Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cut-and-Print Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

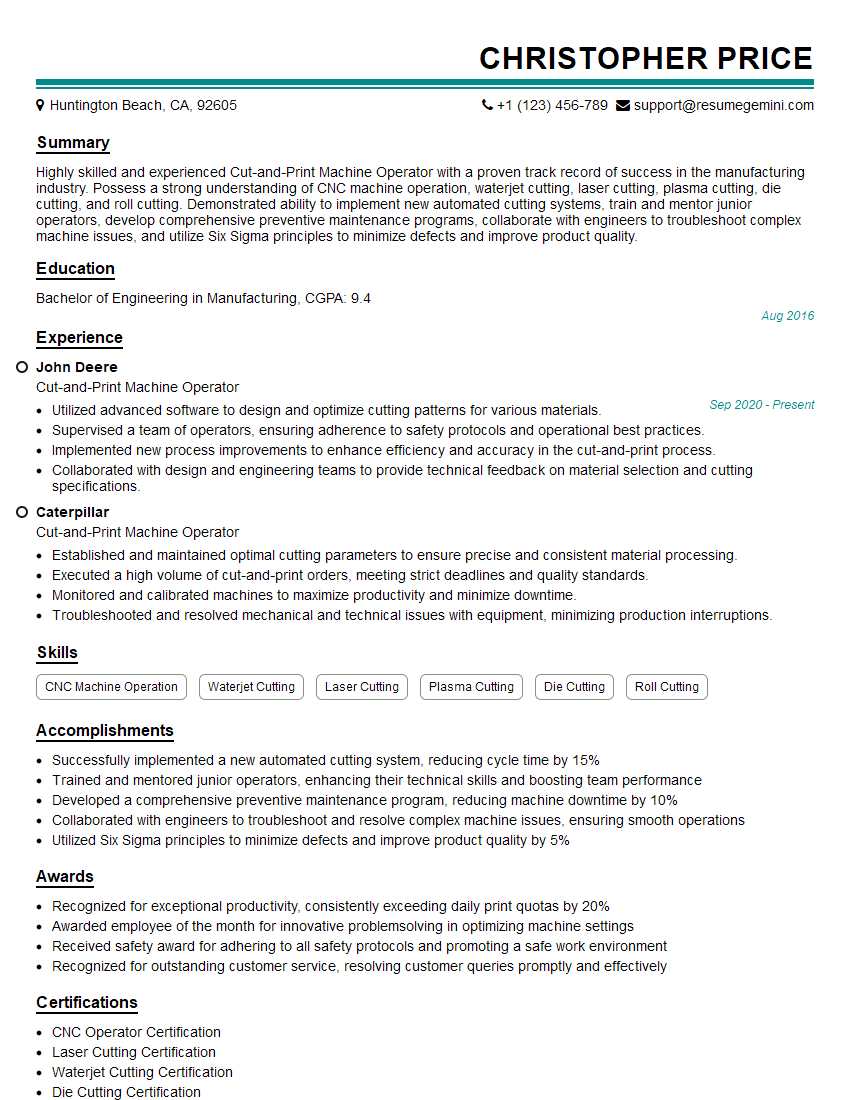

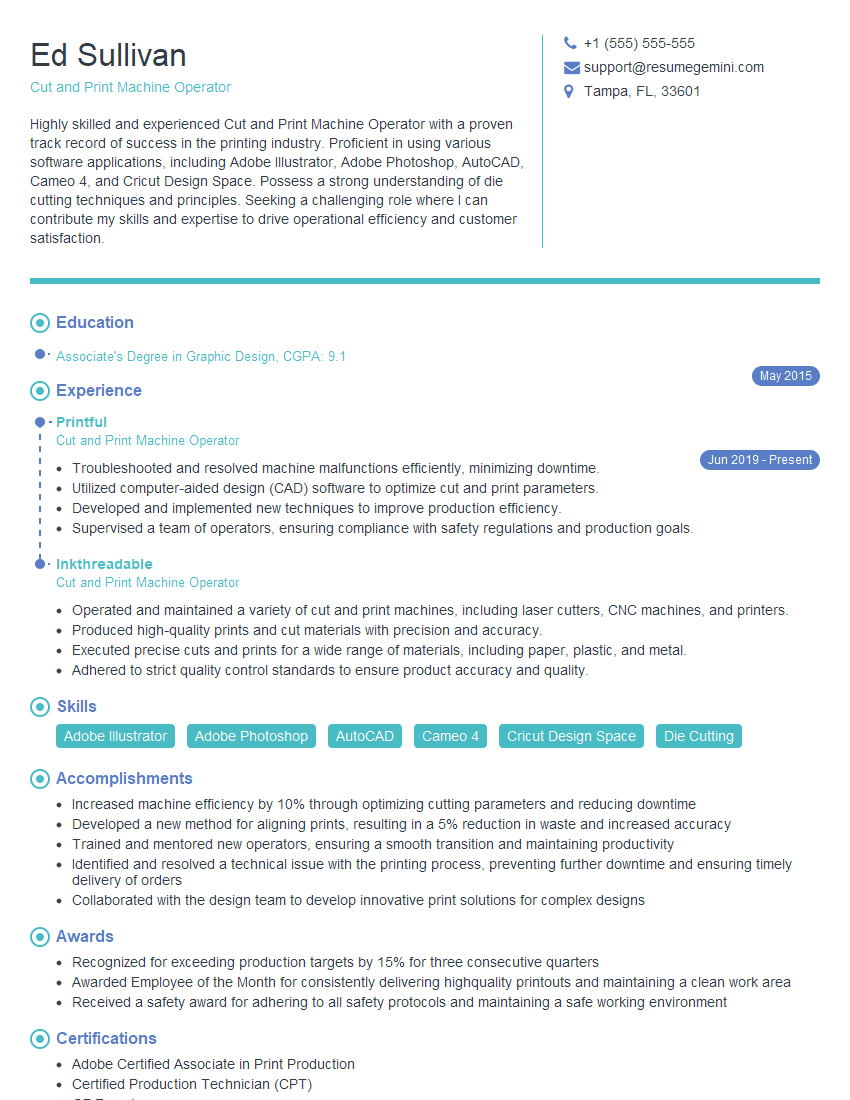

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut-and-Print Machine Operator

1. What are the essential safety precautions you follow when operating a cut-and-print machine?

To ensure a safe work environment, I strictly adhere to the following precautions:

- Always wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Inspect the machine thoroughly before each use, checking for any defects or damage.

- Ensure that the work area is well-lit and free from tripping hazards or obstructions.

- Keep hands and loose clothing away from moving parts while the machine is in operation.

- Never attempt to remove material from the machine while it is running.

2. Explain the process of setting up a cut-and-print machine for a new job.

Setting up the Machine

- Review the job specifications and select the appropriate cutting dies and printing plates.

- Install the dies and plates into the machine according to the manufacturer’s instructions.

- Calibrate the machine to ensure precise cutting and printing.

Preparing the Material

- Load the material into the machine’s feeder.

- Adjust the machine’s settings to match the thickness and type of material.

- Run a few test cuts to ensure accuracy and quality.

3. How do you troubleshoot common problems encountered during cut-and-print operations?

To efficiently troubleshoot common issues, I follow a systematic approach:

- Identify the problem by observing the machine’s behavior and reviewing error messages.

- Consult the machine’s manual or technical documentation for possible causes and solutions.

- Check for loose connections, worn parts, or material jams.

- Perform necessary adjustments or repairs to resolve the problem.

- Test the machine’s functionality after troubleshooting to ensure it is operating correctly.

4. How do you maintain the quality and accuracy of cut-and-print products?

Maintaining product quality and accuracy is crucial. I implement the following measures:

- Regularly inspect and clean the machine’s components to remove any debris or dust.

- Calibrate the machine periodically to ensure precise cutting and printing.

- Use high-quality materials and consumables to prevent defects.

- Monitor the machine’s performance during production and make adjustments as needed.

- Inspect finished products thoroughly for any errors or inconsistencies.

5. Describe the role of maintenance in extending the lifespan of a cut-and-print machine.

Regular maintenance is vital for maximizing the machine’s lifespan and performance. I prioritize the following tasks:

- Lubricate moving parts regularly to reduce wear and tear.

- Clean and inspect the machine thoroughly to identify potential issues early on.

- Replace worn or damaged parts promptly to prevent further deterioration.

- Perform preventive maintenance as recommended by the manufacturer.

- Keep a maintenance log to track all inspections and repairs.

6. What techniques do you use to optimize the efficiency of cut-and-print operations?

To enhance efficiency, I employ several techniques:

- Plan and prepare for jobs in advance, ensuring all materials and resources are ready.

- Use automated feeding systems to reduce manual labor and increase throughput.

- Optimize cutting and printing settings to minimize waste and maximize productivity.

- Monitor the machine’s performance and make adjustments to optimize speed and quality.

- Implement lean manufacturing principles to streamline processes and reduce downtime.

7. How do you ensure the accuracy of printed images on cut materials?

To guarantee precise printing, I pay close attention to the following aspects:

- Use high-resolution printing plates to achieve sharp and detailed images.

- Calibrate the machine’s printing settings to match the material’s characteristics.

- Inspect printed materials regularly for any registration errors or color variations.

- Maintain a consistent printing environment to prevent fluctuations in temperature or humidity.

- Use specialized software to optimize print settings and ensure image accuracy.

8. Describe your experience in working with different types of materials on cut-and-print machines.

Throughout my career, I have handled a wide range of materials, including:

- Paper and cardboard of various thicknesses and textures

- Plastic films and sheets

- Foils and laminates

- Textiles and fabrics

- Specialized materials such as reflective or magnetic films

9. How do you handle waste and scrap materials generated during cut-and-print operations?

To minimize waste and ensure environmental compliance, I adhere to the following practices:

- Optimize cutting patterns to reduce material wastage.

- Reuse scrap materials whenever possible, such as for smaller jobs or packaging.

- Implement a recycling program for paper, plastic, and other materials.

- Dispose of hazardous waste, such as inks and solvents, in accordance with regulations.

- Partner with waste management companies to ensure proper disposal and recycling.

10. What are your expectations and goals for this Cut-and-Print Machine Operator role?

I am eager to contribute my skills and experience to your team. My primary expectations and goals for this role are:

- Produce high-quality cut-and-print products that meet customer specifications.

- Operate the machine efficiently and safely, minimizing downtime and waste.

- Collaborate with colleagues to ensure smooth production processes.

- Identify and implement opportunities for process improvement.

- Contribute to the company’s overall productivity and profitability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut-and-Print Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut-and-Print Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Cut-and-Print Machine Operator

Cut-and-Print Machine Operators are responsible for operating and maintaining cut-and-print machines. This essential role in manufacturing ensures the production of accurately cut and printed materials. The key job responsibilities include:1. Operating Cut-and-Print Machines

Execute production runs on cut-and-print machines by placing materials, selecting appropriate settings, and monitoring the process.

- Load and unload materials into the machine.

- Control the speed and accuracy of the cuts and prints.

- Inspect printed materials for errors.

2. Machine Maintenance

Perform routine maintenance and cleaning to ensure optimal machine performance. Troubleshoot and resolve minor machine issues.

- Lubricate and clean machine parts.

- Replace worn or damaged components.

- Assist in major repairs as needed.

3. Quality Control

Inspect products to ensure they meet quality standards. Identify and rectify defects in a timely manner. Maintain accurate records of production and quality checks.

- Use measuring devices to ensure cuts and prints are within specifications.

- Check for color accuracy, clarity, and registration.

- Keep detailed logs of production and quality control measures.

4. Safety Compliance

Follow safety protocols to prevent accidents and maintain a clean and orderly work environment. Adhere to established company safety procedures.

- Wear appropriate personal protective equipment.

- Keep the work area clean and free of hazards.

- Report any safety concerns immediately.

5. Teamwork and Communication

Collaborate with other operators, machine technicians, and supervisors to achieve production goals. Communicate effectively to ensure smooth operations and timely problem resolution.

- Share information and assist colleagues.

- Report production issues promptly.

- Contribute to continuous improvement initiatives.

Interview Preparation Tips for a Cut-and-Print Machine Operator

Preparing thoroughly for an interview is crucial for success. Here are some tips to help you ace your Cut-and-Print Machine Operator interview:1. Research the Company and Position

Demonstrate your interest in the company and the role by researching their website, industry news, and social media. Understand the company’s products, services, and culture. This knowledge will help you tailor your answers and show enthusiasm.

- Practice answering common interview questions.

- Prepare specific examples to highlight your skills and experience.

- Be prepared to discuss your career goals and how they align with the company’s objectives.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating cut-and-print machines and your ability to maintain them effectively. Share examples of your quality control experience and how you ensure products meet specifications. Highlight your teamwork and communication skills, as well as your commitment to safety.

- Quantify your accomplishments whenever possible.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Be confident and articulate in presenting your skills.

3. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain eye contact, speak clearly, and be polite. Show enthusiasm for the role and the company. Ask thoughtful questions to demonstrate your interest and engagement.

- Prepare questions about the company, the position, and the industry.

- Be ready to discuss your availability and salary expectations.

- Follow up after the interview with a thank-you note.

4. Be Prepared to Discuss Safety

Safety is paramount in a manufacturing environment. Be prepared to discuss your understanding of safety protocols and your commitment to maintaining a safe work area. Explain how you would handle potential hazards and emergency situations.

- Share examples of your safety initiatives or certifications.

- Demonstrate your knowledge of industry safety regulations.

- Explain how you prioritize safety in your daily work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cut-and-Print Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.