Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cupola Melter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cupola Melter so you can tailor your answers to impress potential employers.

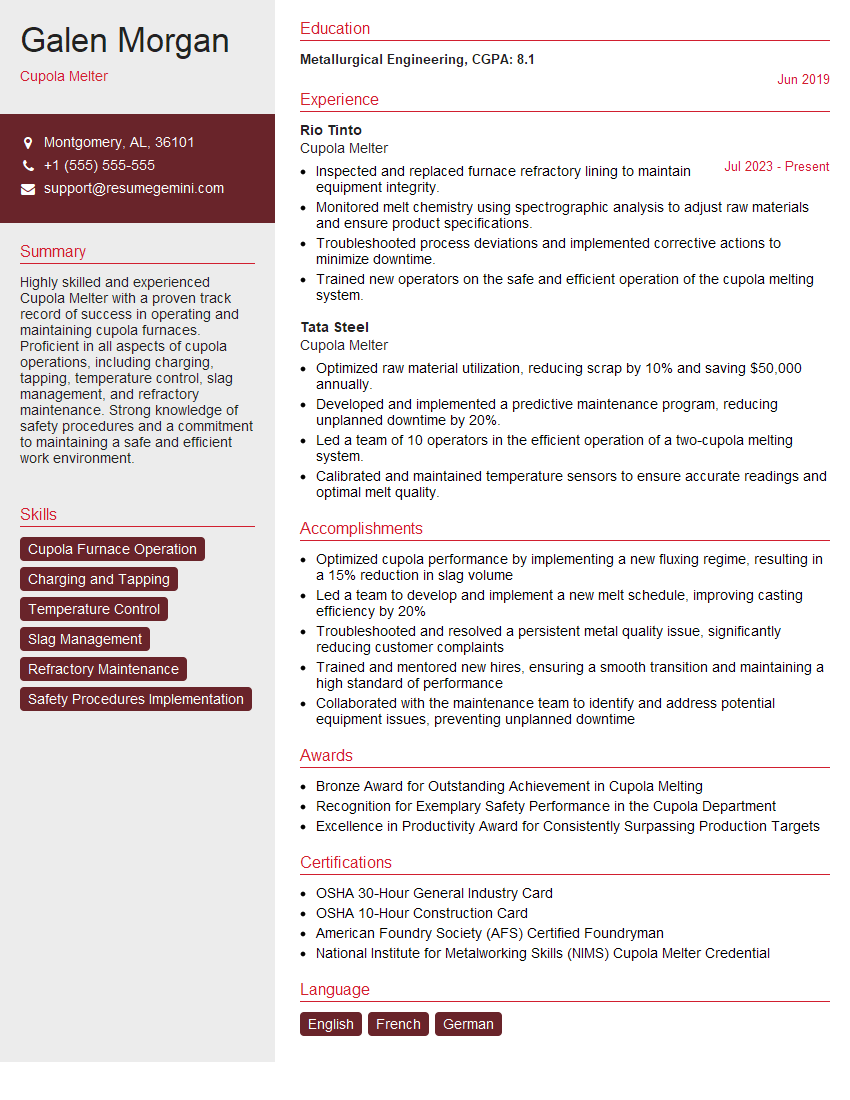

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Melter

1. Describe the essential procedures and techniques involved in operating a cupola furnace?

- Loading the furnace with raw materials (scrap metal, coke, and flux)

- Starting the furnace and maintaining a steady burn rate

- Monitoring the temperature and flow of molten metal

- Adjusting the furnace settings to optimize the melting process

- Troubleshooting and resolving any issues that arise during operation

2. How do you ensure the quality of molten metal produced by the cupola furnace?

Quality Control Measures

- Regularly testing the composition and temperature of the molten metal

- Inspecting the furnace and equipment for any signs of wear or damage

- Following established operating procedures and protocols

Preventive Maintenance

- Performing routine maintenance and repairs to the furnace and equipment

- Monitoring the condition of refractories and replacing them as needed

3. Discuss the importance of maintaining a proper coke-to-metal ratio in the cupola furnace?

- Ensures efficient combustion and heat generation

- Controls the temperature and fluidity of the molten metal

- Optimizes the melting rate and reduces energy consumption

- Improves the quality of the molten metal by reducing impurities

4. Describe the different types of charging methods used in cupola furnaces?

- Skip Charging: Materials are loaded into the furnace from a skip bucket

- Continuous Charging: Materials are fed into the furnace at a controlled rate

- Alternate Charging: Coke and metal are charged into the furnace in alternating layers

- Mechanical Charging: Materials are loaded into the furnace using mechanical conveyors

5. Explain the process of tapping the molten metal from the cupola furnace?

- Opening the tap hole at the bottom of the furnace

- Controlling the flow of molten metal using a tap hole stopper

- Collecting the molten metal in a ladle for further processing

- Closing the tap hole when tapping is complete

6. What are the potential hazards associated with operating a cupola furnace, and how do you mitigate them?

- Molten Metal: Wear appropriate protective gear, maintain a safe distance

- Hot Surfaces: Avoid touching hot surfaces, wear heat-resistant gloves

- Fumes and Gases: Ensure proper ventilation, use respirators if necessary

- Explosion: Implement safety protocols to prevent build-up of explosive gases

- Electrical Hazards: Ensure proper grounding, use insulated tools

7. How do you respond to an emergency situation involving the cupola furnace, such as a fire or a spill?

- Fire: Evacuate the area, call the fire department, use fire extinguishers if safe

- Spill: Contain the spill, evacuate the area, call the appropriate authorities

- Follow established emergency response procedures

8. What are the key performance indicators used to evaluate the operation of a cupola furnace?

- Melting rate

- Quality of molten metal

- Energy efficiency

- Downtime and maintenance requirements

- Environmental performance

9. Describe your experience in implementing process improvements to optimize the performance of a cupola furnace?

- Analyzing furnace data and identifying areas for improvement

- Developing and implementing new operating procedures

- Training operators on improved practices

- Monitoring results and making further adjustments as needed

- Achieved increased productivity, reduced energy consumption, and improved molten metal quality

10. How do you stay up-to-date with the latest advancements in cupola furnace technology and best practices?

- Attending industry conferences and workshops

- Reading technical publications and journals

- Consulting with equipment manufacturers and experts

- Participating in online forums and discussion groups

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Melter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Melter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cupola Melter is a specialized professional responsible for operating and maintaining cupola furnaces used in metalworking industries. Their primary job duties include:

1. Furnace Operation

Efficiently operate and control cupola furnaces to melt and refine metals according to production schedules and quality specifications.

- Monitor furnace temperatures, pressure, and other operating parameters to ensure optimal performance.

- Adjust furnace settings as required to maintain desired metal quality and prevent defects.

2. Charge Preparation and Charging

Prepare and load charge materials (e.g., iron, steel scrap, coke) into the cupola furnace.

- Calculate and weigh charge materials accurately based on production needs and specifications.

- Use conveyors, hoists, or other equipment to charge materials into the furnace safely and efficiently.

3. Slag Management

Control and manage slag formation in the furnace to ensure efficient melting and minimize defects.

- Monitor slag thickness and remove excess slag as necessary to prevent contamination.

- Operate slag removal systems to dispose of molten slag safely and environmentally.

4. Metal Tapping

Tap (release) molten metal from the furnace into ladles or other containers.

- Prepare ladles or containers for metal tapping, ensuring they are clean and dry.

- Control tapping temperature and volume to meet production specifications and quality requirements.

5. Equipment Maintenance

Perform basic maintenance and repairs on cupola furnaces and related equipment.

- Inspect equipment regularly and identify potential issues.

- Clean and lubricate furnace components to maintain optimal performance.

Interview Tips

To ace the interview for a Cupola Melter position, candidates can follow these tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, product line, and industry trends. This shows interest and preparation.

- Visit the company website and read recent news articles.

- Network with people in the industry to gain insights into the company culture and job requirements.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in cupola furnace operation, metalworking, and equipment maintenance.

- Quantify your accomplishments and provide specific examples of how you contributed to successful production processes.

- If possible, obtain references from previous supervisors or colleagues who can attest to your abilities.

3. Demonstrate Safety Awareness

Cupola furnaces involve high temperatures and molten metal handling, so safety is paramount.

- Explain your understanding of safety protocols and how you ensure a safe work environment.

- Mention any safety certifications or training you have completed.

4. Be Enthusiastic and Professional

Convey your passion for metalworking and your desire to contribute to the company’s success.

- Be confident in your abilities and show genuine interest in the position.

- Dress professionally and arrive on time for the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cupola Melter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.