Feeling lost in a sea of interview questions? Landed that dream interview for Cupola Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cupola Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

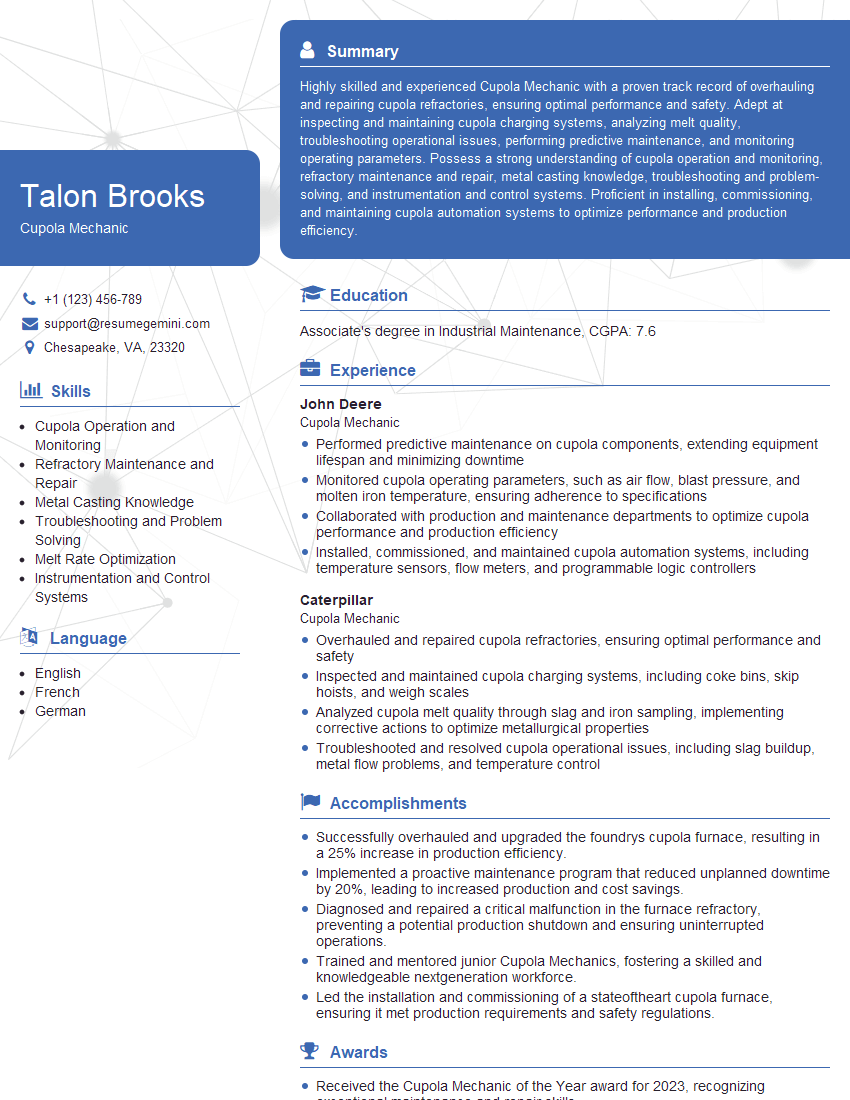

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Mechanic

1. What are the key responsibilities of a Cupola Mechanic?

The key responsibilities of a Cupola Mechanic include:

- Maintaining and repairing cupolas, hot blast stoves, and other equipment.

- Performing routine inspections and preventive maintenance.

- Troubleshooting and repairing mechanical and electrical problems.

- Installing new equipment and modifying existing equipment.

- Working with other trades and departments to ensure smooth operation of the plant.

2. What are the qualifications and experience required to be a Cupola Mechanic?

Education and Training

- High school diploma or equivalent

- Trade school or apprenticeship program in industrial mechanics or a related field

Experience

- 2-5 years of experience working as a Cupola Mechanic or in a related field

3. What are the different types of cupolas?

There are several types of cupolas, including:

- Hot blast cupolas

- Cold blast cupolas

- Acid cupolas

- Basic cupolas

- Duplex cupolas

4. What are the advantages and disadvantages of using a cupola?

Advantages

- High melting capacity

- Relatively low capital cost

- Can handle a wide variety of scrap materials

Disadvantages

- High operating costs

- Poor environmental performance

- Limited ability to control metal composition

5. What are the safety precautions that must be taken when working with a cupola?

When working with a cupola, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and earplugs.

- Be aware of the hazards of hot metal and molten slag.

- Keep the work area clean and free of debris.

- Follow all safety procedures and guidelines.

6. What are the most common problems that can occur with a cupola?

The most common problems that can occur with a cupola include:

- Clogged tuyeres

- Bridging of the charge

- Breakouts of molten metal

- Mechanical failures

7. How do you troubleshoot and repair a clogged tuyere?

To troubleshoot and repair a clogged tuyere, you should:

- Inspect the tuyere for any visible obstructions.

- Use a rod or wire to clear any obstructions from the tuyere.

- If the tuyere is still clogged, you may need to remove it from the cupola and clean it.

8. How do you prevent bridging of the charge?

To prevent bridging of the charge, you should:

- Use a properly sized charge.

- Charge the cupola in layers, alternating between layers of coke and layers of metal.

- Use a flux to help prevent the formation of bridges.

9. What are the signs of a breakout of molten metal?

The signs of a breakout of molten metal include:

- A sudden increase in the temperature of the cupola shell

- A bright orange glow coming from the cupola

- A loud noise

10. How do you respond to a breakout of molten metal?

If a breakout of molten metal occurs, you should:

- Immediately shut off the blast

- Close the tap hole

- Call for help

- Evacuate the area

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cupola Mechanic holds the critical responsibility of maintaining, repairing, and troubleshooting cupolas, their components, and associated equipment.

1. Equipment Upkeep

Ensures optimal performance and longevity of cupolas by performing:

- Regular inspections, calibrations, and adjustments

- Preventive maintenance tasks to address potential issues

- Overhauls and refurbishments of cupolas and equipment

2. Troubleshooting and Repairs

Effectively identifies and resolves operational issues and malfunctions:

- Conducts diagnostics, inspections, and performance analyses

- Replaces or repairs faulty components, including electrical systems, sensors, and actuators

- Calibrates and adjusts equipment to optimize performance

3. Compliance and Safety

Prioritizes safety and adheres to regulatory standards:

- Conducts risk assessments and implements safety measures

- Follows maintenance protocols and industry best practices

- Complies with environmental regulations and ensures proper waste disposal

4. Communication and Collaboration

Effectively communicates with colleagues, supervisors, and vendors:

- Provides technical insights and recommendations

- Participates in maintenance planning and scheduling discussions

- Coordinates with vendors and suppliers for parts and services

Interview Tips

To effectively prepare for your Cupola Mechanic interview, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s operations, market position, and industry trends.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and career goals.

3. Highlight Relevant Experiences

Focus on highlighting experiences that demonstrate your technical abilities, problem-solving skills, and commitment to safety.

4. Quantify Accomplishments

When describing your accomplishments, use specific numbers and metrics to showcase the impact of your work.

5. Be Prepared with Questions

Asking thoughtful questions during the interview shows your engagement and interest in the role and company.

Here are sample interview questions for Cupola Mechanics:

- Describe your experience in troubleshooting and repairing cupolas.

- How do you ensure compliance with safety regulations and maintenance protocols?

- Provide an example of a complex repair or maintenance project you successfully completed.

- How do you handle situations where critical equipment needs immediate attention?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cupola Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.