Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Curing Pickling Packer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

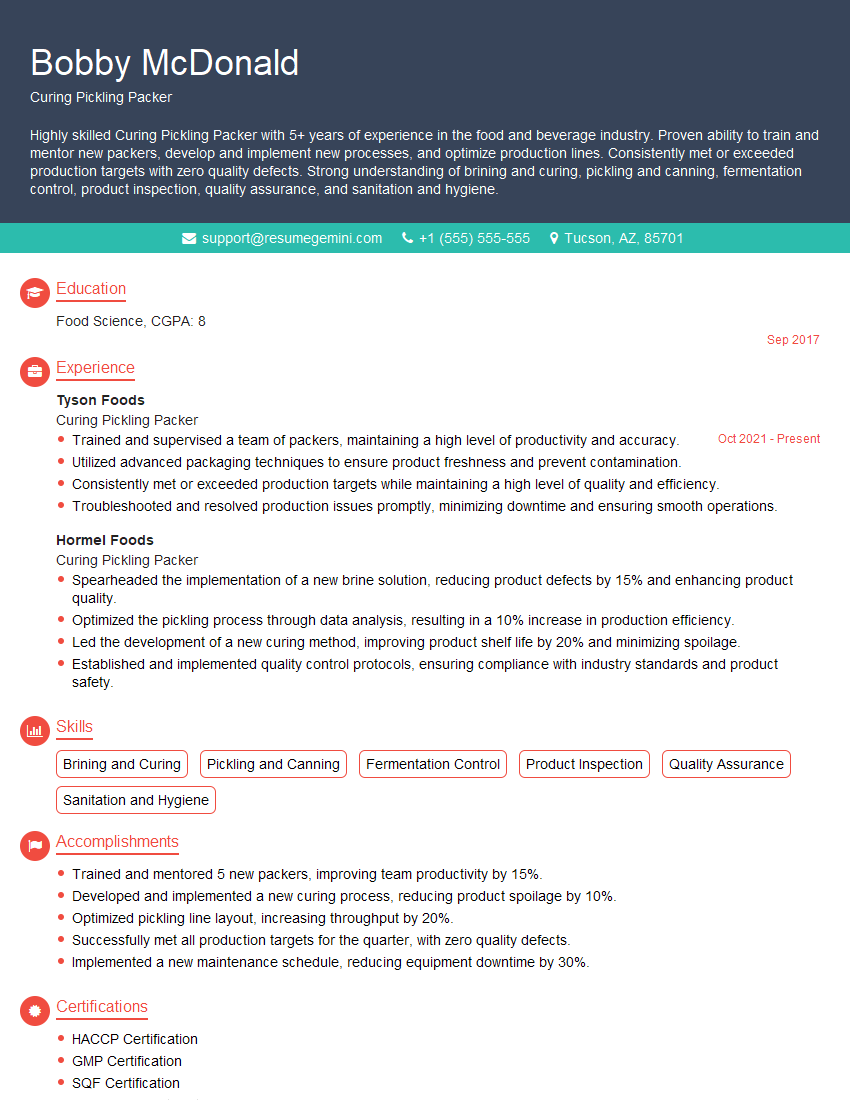

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Curing Pickling Packer

1: What types of equipment are you familiar with in a curing and pickling operation?

I have experience with a variety of equipment used in curing and pickling operations, including:

- Brine tanks and curing vats

- Salting and pickling machines

- Conveyor systems

- Packaging equipment

- Sanitation and cleaning equipment

2: What are the key factors to consider when selecting a curing or pickling method?

Product quality

- Desired flavor and texture

- Shelf life and stability

Operational efficiency

- Equipment availability and cost

- Labor requirements

- Production capacity

3: What are the different types of brines used in curing and pickling?

There are several types of brines used in curing and pickling, including:

- Salt brine: Made from water and salt

- Sugar brine: Made from water, salt, and sugar

- Mixed brine: Made from water, salt, sugar, and other ingredients such as spices or vinegar

- Acid brine: Made from water, salt, and an acid such as vinegar or citric acid

4: What are the critical parameters to monitor during the curing or pickling process?

The critical parameters to monitor during the curing or pickling process include:

- Temperature

- pH

- Salt concentration

- Acidity

- Microbiological activity

5: What are the common defects in cured or pickled products and their causes?

Some common defects in cured or pickled products and their causes include:

- Soft texture: Under-curing or excessive water absorption

- Tough texture: Over-curing or insufficient moisture penetration

- Discoloration: Exposure to light or oxygen, or microbial spoilage

- Off-flavors: Microbial spoilage, improper curing conditions, or contamination

- Spoilage: Microbial contamination or inadequate preservation

6: What are the safety precautions to be taken when handling and using curing and pickling agents?

When handling and using curing and pickling agents, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a mask or respirator

- Handle chemicals in a well-ventilated area

- Follow all manufacturer’s instructions and safety guidelines

- Store chemicals safely and securely, away from food and other incompatible materials

- Dispose of chemicals properly according to local regulations

7: What are the latest trends and advancements in curing and pickling technology?

Some of the latest trends and advancements in curing and pickling technology include:

- Use of high-pressure processing (HPP) to improve food safety and extend shelf life

- Development of new curing and pickling agents that are more effective and safer

- Automation and modernization of curing and pickling processes

- Focus on sustainability and environmental friendliness

- Research into the health benefits of cured and pickled products

8: What are the different quality control measures implemented in a curing and pickling operation?

Quality control measures implemented in a curing and pickling operation include:

- Raw material inspection

- Process monitoring and control

- Product testing and analysis

- Sensory evaluation

- Sanitation and hygiene audits

- Traceability and documentation

9: What is the role of sanitation and hygiene in a curing and pickling operation?

Sanitation and hygiene play a critical role in a curing and pickling operation to prevent contamination and ensure the safety and quality of the products. Measures include:

- Maintaining a clean and sanitized work environment

- Regular cleaning and disinfection of equipment and surfaces

- Proper handling and storage of food and ingredients

- Monitoring and controlling temperature and humidity

- Training and educating employees on food safety practices

10: What are the key challenges faced in the curing and pickling industry?

The curing and pickling industry faces several challenges, including:

- Ensuring food safety and quality

- Meeting consumer demand for healthier and more sustainable products

- Managing costs and maintaining profitability

- Complying with regulatory requirements

- Staying competitive in a global market

- Recruiting and retaining skilled workers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Curing Pickling Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Curing Pickling Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Curing Pickling Packers are responsible for a wide range of tasks in the food processing industry. Their key responsibilities include:

1. Preparing and Curing Meat

Packers prepare meat for curing by trimming excess fat and connective tissue and then applying a curing solution to the meat. The curing solution typically contains salt, sugar, and spices, and it helps to preserve the meat and give it its characteristic flavor.

- Trimming and preparing meat cuts for curing

- Applying curing solutions to meat to enhance flavor and preservation

2. Packing and Storing Meat

Once the meat has been cured, packers pack it into containers for storage and distribution. They may also label the containers with information such as the type of meat, the date it was packed, and the weight of the meat.

- Packing meat into containers for storage and distribution

- Labeling containers with necessary information

3. Quality Control

Packers are responsible for ensuring that the meat they pack meets quality standards. They may inspect the meat for defects, such as bruising or spoilage, and they may also test the meat to ensure that it is safe to eat.

- Inspecting meat for defects and spoilage

- Testing meat to ensure safety and quality

4. Sanitation

Packers must maintain a clean and sanitary work environment. They may clean and disinfect equipment, and they may also follow other sanitation procedures to prevent the spread of bacteria.

- Maintaining a clean and sanitary work environment

- Cleaning and disinfecting equipment

Interview Tips

To ace an interview for a Curing Pickling Packer position, it is important to prepare in advance. Here are a few tips to help you succeed:

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand the company’s culture, values, and goals. You can also learn more about the specific position you are applying for.

- Visit the company’s website

- Read industry news and articles about the company

- Connect with current or former employees on LinkedIn

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Use the STAR method to answer behavioral questions

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering questions about the company

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Choose conservative colors and styles

- Make sure your clothes fit well

- Pay attention to your grooming

4. Be Enthusiastic

Employers are looking for candidates who are enthusiastic about the job they are applying for. Show your enthusiasm by asking thoughtful questions, making eye contact, and smiling.

- Ask questions about the company, the position, and the industry

- Make eye contact with the interviewer

- Smile and be friendly

5. Follow Up

After your interview, send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank the interviewer for their time.

- Send a thank-you note within 24 hours of your interview

- Reiterate your interest in the position

- Thank the interviewer for their time

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Curing Pickling Packer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Curing Pickling Packer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.