Are you gearing up for an interview for a Curing Press Maintainer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Curing Press Maintainer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

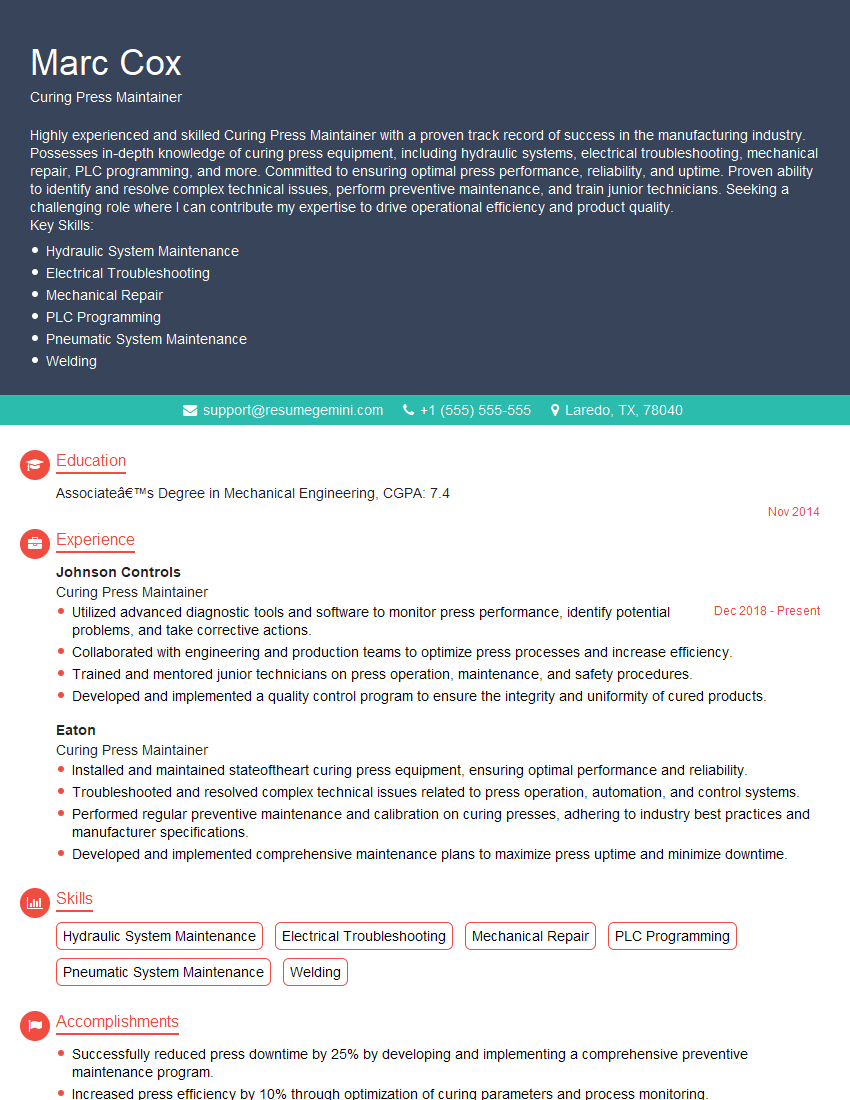

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Curing Press Maintainer

1. What are the key responsibilities of a Curing Press Maintainer?

- Maintaining and repairing curing presses and related equipment

- Installing new presses and equipment

- Troubleshooting and resolving mechanical and electrical problems

- Performing preventive maintenance and inspections

- Collaborating with production team to ensure smooth operation of presses

2. What are the most common issues you have encountered with curing presses?

Problem 1

- Pressure loss in the press

- Causes: Faulty valves, leaks in hoses or fittings

- Solution: Inspect and replace faulty components

Problem 2

- Overheating of the press

- Causes: Malfunctioning cooling system, clogged filters

- Solution: Clean filters, repair or replace cooling system components

Problem 3

- Uneven curing of materials

- Causes: Incorrect temperature or pressure settings, faulty heating elements

- Solution: Calibrate press settings, inspect and replace heating elements

3. What safety precautions should be taken when working with curing presses?

- Wear appropriate PPE, including safety glasses, gloves, and earplugs

- Never operate a press without proper training

- Keep work area clean and free of tripping hazards

- Inspect press and equipment regularly for any signs of damage or wear

- Follow all lockout/tagout procedures when performing maintenance

4. What are the different types of curing presses and their applications?

- Compression molding presses: Used for molding rubber, plastic, and composite materials

- Transfer molding presses: Used for molding thermosetting plastics

- Injection molding presses: Used for molding thermoplastic materials

- Vacuum forming presses: Used for forming plastic sheets into complex shapes

- Extrusion presses: Used for producing continuous profiles of plastic materials

5. What are the key performance indicators for a Curing Press Maintainer?

- Press uptime and efficiency

- Quality of cured products

- Maintenance costs and frequency

- Safety record

- Customer satisfaction

6. What are some of the latest advancements in curing press technology?

- Automated press controls and monitoring systems

- Use of advanced materials for press components

- Integration with Industry 4.0 technologies

- Development of new curing techniques, such as microwave and radio frequency curing

- Focus on energy efficiency and sustainability

7. How do you stay up-to-date with the latest industry trends and best practices?

- Attending industry conferences and webinars

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Seeking training and certification opportunities

- Networking with other professionals in the field

8. What are your strengths and weaknesses as a Curing Press Maintainer?

- Strong technical skills in mechanical and electrical maintenance

- Deep understanding of curing press operation and troubleshooting

- Excellent communication and interpersonal skills

- Proven ability to work independently and as part of a team

- Commitment to safety and quality

- Limited experience with certain types of curing presses

- Can sometimes be too detail-oriented

- Not always comfortable working under pressure

Strengths:

Weaknesses:

9. Why are you interested in this Curing Press Maintainer position?

- Excited by the opportunity to contribute my skills to your team

- Impressed by your company’s reputation for quality and innovation

- Believing that my experience and knowledge would be a valuable asset to your operation

- Eager to learn and grow as a professional in this field

- Confident that I can make a positive impact on your company’s success

10. What are your salary expectations for this position?

- My salary expectations are in line with the market average for similar positions

- I am confident that my skills and experience are worth the investment

- I am open to discussing a salary range that is fair and competitive for both parties

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Curing Press Maintainer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Curing Press Maintainer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Curing Press Maintainers are responsible for ensuring the proper functioning of curing presses used in the manufacturing process.

1. Maintain and Repair Curing Presses

Curing Press Maintainers are responsible for performing regular maintenance and repairs on curing presses. This includes inspecting presses for any signs of wear or damage, and making necessary repairs to ensure optimal performance.

- Inspect presses for any signs of wear or damage.

- Make necessary repairs to ensure optimal performance.

2. Monitor Press Performance

Curing Press Maintainers are responsible for monitoring the performance of curing presses to ensure that they are operating efficiently. This includes monitoring temperature, pressure, and other process parameters.

- Monitor temperature, pressure, and other process parameters.

- Make adjustments to ensure optimal performance.

3. Troubleshoot and Resolve Press Problems

Curing Press Maintainers are responsible for troubleshooting and resolving any problems that may occur with curing presses. This includes identifying the root cause of the problem and taking steps to resolve it.

- Identify the root cause of the problem.

- Take steps to resolve the problem.

4. Train and Supervise Operators

Curing Press Maintainers are responsible for training and supervising press operators. This includes providing instruction on how to operate presses safely and efficiently, and ensuring that operators are following proper procedures.

- Provide instruction on how to operate presses safely and efficiently.

- Ensure that operators are following proper procedures.

Interview Tips

To ace your interview for a Curing Press Maintainer position, it is important to be well-prepared. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture, goals, and needs, and will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read news articles and press releases about the company.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering common interview questions. This will help you feel more confident and prepared when you are actually in the interview.

- Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Avoid wearing casual clothes, such as jeans or t-shirts.

- Instead, opt for more formal attire, such as a suit or dress.

4. Be Polite and Respectful

Throughout the interview, it is important to be polite and respectful to the interviewer. This means being on time for your interview, making eye contact, and listening attentively to the interviewer’s questions.

- Avoid interrupting the interviewer or speaking over them.

- Instead, wait your turn to speak and be respectful of the interviewer’s time.

Next Step:

Now that you’re armed with the knowledge of Curing Press Maintainer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Curing Press Maintainer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini