Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cupola Patcher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cupola Patcher so you can tailor your answers to impress potential employers.

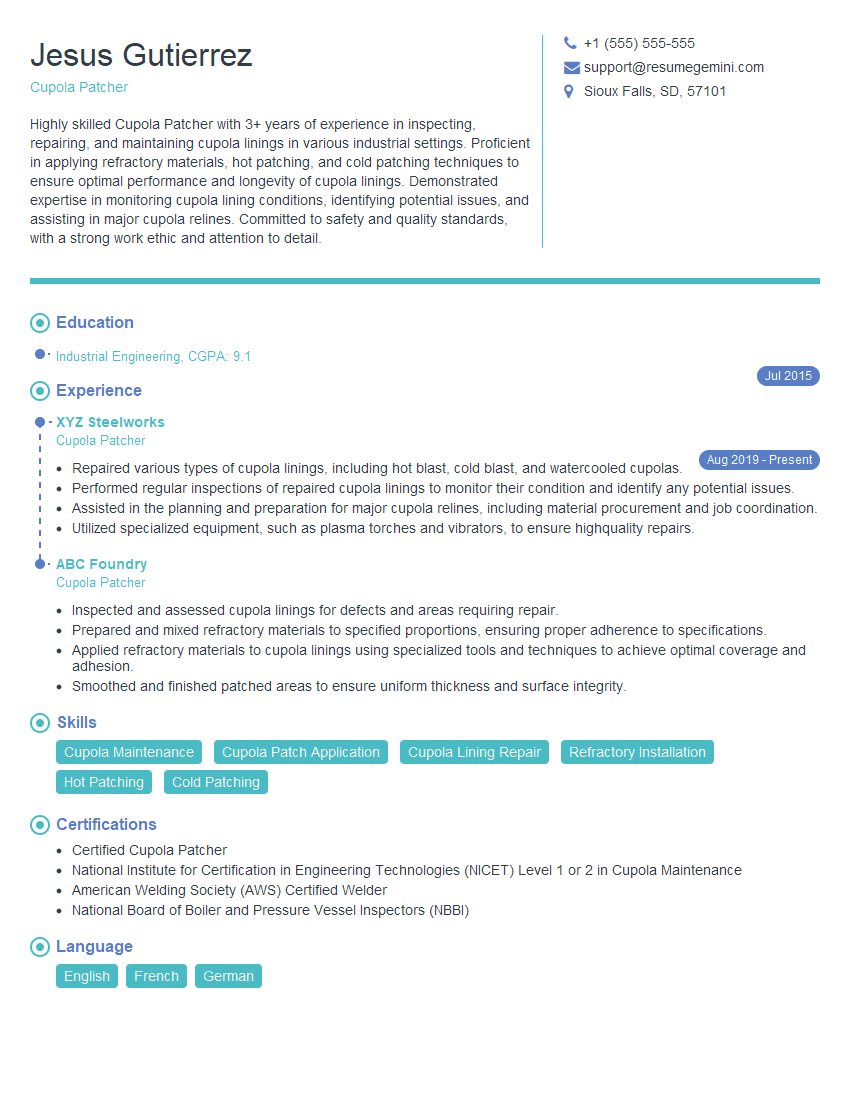

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Patcher

1. What is the role of a Cupola Patcher?

The primary role of a Cupola Patcher is to maintain and repair the cupola, a refractory-lined furnace used in steelmaking, foundries, and other industrial applications. They are responsible for repairing cracks, holes, and other defects in the cupola lining, as well as replacing worn-out or damaged components.

2. What are the key skills required to be a Cupola Patcher?

- Expert knowledge of cupola construction and operation

- Strong understanding of refractory materials and their properties

- Proficiency in welding, cutting, and other metalworking techniques

- Ability to work independently and as part of a team

- Excellent problem-solving and troubleshooting skills

3. What are the common materials used for cupola patching?

- Fireclay

- Alumina-silica

- Magnesia-chrome

- Zirconia

- Carbon

4. Describe the process of repairing a crack in a cupola lining.

- Identify and mark the location of the crack.

- Remove any loose or damaged material around the crack.

- Apply a refractory patch to the crack using a trowel or gun.

- Allow the patch to cure according to the manufacturer’s instructions.

- Grind or smooth the patched area to ensure a uniform surface.

5. How do you ensure the safety of yourself and others while working on a cupola?

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, gloves, and fire-resistant clothing.

- Thoroughly inspect the cupola before starting work to identify any potential hazards.

- Follow established safety procedures and protocols.

- Be aware of the location of fire extinguishers and other emergency equipment.

- Never work alone on a cupola.

6. What are the potential risks associated with cupola patching?

- Exposure to heat and flames

- Contact with molten metal or slag

- Fumes and dust inhalation

- Falls and other physical hazards

- Electrical hazards

7. How do you determine the extent of damage to a cupola lining?

- Visual inspection

- Ultrasonic testing

- Radiographic testing

- Acoustic emission testing

- Eddy current testing

8. What are the different types of cupola patching tools and equipment?

- Trowels

- Guns

- Grinders

- Welders

- Cutters

9. How do you maintain and calibrate cupola patching tools and equipment?

- Regularly clean and inspect tools and equipment.

- Lubricate moving parts.

- Calibrate tools and equipment according to manufacturer’s instructions.

- Store tools and equipment in a dry and secure location.

10. What are the quality control procedures for cupola patching?

- Inspecting the patched area for cracks, holes, or other defects.

- Testing the patched area for leaks

- Ensuring that the patched area meets the required specifications

- Documenting the patching process and results

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Patcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Patcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cupola Patcher is responsible for maintaining and repairing cupolas, which are structures that form the tops of furnaces or kilns. The primary duties involve inspecting, preparing, and applying refractory materials, such as bricks and mortar, to create a protective lining inside the cupola.

1. Cupola Inspection and Preparation

Inspect cupolas for signs of wear, damage, or deterioration.

- Prepare work areas by cleaning and removing existing refractory materials.

- Measure and cut new refractory bricks to fit the required dimensions.

2. Refractory Material Application

Lay and secure refractory bricks inside the cupola, using mortar or other adhesive materials.

- Apply mortar or cement to seal and reinforce joints between bricks.

- Install anchors, bolts, or other hardware to stabilize the lining.

3. Cupola Maintenance

Monitor the condition of the cupola lining and make necessary repairs as needed.

- Identify and remove damaged bricks or mortar.

- Repair cracks or gaps in the lining using appropriate materials.

4. Safety and Housekeeping

Adhere to safety regulations and guidelines while working with dangerous materials.

- Wear appropriate protective gear, such as gloves, masks, and safety glasses.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Cupola Patcher position, it is essential to prepare thoroughly and demonstrate your skills and knowledge.

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and specific needs related to cupola maintenance.

- Study the job description to identify the most relevant qualifications and responsibilities.

- Research industry best practices and technological advancements in cupola patching.

2. Highlight Your Experience and Skills

Emphasize your hands-on experience in refractory materials handling, bricklaying, and cupola maintenance.

- Quantify your achievements with specific examples of projects or tasks completed.

- Demonstrate your understanding of safety protocols and industry regulations.

3. Showcase Your Problem-Solving Abilities

Provide examples of how you have identified and resolved problems related to cupola patching.

- Describe your approach to troubleshooting and finding innovative solutions.

- Discuss your ability to work independently and as part of a team.

4. Prepare for Behavioral Questions

Be ready to answer questions that assess your work ethic, communication skills, and adaptability.

- Use the STAR (Situation, Task, Action, Result) method to structure your responses.

- Provide specific examples that showcase your teamwork, attention to detail, and positive attitude.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cupola Patcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!