Are you gearing up for an interview for a Cured Meat Packing Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cured Meat Packing Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

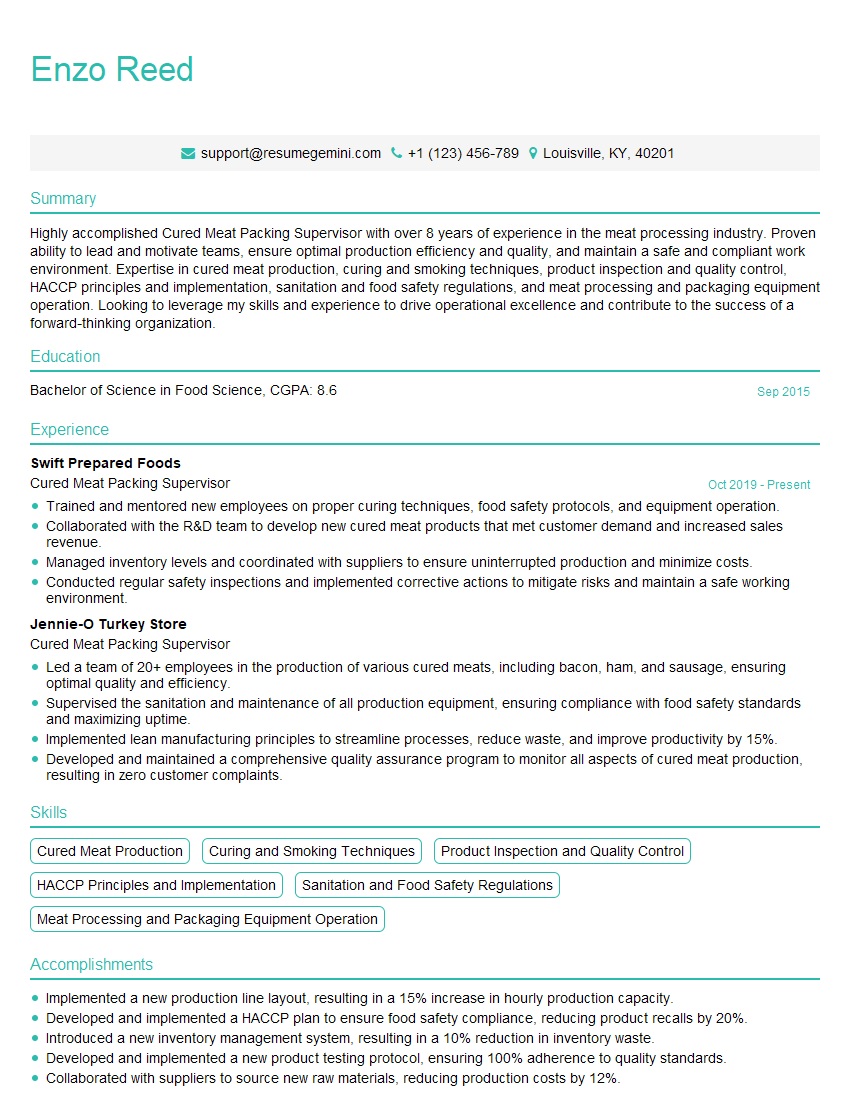

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cured Meat Packing Supervisor

1. What are the key responsibilities of a Cured Meat Packing Supervisor?

As a Cured Meat Packing Supervisor, my key responsibilities include:

- Overseeing the production and packaging of cured meats, ensuring compliance with safety and quality standards.

- Managing a team of production staff, including training, scheduling, and performance evaluation.

- Monitoring production processes, identifying areas for improvement, and implementing corrective actions.

- Maintaining a clean and organized work environment, adhering to sanitation and food safety protocols.

- Collaborating with other departments, such as purchasing, quality assurance, and sales, to ensure smooth operations.

2. How do you ensure the safety and quality of cured meat products?

Quality Control Measures

- Enforce strict adherence to hygiene and sanitation practices throughout the production process.

- Implement regular inspections and testing to verify the quality and safety of raw materials, in-process products, and finished goods.

- Maintain accurate documentation of all quality control measures, including inspection records, temperature logs, and corrective actions taken.

Training and Awareness

- Provide comprehensive training to all production staff on food safety principles, sanitation procedures, and product handling.

- Empower employees to identify and report any potential quality or safety concerns promptly.

- Foster a culture of continuous improvement and quality assurance throughout the team.

3. How do you manage production efficiency and minimize waste?

To manage production efficiency and minimize waste, I implement several strategies:

- Optimize production schedules to maximize equipment utilization and minimize downtime.

- Monitor production output and identify areas for improvement, such as bottlenecks or inefficiencies.

- Implement lean manufacturing principles, such as 5S and kaizen, to streamline processes and reduce waste.

- Collaborate with the purchasing department to ensure the timely and cost-effective procurement of raw materials.

- Train staff on proper product handling and storage techniques to minimize spoilage and damage.

4. How do you motivate and develop your team?

Motivating and developing my team is crucial to maintaining a high-performing and engaged workforce. I employ the following strategies:

- Set clear expectations, provide regular feedback, and recognize achievements.

- Foster a positive and supportive work environment where employees feel valued and respected.

- Provide opportunities for professional development, such as training, mentorship, and cross-training.

- Empower employees to take ownership of their work and make decisions within their scope of responsibility.

- Encourage collaboration and teamwork to foster a sense of camaraderie and shared goals.

5. How do you handle production emergencies or deviations from standard operating procedures?

In the event of production emergencies or deviations from standard operating procedures, I follow a structured approach:

- Assess the situation quickly and identify the source of the problem.

- Communicate clearly with the team and implement contingency measures to minimize disruption.

- Investigate the root cause of the deviation and develop corrective actions to prevent recurrence.

- Document the incident thoroughly and report it to management as necessary.

- Conduct follow-up inspections to ensure that the corrective actions are effective.

6. What are the challenges and opportunities in the cured meat packing industry?

Challenges

- Maintaining food safety and quality standards in a highly regulated environment.

- Meeting increasing consumer demand for healthier and more sustainable meat products.

- Managing supply chain disruptions and rising production costs.

Opportunities

- Growing demand for cured meat products in emerging markets.

- Development of innovative packaging and preservation technologies.

- Collaboration with research institutions to develop new products and processes.

7. How do you stay up-to-date with industry trends and best practices?

To stay up-to-date with industry trends and best practices, I:

- Attend industry conferences and workshops.

- Read trade publications and research journals.

- Network with other professionals in the field.

- Participate in continuing education programs.

- Seek out opportunities to visit other cured meat packing facilities and learn from their experiences.

8. How would you handle a situation where a customer complaint arises regarding the quality or safety of a product?

In the event of a customer complaint:

- Acknowledge the complaint promptly and apologize for any inconvenience caused.

- Investigate the complaint thoroughly to determine the root cause.

- Implement corrective actions to address the issue and prevent recurrence.

- Communicate the findings and resolution to the customer in a timely and transparent manner.

- Monitor the situation closely to ensure customer satisfaction.

9. Describe your experience in implementing HACCP (Hazard Analysis and Critical Control Points) principles in a cured meat packing facility.

In my previous role, I was responsible for implementing HACCP principles in a cured meat packing facility:

- Conducted a thorough hazard analysis to identify potential food safety hazards.

- Established critical control points (CCPs) and set critical limits to prevent, eliminate, or reduce hazards.

- Developed monitoring procedures to ensure that CCPs are operating effectively.

- Trained staff on HACCP principles and their roles in maintaining food safety.

- Regularly reviewed and updated the HACCP plan to ensure its effectiveness.

10. How do you ensure compliance with regulatory requirements governing the production of cured meat products?

To ensure compliance with regulatory requirements:

- Maintain a thorough understanding of all applicable regulations.

- Develop and implement policies and procedures to ensure compliance.

- Conduct regular self-inspections to identify and address any areas of non-compliance.

- Work closely with regulatory agencies to ensure compliance and address any concerns.

- Stay up-to-date on changes in regulations and industry best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cured Meat Packing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cured Meat Packing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cured Meat Packing Supervisor oversees the production of cured meat products, ensuring adherence to safety and quality standards, and optimizing production processes to maximize efficiency and minimize costs.

1. Production Management

Plan and schedule production activities, allocating resources and coordinating with other departments to ensure timely completion.

- Establish production goals and targets, monitoring progress and making adjustments as needed.

- Identify and resolve production bottlenecks, implementing process improvements to enhance efficiency.

2. Quality Control

Enforce adherence to quality standards, ensuring that all cured meat products meet specifications.

- Inspect raw materials and finished products, identifying and rejecting defective items.

- Monitor production processes, identifying and addressing deviations from established parameters.

3. Safety Compliance

Maintain a safe and hygienic work environment, complying with all applicable regulations.

- Develop and implement safety procedures, training employees on proper handling and storage techniques.

- Conduct regular safety inspections, identifying and mitigating potential hazards.

4. Team Management

Motivate and lead a team of production employees, fostering a positive and productive work environment.

- Provide training and development opportunities to enhance employee skills and knowledge.

- Evaluate employee performance, providing constructive feedback and recognizing achievements.

Interview Tips

To ace your interview for a Cured Meat Packing Supervisor position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s products, processes, and market position. Understand the industry’s trends and challenges, showing that you have a well-rounded view of the business.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in production management, quality control, safety compliance, and team leadership. Provide specific examples of your accomplishments and how you have contributed to the success of previous organizations.

- Quantify your achievements whenever possible, using metrics such as increased production efficiency or reduced quality defects.

- Be prepared to discuss how you have handled challenges and overcome obstacles in previous roles.

3. Show Your Passion for the Industry

Express your enthusiasm for the cured meat industry and your commitment to producing high-quality products. Demonstrate your understanding of the unique challenges and opportunities involved in this field.

- Share examples of your personal interest in cured meat products or your experience in related hobbies, such as cooking or grilling.

- Explain how your passion for the industry motivates you to excel in your work.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions that demonstrate your understanding of the role and the company, and that explore areas that were not covered in detail during the interview.

- Ask about the company’s growth plans and how the role fits into those plans.

- Inquire about the company’s commitment to sustainability and food safety.

Next Step:

Now that you’re armed with the knowledge of Cured Meat Packing Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cured Meat Packing Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini