Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cupola Melter Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cupola Melter Helper so you can tailor your answers to impress potential employers.

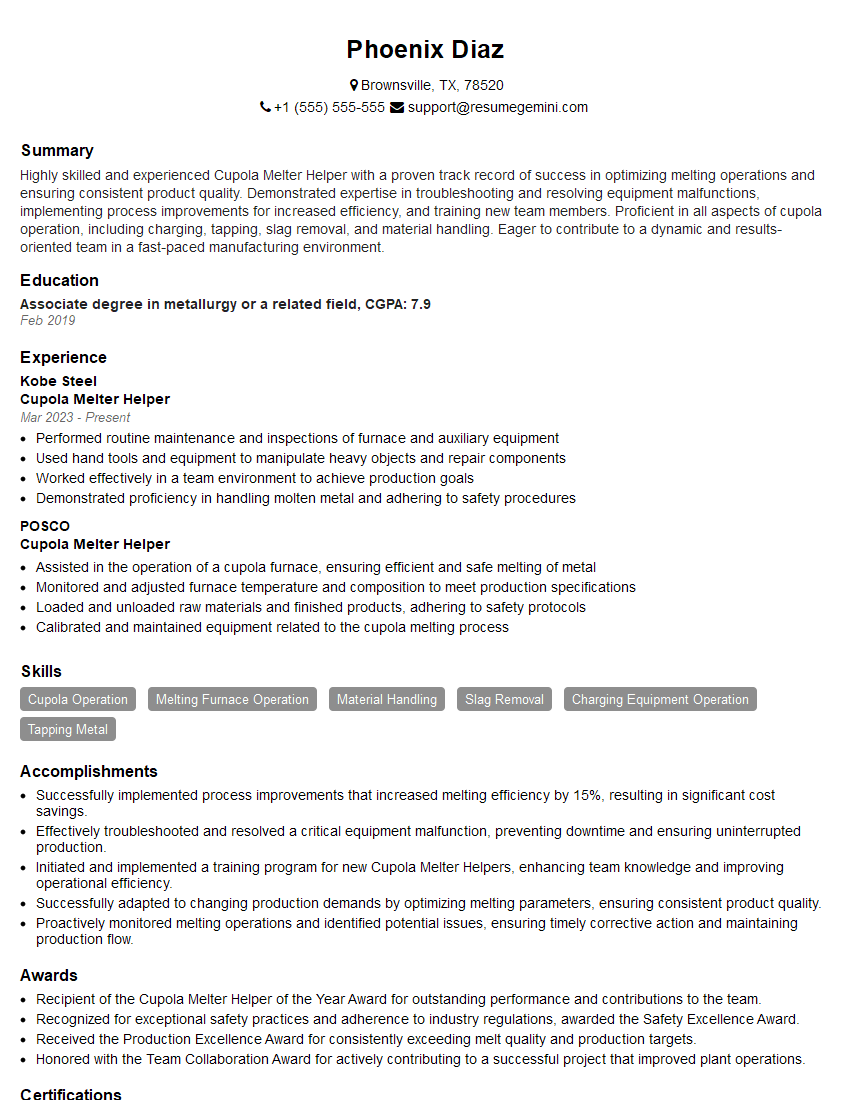

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Melter Helper

1. Explain the process of charging the cupola furnace?

- Gather the necessary materials, including coke, iron, steel, and limestone.

- Load the materials into the cupola furnace through the charging door.

- Distribute the materials evenly throughout the furnace to ensure proper melting.

- Close the charging door and seal it tightly.

- Start the melting process by igniting the coke at the bottom of the furnace.

2. How do you monitor and control the temperature of the molten metal in the cupola furnace?

Using pyrometer

- Insert the pyrometer into the molten metal through the taphole.

- Read the temperature on the pyrometer’s display.

- Adjust the air blast and fuel flow to maintain the desired temperature.

Using Optical Thermometer

- Point the optical thermometer at the molten metal stream.

- Read the temperature on the thermometer’s display.

- Adjust the air blast and fuel flow to maintain the desired temperature.

3. Describe the procedure for tapping the molten metal from the cupola furnace?

- Prepare the tapping hole by cleaning and removing any slag or debris.

- Open the tapping hole by breaking through the clay seal with a tapping bar.

- Control the flow of molten metal by adjusting the tapping hole size.

- Direct the molten metal into the ladle or other receiving vessel.

- Close the tapping hole once the desired amount of metal has been tapped.

4. How do you calculate the amount of coke required for the cupola operation?

- Determine the weight of the metal charge.

- Calculate the coke ratio based on the type of metal being melted.

- Multiply the metal charge weight by the coke ratio to get the required coke weight.

- Adjust the coke weight based on factors such as furnace size, metal composition, and desired melting rate.

5. What are the key safety precautions to be observed when operating a cupola furnace?

- Wear appropriate personal protective equipment (PPE), including heat-resistant clothing, gloves, and eye protection.

- Maintain a clean and organized work area around the furnace.

- Follow proper charging and tapping procedures to prevent accidents.

- Be aware of the potential hazards, such as hot metal, slag, and sparks.

- Have emergency response plans in place in case of an accident.

6. Describe the role of slag in the cupola furnace operation?

- Protects the furnace lining from erosion.

- Absorbs impurities from the molten metal.

- Helps regulate the temperature of the molten metal.

- Improves the fluidity and castability of the molten metal.

7. What are the common troubleshooting techniques for cupola furnace operation?

- Cold blast: Adjust the air blast volume or pressure.

- Hot blast: Check the preheater and adjust the temperature.

- Bridging: Use a poking bar to break up the bridge.

- Slag problems: Adjust the flux or slag additives.

- Metal quality issues: Check the raw materials, furnace conditions, and tapping practices.

8. How do you maintain the refractory lining of the cupola furnace?

- Inspect the lining regularly for cracks, erosion, or damage.

- Repair or replace damaged sections of the lining promptly.

- Use proper charging and tapping techniques to minimize wear and tear on the lining.

- Keep the furnace clean and free of debris that could damage the lining.

9. What are the environmental considerations for operating a cupola furnace?

- Control emissions of particulate matter, sulfur dioxide, and other pollutants.

- Dispose of slag and other waste materials properly.

- Minimize energy consumption and reduce greenhouse gas emissions.

- Comply with all applicable environmental regulations.

10. Describe the role of automation in modern cupola furnace operations?

- Automates charging, tapping, and other processes.

- Improves efficiency and productivity.

- Enhances safety by reducing human exposure to hazards.

- Provides real-time data monitoring and control.

- Optimizes furnace performance and reduces operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Melter Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Melter Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cupola Melter Helper plays a crucial role in the production and management of molten metals within a foundry or manufacturing setting.

1. Preparation and Operation

The helper assists in preparing and operating the cupola furnace, ensuring it runs efficiently and safely. This includes tasks such as:

- Loading raw materials, including scrap metal, coke, and limestone, into the furnace

- Monitoring and adjusting the furnace’s temperature and airflow to achieve optimal melting conditions

2. Metal Tapping and Transport

The helper assists in tapping the molten metal from the furnace at the appropriate time and transporting it to designated areas:

- Skimming impurities from the molten metal to ensure its quality

- Using appropriate tools and equipment to transfer molten metal safely and efficiently

3. Slag Removal and Maintenance

The helper is responsible for removing slag, a byproduct of the melting process, from the furnace and maintaining the equipment:

- Clearing away slag accumulations to prevent furnace damage and ensure efficient operation

- Performing regular maintenance tasks on the furnace, such as cleaning, inspecting, and lubricating

4. Safety and Environmental Compliance

The helper must prioritize safety and adhere to environmental regulations:

- Wearing appropriate safety gear and following established safety protocols

- Monitoring emissions and ensuring compliance with environmental standards

Interview Tips

To ace the interview for a Cupola Melter Helper position, candidates should prepare thoroughly and showcase their relevant skills and experience.

1. Research the Company and Industry

Understand the company’s history, products, and industry trends to demonstrate your interest and knowledge of the field.

- Visit the company website and social media pages

- Research industry publications and news to stay informed

2. Highlight Relevant Skills and Experience

Emphasize your experience in foundry operations, metalworking, or a related field. Quantify your accomplishments using specific metrics whenever possible.

- Describe your involvement in preparing, operating, and maintaining cupola furnaces

- Showcase your knowledge of safety protocols and environmental regulations

3. Prepare for Technical Questions

Expect questions about the cupola melting process, slag removal, and metal handling. Brush up on your technical knowledge and be ready to explain complex concepts clearly.

- Review the principles of cupola melting and the role of different materials

- Practice describing your problem-solving and troubleshooting techniques

4. Emphasize Safety and Teamwork

Safety is paramount in this role. Highlight your commitment to following safety procedures and working effectively as part of a team.

- Share examples of your safety practices and risk assessments

- Describe your experience in collaborating with colleagues and supervisors

5. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest. Prepare questions about the company’s operations, the role’s responsibilities, and potential opportunities for growth.

- Inquire about the company’s quality control standards

- Ask about opportunities for professional development and advancement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cupola Melter Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!