Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cupola Liner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

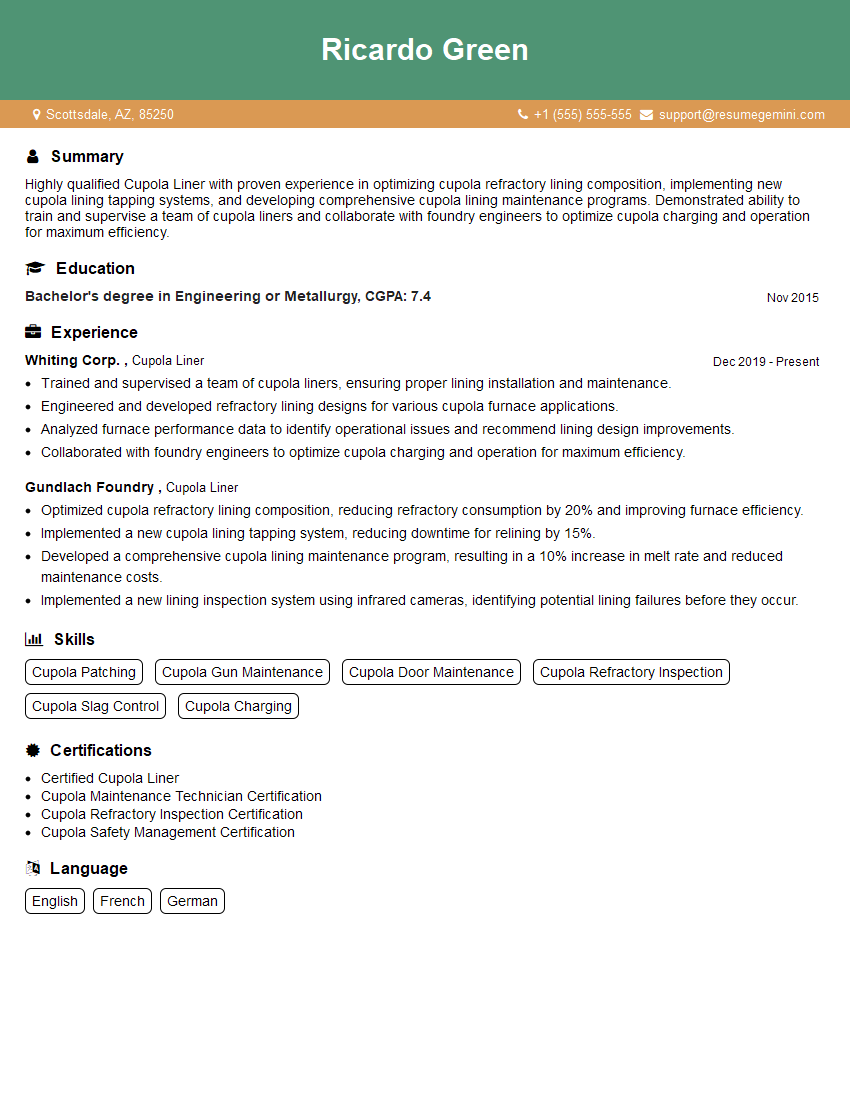

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Liner

1. Explain the process of lining a cupola with refractory material?

The process of lining a cupola with refractory material involves several steps:

- Select the appropriate refractory material: Choose a material that can withstand the high temperatures and corrosive conditions inside the cupola. Common materials include fireclay, silica, magnesia, and alumina.

- Prepare the cupola: Clean and inspect the cupola to ensure it is free from any debris or damage. Use a template or chalk line to mark the location of the refractory lining.

- Apply a bonding agent: Apply a thin layer of bonding agent, such as clay slip or mortar, to the interior of the cupola.

- Install the refractory bricks: Start by laying the firebricks in the bottom of the cupola, ensuring they are tightly fitted and level. Gradually build up the lining, alternating between courses of firebricks and refractory mortar.

- Cure the lining: Allow the lining to cure properly by gradually heating it to the operating temperature. This process helps dry out the mortar and strengthen the lining.

2. What are the factors that affect the life of a cupola lining?

Operating Conditions:

- Iron composition

- Melting rate

- Charge materials

Material Properties:

- Refractory type

- Insulation

- Chemical composition

Maintenance Practices:

- Lining thickness

- Patching and repair

- Slag control

3. How do you troubleshoot and repair a damaged cupola lining?

Troubleshooting and repairing a damaged cupola lining involves the following steps:

- Identify the damage: Inspect the lining for cracks, holes, or other signs of damage. Use a flashlight or inspection camera to examine hard-to-reach areas.

- Determine the cause: Analyze the operating conditions, material properties, and maintenance practices to identify potential causes of the damage.

- Prepare the lining: Clean the damaged area and remove any loose material. Grind or chisel out damaged sections to create a clean surface.

- Apply new refractory material: Use a suitable refractory material to patch or replace the damaged section. Ensure proper bonding and curing to restore the lining’s integrity.

- Monitor and maintain: Regularly inspect the repaired lining and make adjustments as necessary to prevent further damage.

4. Explain the importance of proper slag control in cupola operation?

Proper slag control is crucial in cupola operation for the following reasons:

- Prevents damage to the lining: Slag can accumulate on the cupola lining and cause erosion or chemical attack, leading to premature failure.

- Maintains iron quality: Slag can contaminate the molten iron, affecting its composition and properties.

- Optimizes melting efficiency: High slag levels can increase the viscosity of the molten iron, making it difficult to tap and reducing the melting rate.

- Ensures safety: Slag accumulation can block tap holes or cause explosions if not properly controlled.

5. What are the different types of charge materials used in cupola operation?

Various charge materials are used in cupola operation, including:

- Iron: Scrap iron, pig iron, steel, and ferroalloys provide the primary source of iron for melting.

- Coke: Coke serves as the fuel for the cupola, providing heat and reducing the iron ore to molten iron.

- Flux: Fluxing agents, such as limestone and fluorspar, help remove impurities from the molten iron and form slag.

- Additives: Materials like silicon carbide, graphite, and manganese can be added to adjust the iron’s composition and properties.

6. How do you calculate the coke ratio for a cupola?

The coke ratio is the ratio of coke to iron in the cupola charge. It is typically expressed as a percentage and can be calculated using the following formula:

Coke Ratio = (Weight of Coke / Weight of Iron) x 100%

The coke ratio varies depending on factors such as the type of iron, coke quality, and desired melting rate. A typical coke ratio ranges from 7% to 15%.

7. Explain the principle of cupola melting?

The principle of cupola melting involves the following steps:

- Charging: Charge materials (iron, coke, flux) are loaded into the cupola.

- Combustion: Air is blown into the cupola through tuyeres, causing the coke to burn and generate heat.

- Melting: The heat from the combustion melts the iron, which trickles down through the coke bed.

- Tapping: The molten iron is collected in a ladle through a tap hole at the bottom of the cupola.

- Slag formation: Impurities in the iron and coke react with the flux to form slag, which floats on top of the molten iron.

8. What factors influence the melting rate in a cupola?

The melting rate in a cupola is influenced by several factors:

- Coke ratio: A higher coke ratio increases the melting rate.

- Blast volume and pressure: Higher air volume and pressure increase the combustion rate, leading to a faster melting rate.

- Cupola size: Larger cupolas can accommodate more charge materials, resulting in a higher melting rate.

- Charge materials: The size, shape, and composition of the charge materials can affect the packing density and melting rate.

- Cupola design and operating practices: Proper lining maintenance, efficient charging, and slag control contribute to an optimal melting rate.

9. How do you optimize cupola operation for energy efficiency?

Optimizing cupola operation for energy efficiency involves:

- Use of high-quality coke: High-quality coke with low ash content and good combustion properties improves energy efficiency.

- Proper blast control: Optimizing the air volume and pressure ensures efficient combustion and heat utilization.

- Cupola lining maintenance: A well-maintained lining prevents heat loss through gaps or cracks.

- Charge material preparation: Sized and graded charge materials improve packing density, reducing voids and heat loss.

- Utilization of waste heat: Capturing waste heat from the exhaust gases can be used to preheat the blast air or generate steam.

10. Describe the safety precautions to be observed when working with a cupola?

Working with a cupola requires strict adherence to safety precautions:

- Wear appropriate PPE: Heat-resistant clothing, gloves, eye protection, and respiratory protection are essential.

- Maintain a clean and organized work area: Keep the cupola and surrounding area free from clutter and tripping hazards.

- Operate the cupola according to established procedures: Follow all safety protocols and guidelines for charging, tapping, and maintenance.

- Be aware of potential hazards: Identify and mitigate risks such as molten metal splashes, slag spills, and gas emissions.

- Regularly inspect and maintain the cupola: Conduct regular inspections and maintenance to ensure the equipment is in good working condition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Liner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Liner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cupola Liners are responsible for the proper operation and maintenance of cupola furnaces used in the production of ferrous metals. They play a crucial role in ensuring the efficient and safe operation of these furnaces.

1. Furnace Preparation

Preparing the cupola furnace for operation by lining it with refractory materials to create the furnace bed.

- Selecting and installing refractory bricks and linings to meet specific furnace requirements.

- Ensuring proper fit and bonding of refractory materials to prevent leaks and maintain structural integrity.

2. Furnace Operation

Operating the cupola furnace to produce molten metal by charging it with raw materials.

- Loading the furnace with a blend of coke, iron ore, limestone, and other materials.

- Monitoring and adjusting furnace temperature and airflow to optimize melting efficiency.

3. Furnace Maintenance

Inspecting, cleaning, and repairing the cupola furnace to ensure its longevity and safe operation.

- Identifying and replacing worn or damaged refractory linings to prevent furnace failures.

- Maintaining proper insulation to minimize heat loss and improve energy efficiency.

4. Safety Compliance

Ensuring compliance with safety regulations and procedures to minimize risks and protect workers.

- Adhering to established safety protocols for furnace operation and maintenance.

- Wearing appropriate personal protective equipment (PPE) and ensuring the safety of others in the work area.

Interview Tips

To prepare for an interview for a Cupola Liner position:

1. Research the Company and Industry

Learn about the company’s history, products, and industry trends. This shows that you are interested in the role and have taken the time to understand the context.

- Visit the company’s website and read industry publications.

- Attend industry events and network with professionals.

2. Practice Common Interview Questions

Prepare answers to common interview questions such as:

- Tell me about yourself and your experience in cupola lining.

- Why are you interested in this role at our company?

- Describe a challenging situation you faced in a previous role and how you overcame it.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and cover letter. Use specific examples to demonstrate your abilities.

- Highlight your knowledge of cupola furnace operation, maintenance, and safety procedures.

- Quantify your accomplishments whenever possible, using numbers and metrics.

4. Be Professional and Confident

Dress appropriately, arrive on time, and be respectful throughout the interview. Maintain eye contact and speak clearly and confidently.

- Practice your answers to interview questions in front of a mirror or with a friend.

- Prepare questions to ask the interviewer, demonstrating your interest and engagement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cupola Liner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cupola Liner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.