner.

- Button cuff: A functional and convenient style, featuring buttons or snaps for closure.

4. What factors should be considered when selecting the appropriate cuff design for a garment?

- Garment style: The cuff design should complement the overall style of the garment.

- Fabric choice: The weight and drape of the fabric will influence the choice of cuff construction.

- Intended use: The purpose of the garment (e.g., formal, casual, workwear) will impact the cuff design.

- Personal preference: The wearer’s personal style and comfort preferences should also be taken into account.

5. What are the common issues encountered during cuff finishing and how can they be resolved?

- Puckering or wrinkles: Ensure proper pressing and use steam to smooth out wrinkles. Adjust the tension of the sewing machine or hand-stitch if necessary.

- Uneven stitching: Calibrate the sewing machine regularly and use a consistent stitch length. Practice maintaining a steady hand while sewing.

- Fraying edges: Finish the edges of the cuff fabric using a serger, pinking shears, or a fray-check solution.

- Improper fit: Measure the circumference of the wrist and compare it to the cuff’s dimensions. Adjust the cuff’s size or use a different cuff design if needed.

6. Describe the role of interfacing in cuff finishing.

- Provides structure and support to the cuff.

- Prevents the cuff from becoming limp or sagging.

- Enhances the overall appearance and durability of the cuff.

- Can be used in various weights and types, depending on the desired stiffness or drape.

7. What are the different methods for attaching a cuff to a sleeve?

- Set-in cuff: The cuff is sewn into the armhole seam, creating a smooth and tailored look.

- Attached cuff: The cuff is sewn directly onto the end of the sleeve, providing a more casual and relaxed style.

- Convertible cuff: The cuff can be attached or detached using buttons or snaps, offering versatility.

- Elastic cuff: The cuff is made of elastic material and is sewn or gathered onto the sleeve, providing a snug and comfortable fit.

8. What are the key quality control measures for cuff finishing?

- Inspect the cuff for even stitching, proper seam allowances, and no loose threads.

- Check the cuff’s dimensions to ensure they match the garment’s specifications.

- Test the cuff’s functionality, such as buttonholes or snaps, to ensure they work properly.

- Examine the cuff’s appearance for any defects, such as puckering, wrinkles, or fraying.

9. How do you stay updated with the latest trends and advancements in cuff finishing techniques?

- Attend industry workshops and seminars.

- Read trade publications and online resources.

- Connect with other cuff finishers and designers.

- Experiment with new materials and techniques.

10. Can you provide an example of a challenging cuff finishing project you have worked on and how you overcame the challenges?

Provide a specific example of a complex or challenging cuff finishing project you have completed, highlighting the technical skills and problem-solving abilities you employed to achieve a successful outcome.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cuff Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cuff Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cuff Sewer is accountable for performing a range of essential operations in the production of cuffs, ensuring the consistent output of high-quality products. Key job responsibilities encompass:

1. Cuff Sewing

Playing a pivotal role in the production process, the Cuff Sewer meticulously follows established sewing techniques to stitch cuffs accurately and efficiently. They operate specialized sewing machines to join various fabric pieces, ensuring precise and durable seams. The quality of their work directly affects the aesthetics and functionality of the finished product.

2. Material Handling

Cuff Sewers are responsible for handling and managing fabrics and other materials with utmost care throughout the sewing process. They inspect incoming materials, ensuring they meet required specifications and standards. They also handle finished cuffs, packaging them properly for storage and distribution.

3. Equipment Maintenance

Maintaining a clean and functional work environment is crucial for efficient production. Cuff Sewers regularly clean and maintain their sewing machines and other equipment, ensuring optimal performance and longevity. They also report any issues or malfunctions promptly to ensure timely repairs and minimize downtime.

4. Quality Control

Cuff Sewers play a vital role in maintaining high quality standards in the production process. They inspect cuffs throughout the sewing process, carefully checking for any defects or inconsistencies. They also collaborate with quality control personnel to identify potential issues and implement preventive measures.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some valuable tips to help you ace your Cuff Sewer interview

1. Research the Company and Position

Before the interview, take ample time to research the company you are applying to and the specific Cuff Sewer position. Understand their products, services, and company culture. This knowledge will enable you to align your skills and experience with the company’s requirements and demonstrate your enthusiasm.

2. Practice Your Skills

Ensure you are confident in your cuff sewing abilities before the interview. Practice sewing different types of cuffs using various fabrics to refresh your skills and enhance your precision. Being able to showcase your proficiency during the interview can greatly impress the hiring manager.

3. Prepare for Technical Questions

Interviewers often ask technical questions to evaluate your understanding of cuff sewing techniques and equipment. Prepare for questions related to sewing machine operation, fabric types, and quality control procedures. Having a solid grasp of these concepts will demonstrate your competence and professionalism.

4. Highlight Your Experience

During the interview, emphasize your experience and skills that are relevant to the Cuff Sewer role. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency and the positive impact of your work. Share instances where you improved production efficiency or maintained high-quality standards.

5. Ask Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare insightful questions about the company’s production processes, growth plans, or any specific aspects of the Cuff Sewer role. This engagement indicates your curiosity and genuine desire to learn more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cuff Sewer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!