Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cut Off Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

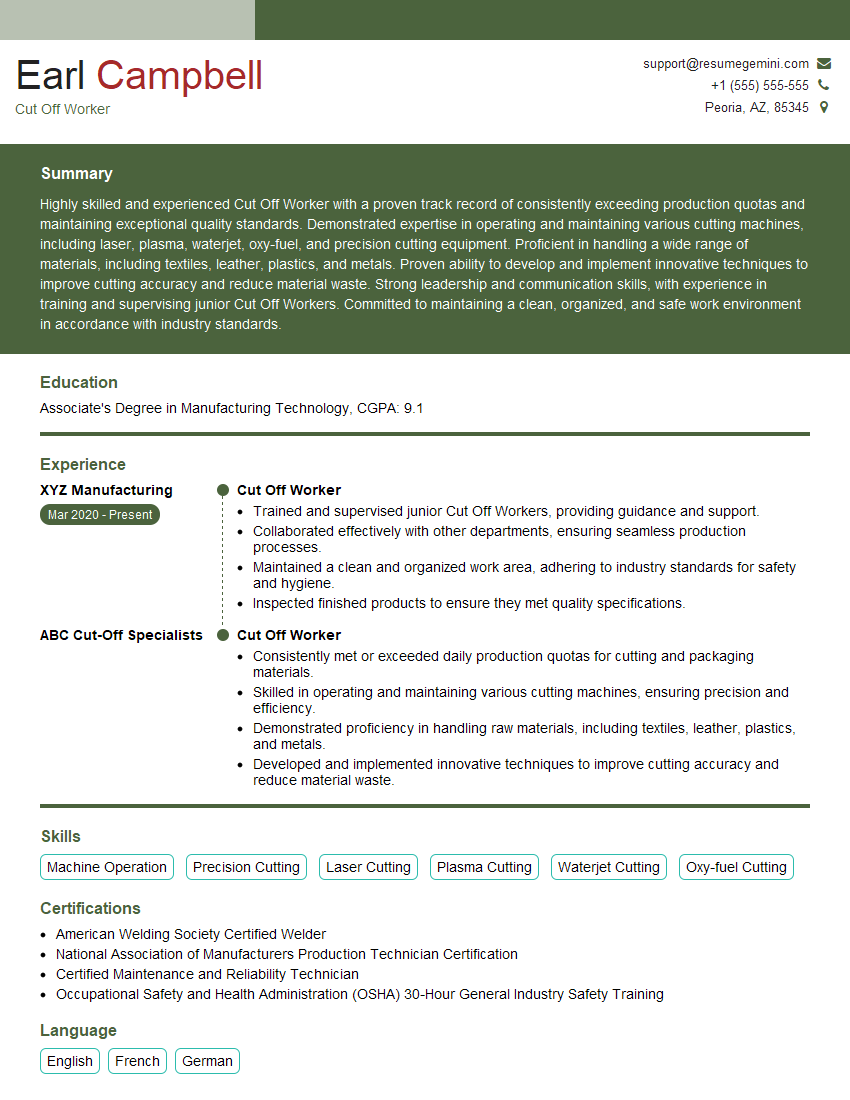

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut Off Worker

1. What are the different techniques used for cutting and trimming fabrics?

There are several techniques used for cutting and trimming fabrics, including:

- Shearing: Using sharp blades to cut fabrics along straight lines or curves.

- Rotary cutting: Using a rotary cutter and mat to cut fabrics precisely.

- Band knife cutting: Using a band knife to cut fabrics in continuous lengths.

- Plasma cutting: Using a plasma torch to cut fabrics with high precision and speed.

- Waterjet cutting: Using a high-pressure waterjet to cut fabrics with complex shapes.

2. What factors should be considered when selecting the appropriate cutting method for a particular fabric?

Factors to consider:

- Fabric type: Different fabrics have different cutting requirements based on their thickness, texture, and grain.

- Cut quality: The desired quality of the cut, such as precision, smoothness, and burr-free edges.

- Production volume: The number of cuts to be made and the required speed of production.

- Equipment availability: The availability of different cutting machines and their capabilities.

- Cost: The cost of the cutting equipment and consumables.

3. Describe the safety precautions that must be followed when operating cutting equipment.

Safety precautions for operating cutting equipment include:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Inspecting equipment regularly and ensuring it is in good working condition.

- Keeping hands clear of cutting blades and moving parts.

- Using sharp blades to reduce the risk of material tearing.

- Following established operating procedures and training.

4. What are the different types of sewing machines used for garment construction, and what are their specific functions?

Types of sewing machines used for garment construction include:

- Lockstitch machines: Used for creating permanent, durable seams.

- Overlock machines: Used for finishing seam edges to prevent fraying.

- Sergers: Similar to overlock machines but with a wider range of stitches and capabilities.

- Coverstitch machines: Used for creating a decorative and stretchy seam on fabrics.

- Buttonhole machines: Used for creating precise and consistent buttonholes.

5. What are the key principles of fabric handling to ensure accurate cutting and sewing?

Key principles of fabric handling include:

- Prewashing and drying: To remove shrinkage and stabilize the fabric.

- Laying out fabric correctly: To ensure accurate pattern placement and cutting.

- Pinning and basting: To hold fabric layers together securely.

- Measuring and marking: To ensure precise cutting and sewing.

- Ironing: To remove wrinkles and set seams.

6. Describe the different types of seams used in garment construction, and when each type is most appropriate.

Types of seams used in garment construction include:

- Plain seam: A basic seam used for joining two pieces of fabric.

- French seam: A more durable seam with enclosed raw edges.

- Flat felled seam: A strong and decorative seam used on garments that require durability.

- Overlock seam: A serged seam used to finish edges and prevent fraying.

- Blind hem: A nearly invisible seam used to hem garments.

7. What are the common defects that can occur during cutting and sewing, and how can they be prevented?

Common defects include:

- Puckering: Caused by uneven fabric tension or improper stitching.

- Waving: Caused by excessive material handling or incorrect cutting.

- Seam slippage: Caused by weak thread or improper seam construction.

- Skipped stitches: Caused by faulty sewing machines, improper threading, or dull needles.

- Fabric tears: Caused by careless handling or sharp cutting blades.

Prevention measures include:

- Ensuring proper tension settings.

- Handling fabrics carefully.

- Using sharp needles and threads.

- Maintaining and calibrating sewing machines regularly.

8. What is the role of quality control in the garment manufacturing process, and how do you ensure consistency in product quality?

Quality control in garment manufacturing involves:

- Inspecting raw materials: To ensure they meet quality standards.

- Monitoring production processes: To identify and correct any deviations.

- Implementing quality control checks: At various stages of production to ensure compliance with specifications.

- Documenting and tracking quality data: To analyze and improve processes.

Consistency in product quality is ensured by:

- Establishing clear quality standards.

- Training employees on quality control procedures.

- Using standardized production methods.

- Regularly calibrating and maintaining equipment.

9. How do you stay up-to-date with advancements in cutting and sewing technologies?

To stay up-to-date with advancements in cutting and sewing technologies, I engage in the following activities:

- Attending industry trade shows and conferences: To learn about new equipment, materials, and techniques.

- Reading industry publications and online resources: To stay informed about the latest developments.

- Networking with other professionals: To share knowledge and gain insights from their experiences.

- Participating in online forums and discussion groups: To engage with the wider industry community.

10. What is your approach to working in a fast-paced environment and meeting production deadlines?

In a fast-paced environment, I adopt the following approach to meet production deadlines:

- Prioritizing tasks: Identifying the most important and urgent tasks to focus on first.

- Time management: Allocating time effectively and avoiding distractions.

- Delegating responsibilities: Assigning tasks to capable team members to distribute the workload.

- Staying organized: Maintaining a clean and efficient work area to minimize wasted time.

- Communicating effectively: Keeping team members informed of progress and any potential delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut Off Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut Off Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Cut Off Worker, you will be primarily responsible for operating a cutting machine to separate different parts of hides or skins. Your responsibilities will include:

1. Setting up and operating cutting machine

You will be responsible for setting up and operating the cutting machine to cut hides or skins into specific shapes and sizes.

2. Inspecting materials before cutting

Before cutting, you will inspect the hides or skins for any defects or damage to ensure the quality of the finished product.

3. Maintaining and cleaning equipment

You will be responsible for maintaining and cleaning the cutting machine and other equipment used in the cut off process to ensure their optimal performance.

4. Following safety procedures

You will be required to adhere to all safety procedures and wear appropriate safety gear while operating the cutting machine to prevent accidents and injuries.

Interview Tips

To ace your interview for a Cut Off Worker position, here are some tips and tricks:

1. Research the company and the role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and the expectations for the position.

2. Practice your answers to common interview questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

3. Highlight your skills and experience

Make sure to highlight your relevant skills and experience in your resume and during the interview. Emphasize your ability to operate cutting machines, inspect materials, and follow safety procedures.

4. Ask questions about the role and the company

At the end of the interview, ask thoughtful questions about the role and the company. This shows that you are engaged and interested in the position.

5. Dress appropriately and arrive on time

Dress professionally and arrive on time for your interview. This demonstrates your respect for the company and the interviewers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cut Off Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!