Feeling lost in a sea of interview questions? Landed that dream interview for Cut-Off Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cut-Off Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

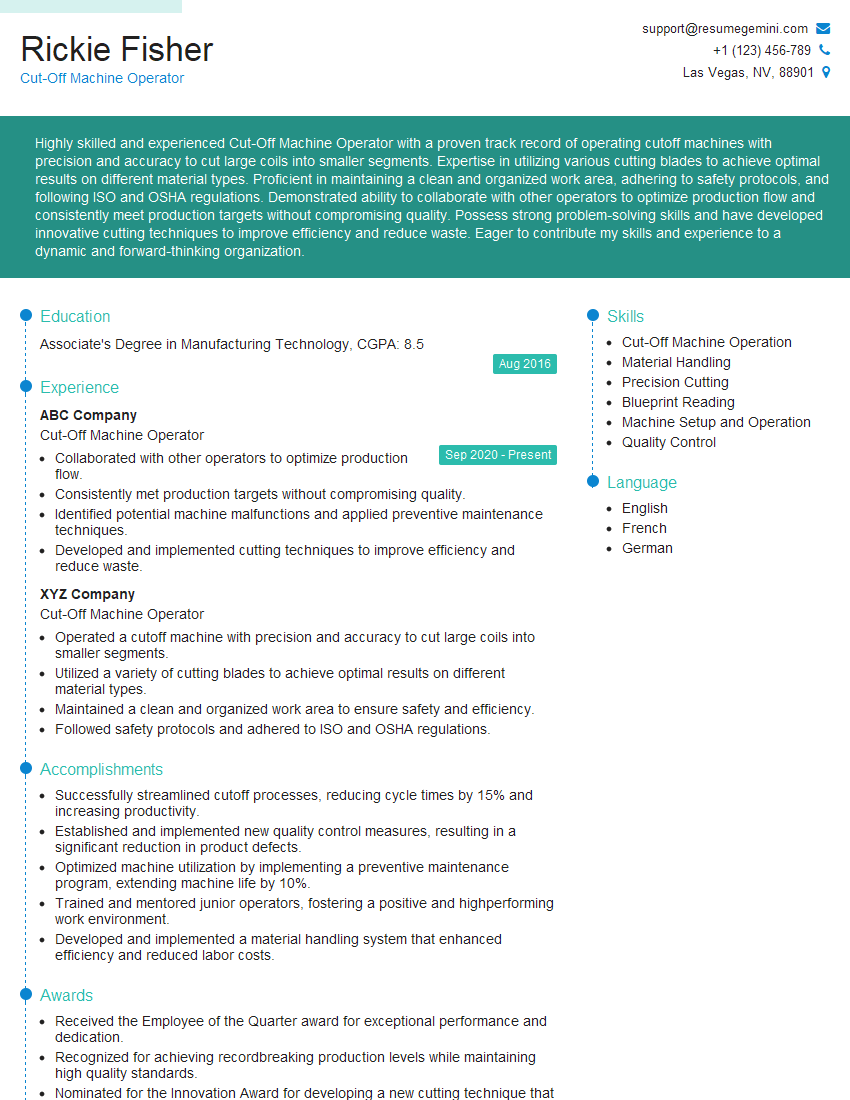

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut-Off Machine Operator

1. Explain the process of setting up a cut-off machine for a specific cutting operation.

- Determine the type of material to be cut and select the appropriate blade.

- Set the machine’s speed and feed rate based on the material and desired cut quality.

- Secure the workpiece in the machine’s vise or clamps.

- Position the blade and adjust the cutting angle according to the specified cut parameters.

- Calibrate the machine’s sensors to ensure accurate cutting.

2. What safety precautions must be taken when operating a cut-off machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Inspect the machine before each use to ensure it is in good working condition.

- Never operate the machine without the safety guards in place.

- Keep hands and clothing away from moving parts.

- Follow established safety procedures for starting, stopping, and cleaning the machine.

3. How do you troubleshoot common problems with cut-off machines?

- Inspect the blade for wear or damage and replace if necessary.

- Check the machine’s speed and feed rate to ensure they are set correctly.

- Confirm that the workpiece is securely clamped and the cutting angle is correct.

- Clean the machine’s sensor to remove any debris that may interfere with operation.

- Refer to the manufacturer’s instructions for specific troubleshooting guidelines.

4. What factors affect the quality of the cut produced by a cut-off machine?

- Sharpness and condition of the blade

- Correct speed and feed rate for the material being cut

- Proper alignment of the cutting angle

- Secure clamping of the workpiece

- Proper maintenance and calibration of the machine

5. Describe the different types of cut-off machines and their applications.

- Abrasive Cut-Off Machines: Use abrasive wheels for cutting hard materials, such as metal and stone.

- Bandsaw Cut-Off Machines: Utilize a continuous band saw for cutting a variety of materials, including metal, wood, and plastic.

- Chop Saw Cut-Off Machines: Feature a rotating blade that swings down to cut materials at a 90-degree angle.

- CNC Cut-Off Machines: Computer-controlled machines that provide precise cuts and high repeatability.

6. Explain the importance of coolant in cut-off operations.

- Lubricates the cutting process, reducing friction and wear on the blade.

- Cools the workpiece and prevents heat buildup, which can affect cut quality and cause workpiece distortion.

- Washes away chips and debris, improving cut accuracy and preventing clogging.

- Enhances the life of the blade and improves overall machine performance.

7. What techniques can be employed to maximize the efficiency of a cut-off operation?

- Use sharp blades and replace them regularly.

- Optimize speed and feed rates to achieve the desired cut quality while minimizing cycle time.

- Secure the workpiece properly to prevent movement during cutting.

- Use coolant to improve cut quality and extend blade life.

- Regularly clean and maintain the machine to ensure optimal performance.

8. Discuss the challenges and potential risks associated with operating a cut-off machine.

- Potential for injury from sharp blades and moving parts

- Exposure to noise, dust, and fumes

- Risk of workpiece flying off if not properly secured

- Machine failure or malfunction

- Importance of adhering to safety precautions and following proper operating procedures

9. How do you maintain a cut-off machine to ensure its optimal performance?

- Clean and lubricate the machine regularly.

- Inspect and replace worn or damaged parts.

- Calibrate the machine’s sensors and adjust as needed.

- Follow the manufacturer’s recommended maintenance schedule.

- Keep the machine’s work area clean and organized.

10. What are some advanced techniques or technologies used in modern cut-off machines?

- Computer numerical control (CNC) for precise and repeatable cuts

- Laser cutting for clean and burr-free cuts

- Waterjet cutting for cutting a wide range of materials with minimal heat input

- Automated workpiece handling systems for improved productivity

- Sensors for monitoring cutting parameters and ensuring quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut-Off Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut-Off Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cut-Off Machine Operators play a crucial role in the manufacturing process by operating and maintaining cut-off machines used to cut materials to specific lengths.

1. Operating Cut-Off Machine

Operate cut-off machines to cut materials into desired lengths and shapes, ensuring precise and clean cuts.

- Set up and adjust cut-off machines according to job specifications.

- Load materials into the machine and secure them properly.

- Monitor the cutting process and make necessary adjustments to ensure accuracy and quality.

2. Machine Maintenance

Perform routine maintenance and troubleshooting to keep cut-off machines in optimal working condition.

- Lubricate and clean machines regularly to prevent wear and tear.

- Inspect machines for any signs of damage or malfunction.

- Troubleshoot and resolve minor issues to minimize downtime.

3. Quality Control

Inspect cut materials to ensure they meet specified dimensions and quality standards.

- Use measuring tools to verify the accuracy of cuts.

- Identify and reject any defective materials.

- Maintain records of quality control inspections.

4. Safety Compliance

Adhere to established safety protocols and regulations while operating cut-off machines.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures before performing maintenance.

- Report any safety concerns or accidents promptly.

Interview Tips

Preparing thoroughly for a Cut-Off Machine Operator interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Role

Take the time to research the company, its products or services, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website to learn about their mission, values, and industry standing.

- Review the job description thoroughly to understand the key responsibilities and qualifications.

2. Emphasize Relevant Skills and Experience

Highlight your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to showcase your impact.

- Provide specific examples of operating and maintaining cut-off machines successfully.

- Share your experience in quality control procedures and ensuring accuracy in cutting materials.

3. Prepare for Technical Questions

Expect technical questions related to cut-off machines and their operation. Practice answering these questions clearly and concisely, demonstrating your technical knowledge.

- Be ready to explain the different types of cut-off machines and their applications.

- Describe the safety protocols you follow while operating cut-off machines.

4. Showcase Safety Awareness

Safety is paramount in this role. Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience with lockout/tagout procedures and other safety measures.

- Explain how you prioritize safety in your daily work routine.

5. Be Enthusiastic and Professional

Maintain a positive and enthusiastic attitude throughout the interview. Be respectful, ask thoughtful questions, and dress professionally.

- Show your eagerness to learn and contribute to the team.

- Ask questions about the company’s culture and opportunities for growth.

Next Step:

Now that you’re armed with the knowledge of Cut-Off Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cut-Off Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini