Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Curing Oven Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Curing Oven Tender so you can tailor your answers to impress potential employers.

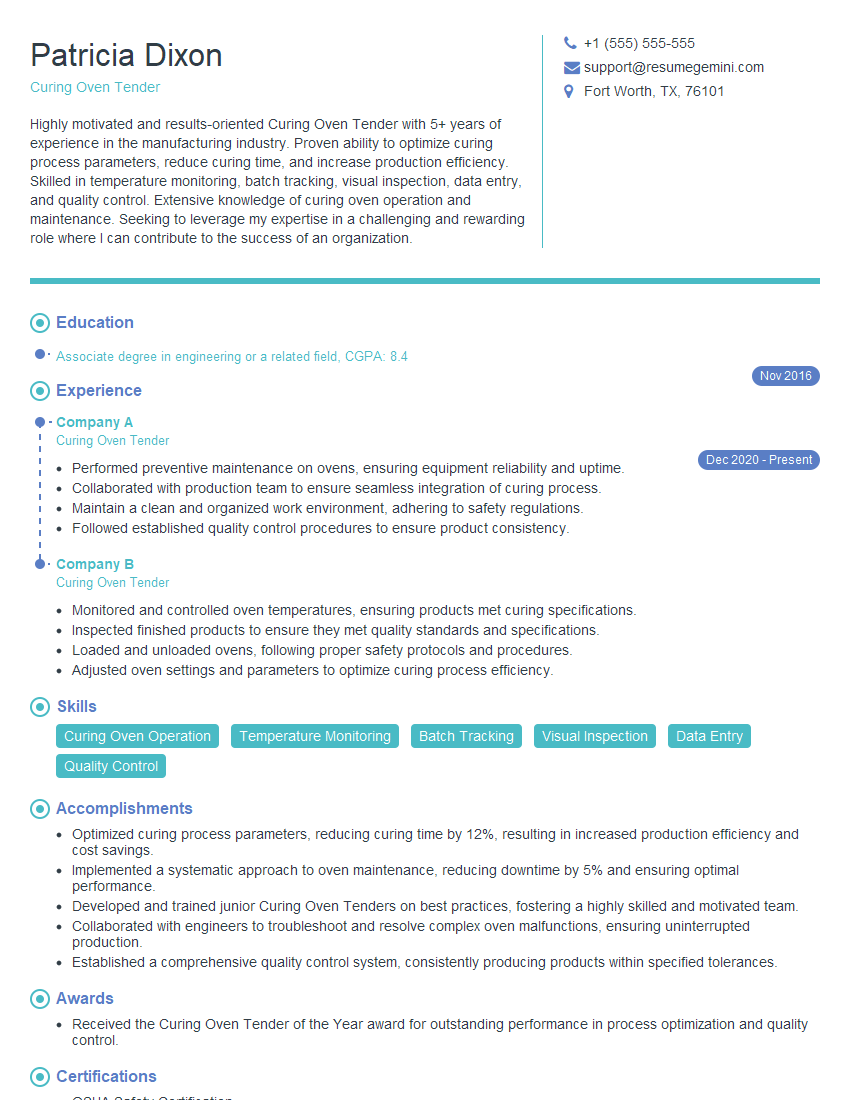

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Curing Oven Tender

1. Explain your understanding of curing oven operations.

- Preheat and maintain oven temperature according to specifications.

- Load and unload products into and out of the oven using proper handling techniques.

- Monitor oven temperature, humidity, and other critical parameters.

- Monitor product quality and make adjustments as needed.

- Maintain a clean and safe work environment.

2. Describe the types of products that can be cured in an oven.

Metal components

- Automotive parts

- Aerospace components

Composite materials

- Aircraft parts

- Wind turbine blades

Rubber and plastics

- Tires

- Medical devices

3. What are the different stages of the curing process?

- Preheating

- Curing

- Cooling

4. What are the key factors that affect the curing process?

- Oven temperature

- Curing time

- Humidity

- Product thickness

- Material type

5. How do you troubleshoot common curing oven problems?

- Uneven heating

- Product defects

- Oven malfunction

6. What are the safety precautions that must be followed when operating a curing oven?

- Wear appropriate protective clothing, including gloves, safety glasses, and a respirator.

- Do not enter the oven while it is in operation.

- Be aware of the location of fire extinguishers and other emergency equipment.

- Follow all manufacturer’s instructions for safe operation.

7. How do you maintain and calibrate a curing oven?

- Clean the oven regularly.

- Inspect the oven for any damage or wear.

- Calibrate the oven temperature and humidity sensors.

8. What are the quality control procedures that are followed in a curing oven operation?

- Inspect products before and after curing.

- Monitor oven temperature and humidity.

- Record curing parameters.

- Perform regular product testing.

9. What are the different types of curing ovens?

- Batch ovens

- Conveyor ovens

- Microwave ovens

- Radio frequency ovens

10. What are the advantages and disadvantages of different types of curing ovens?

Batch ovens

Advantages

- Can handle large batches of products.

- Can be used for a variety of products.

Disadvantages

- Slow curing time.

- Can be difficult to control temperature and humidity.

Conveyor ovens

Advantages

- Fast curing time.

- Easy to control temperature and humidity.

Disadvantages

- Can only handle small batches of products.

- Can be expensive to purchase and operate.

Microwave ovens

Advantages

- Fast curing time.

- Compact size.

Disadvantages

- Can only handle small batches of products.

- Can be expensive to purchase and operate.

Radio frequency ovens

Advantages

- Fast curing time.

- Can be used for a variety of products.

Disadvantages

- Can be expensive to purchase and operate.

- Can generate electromagnetic radiation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Curing Oven Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Curing Oven Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Curing Oven Tender is a skilled professional responsible for monitoring, maintaining, and controlling curing ovens used in manufacturing processes to enhance product quality and durability. Their primary duties involve ensuring optimal curing conditions, handling materials effectively, and monitoring oven performance to achieve desired results.

1. Oven Operation and Monitoring

Ensuring proper operation of curing ovens, including temperature, humidity, and airflow controls.

- Monitoring oven conditions and make adjustments as needed to maintain optimal curing environment.

- Inspecting ovens regularly to detect any malfunctions or defects and reporting them promptly.

2. Material Handling

Loading and unloading materials into and out of curing ovens, utilizing proper techniques to prevent damage.

- Loading materials into curing ovens in a manner that ensures proper placement, spacing, and airflow.

- Unloading cured materials from ovens, ensuring that they meet quality standards and specifications.

3. Process Control and Monitoring

Monitoring and controlling oven processes to achieve desired curing results, ensuring product quality.

- Monitoring curing time and temperature to ensure proper curing cycles.

- Assessing cured materials for quality and adherence to specifications, identifying any deviations or defects.

4. Safety and Maintenance

Ensuring a safe and efficient work environment, performing routine maintenance and adhering to safety protocols.

- Following established safety procedures, wearing appropriate personal protective equipment, and maintaining a clean and organized work area.

- Performing routine maintenance and cleaning of curing ovens, ensuring optimal performance and longevity.

Interview Tips

Preparing for an interview for a Curing Oven Tender position requires a thorough understanding of the role and the industry. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s business, products, and industry. Research the specific role, its responsibilities, and the qualifications required.

- Visit the company website to learn about their mission, values, and recent news.

- Review industry publications, articles, and online forums to gain insights into the role and industry trends.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating curing ovens, handling materials, and monitoring processes. Showcase your technical skills, attention to detail, and problem-solving abilities.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

- Prepare examples of situations where you identified and resolved problems related to curing processes or equipment.

3. Demonstrate Safety and Quality Awareness

Highlight your commitment to safety and quality by discussing your adherence to safety protocols and your ability to maintain a clean and organized work environment.

- Share examples of how you have implemented safety measures or improved quality control in previous roles.

- Explain your understanding of the importance of following established procedures and maintaining industry standards.

4. Be Prepared to Discuss Technical Knowledge

Review the technical aspects of curing processes, including temperature, humidity, and airflow control. Be ready to discuss your understanding of these parameters and how they affect the curing results.

- Research different types of curing ovens and their applications.

- Prepare to explain how you monitor and control specific curing processes based on material properties and desired outcomes.

5. Practice and Prepare Questions

Practice answering common interview questions related to your experience, skills, and career goals. Prepare thoughtful questions to ask the interviewer that demonstrate your interest and engagement.

- Consider questions about the company’s curing processes, industry best practices, or growth opportunities.

- Prepare open-ended questions that encourage the interviewer to provide more information and insights into the role and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Curing Oven Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.