Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cupola Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

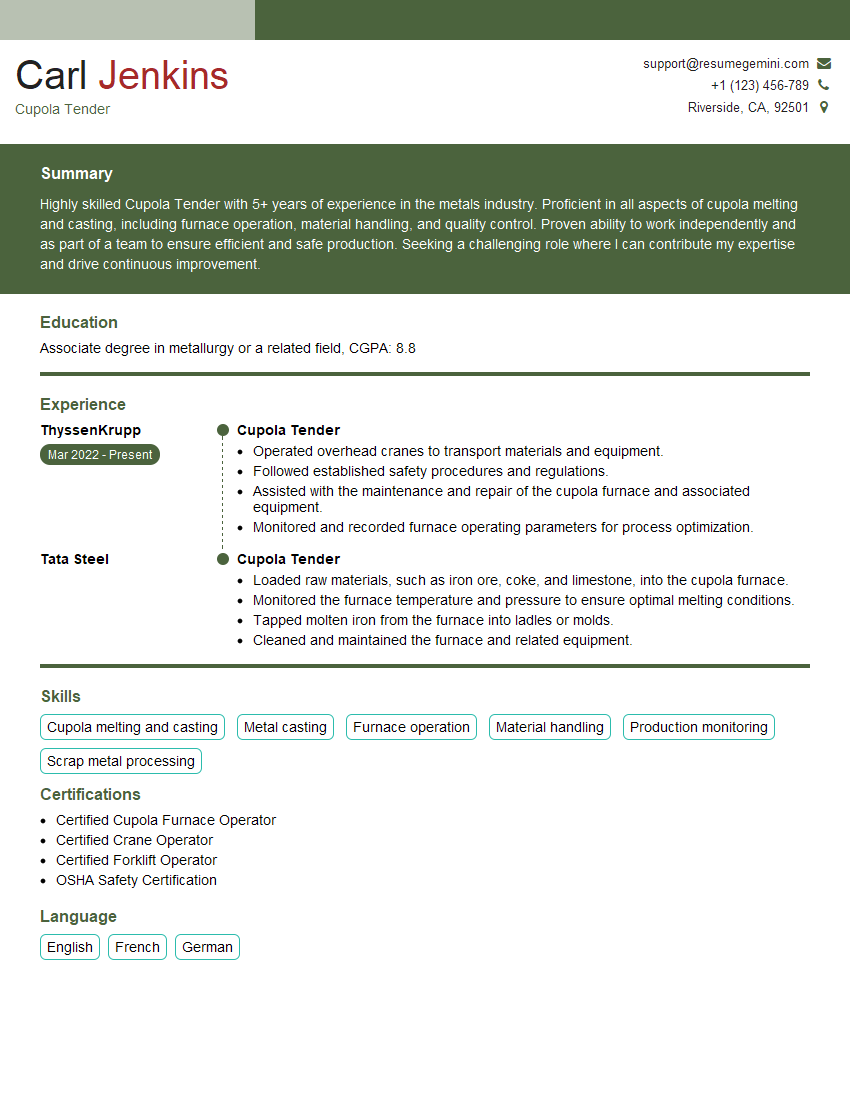

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cupola Tender

1. Can you explain the typical operating cycle of a cupola furnace?

- The cupola furnace is charged with coke, limestone, and iron.

- The coke is ignited and burns, creating heat.

- The limestone fluxes the impurities in the iron.

- The molten iron is tapped from the furnace and poured into molds.

2. What are the key factors that affect the quality of molten iron produced by a cupola furnace?

- The quality of the raw materials

- The operating temperature of the furnace

- The duration of the melting process

- The level of slag formation

3. How do you control the temperature of a cupola furnace?

- By varying the amount of coke in the charge

- By adjusting the air flow to the furnace

- By using a temperature-monitoring device

4. What are the signs of a malfunctioning cupola furnace?

- Excessive smoke production

- Poor quality molten iron

- Increased energy consumption

5. How do you maintain a cupola furnace to ensure optimal performance?

- Regular inspection and cleaning

- Calibration of temperature-monitoring devices

- Preventive maintenance of all mechanical components

6. What are the safety precautions that need to be taken when operating a cupola furnace?

- Wear appropriate personal protective equipment

- Follow all operating procedures

- Be aware of the potential hazards of molten metal

7. What is the purpose of slagging off a cupola furnace?

- To remove impurities from the molten iron

- To prevent the formation of slag in the furnace

- To improve the quality of the molten iron

8. How do you calculate the coke ratio for a cupola furnace?

- The coke ratio is the ratio of coke to iron in the charge.

- The coke ratio is typically between 1:8 and 1:10.

- The coke ratio is determined by the type of iron being melted and the desired quality of the molten iron.

9. What are the advantages of using a cupola furnace?

- High melting capacity

- Good quality molten iron

- Flexible operation

- Low operating costs

10. What are the disadvantages of using a cupola furnace?

- High energy consumption

- Environmental pollution

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cupola Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cupola Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cupola Tender is responsible for the operation, maintenance, and repair of a cupola furnace, which is used to melt metal for casting. The key job responsibilities include:

1. Operating the Cupola Furnace

This involves starting up, shutting down, and controlling the furnace to ensure optimal melting and casting operations.

- Lighting the cupola with appropriate fuel (coke)

- Charging the furnace with raw materials (metal scrap, limestone, and coke)

- Monitoring furnace temperatures and adjusting fuel and air flow to maintain desired melt conditions

- Tapping the molten metal from the furnace into a ladle for casting

2. Maintaining and Repairing the Cupola Furnace

Regular maintenance and repairs are crucial to ensure the efficient operation and longevity of the furnace.

- Inspecting the furnace lining and making repairs as needed

- Replacing worn or damaged parts, such as refractory bricks, tuyeres, and tuyere coolers

- Cleaning and lubricating moving parts

3. Monitoring and Controlling the Casting Process

The Cupola Tender ensures that the molten metal is properly prepared and poured into molds for casting.

- Adding alloying elements to the molten metal

- Skimming off impurities from the molten metal

- Controlling the pouring temperature and rate

4. Safety and Environmental Compliance

The Cupola Tender must strictly adhere to safety regulations and environmental standards.

- Wearing appropriate personal protective equipment (PPE)

- Following established safety procedures

- Monitoring and controlling emissions

Interview Tips

To ace the interview for a Cupola Tender position, candidates should prepare thoroughly and consider the following tips:

1. Research the Foundry and the Industry

Familiarize yourself with the specific foundry where you are applying and the industry in general. Learn about their products, processes, and safety standards.

2. Highlight Relevant Experience

Emphasize your prior experience in cupola operations, including any knowledge of different types of cupolas, melting practices, and safety protocols.

3. Demonstrate Safety Awareness

Stress your commitment to safety and your understanding of the hazards associated with cupola operations. Show that you are familiar with proper PPE and safe work practices.

4. Prepare for Technical Questions

Anticipate questions related to the technical aspects of cupola operation, such as furnace design, charging procedures, and molten metal handling.

5. Be Physically and Mentally Fit

Cupola Tender is a physically demanding job that requires endurance and attention to detail. Be prepared to demonstrate your physical fitness and mental alertness.

6. Show a Desire to Learn

Express your eagerness to learn more about cupola operations and contribute to the foundry’s success.

7. Practice Communication Skills

Effective communication is essential for reporting, coordination, and resolving issues. Show that you can clearly communicate both verbally and in writing.

8. Dress Professionally

First impressions matter. Dress professionally and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cupola Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!