Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cut-Out Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cut-Out Machine Operator so you can tailor your answers to impress potential employers.

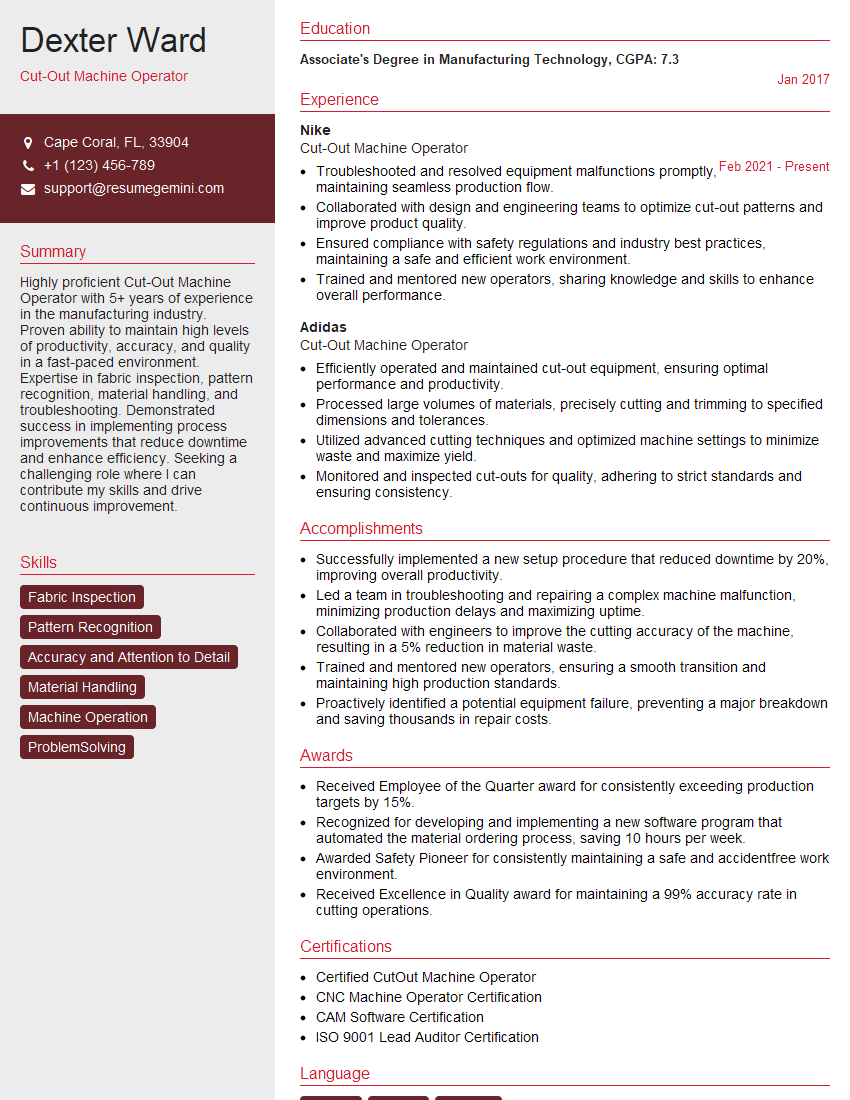

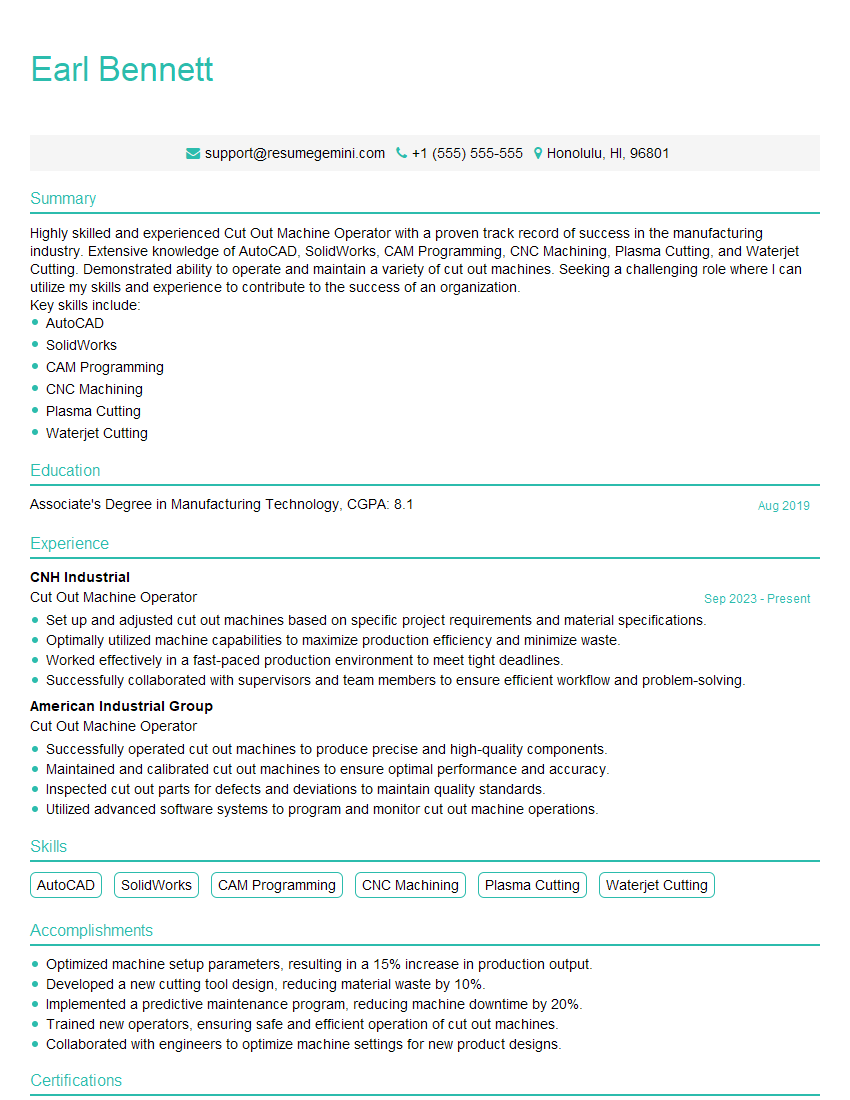

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut-Out Machine Operator

1. Describe the key responsibilities of a Cut-Out Machine Operator?

- Operate cut-out machines to cut out various shapes and sizes of fabric, leather, or other materials.

- Inspect materials for defects and select appropriate cutting tools.

- Set up and adjust machines to ensure accurate and efficient cutting.

- Monitor cutting operations and make adjustments as needed.

- Clean and maintain machines to ensure optimal performance.

2. What are the different types of cut-out machines and their applications?

Manual Cut-Out Machines

- Used for small-scale production and cutting intricate designs.

- Require manual operation and precision.

Semi-Automatic Cut-Out Machines

- Offer increased efficiency and precision compared to manual machines.

- Feature computerized controls and automated functions.

Fully Automatic Cut-Out Machines

- Highly efficient and productive for large-scale production.

- Operate with minimal human intervention and advanced automation.

3. How do you ensure the accuracy of cut-out shapes?

- Use precision cutting tools and regularly calibrate machines.

- Inspect materials for defects and select appropriate cutting parameters.

- Follow established cutting patterns and templates.

- Monitor cutting operations and make adjustments as needed.

4. What safety measures should be followed when operating cut-out machines?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure proper machine guarding and fencing.

- Keep work area clean and free of obstructions.

- Follow established safety protocols and procedures.

5. How do you troubleshoot common issues with cut-out machines?

- Identify and diagnose the problem by observing machine performance and error messages.

- Refer to maintenance manuals and technical documentation for guidance.

- Perform basic troubleshooting steps, such as checking power supply, connections, and settings.

- Contact technical support or a qualified technician for assistance with complex issues.

6. What is the importance of maintaining and cleaning cut-out machines regularly?

- Ensures optimal performance and accuracy of cut-out shapes.

- Extends the machine’s lifespan and reduces downtime.

- Maintains a safe and clean work environment.

- Reduces the risk of machine breakdowns and accidents.

7. Describe the different types of materials that can be cut using cut-out machines and their respective cutting techniques.

- Fabrics: Woven, knitted, and non-woven materials, using techniques like laser cutting, waterjet cutting, or die cutting.

- Leather: Genuine, synthetic, and bonded leather, using techniques like die cutting, laser cutting, or waterjet cutting.

- Paper and Cardboard: Used in packaging and printing, cut using techniques like die cutting, laser cutting, or guillotine cutting.

- Plastics: Flexible and rigid plastics, cut using techniques like laser cutting, waterjet cutting, or CNC routing.

8. How do you optimize cut-out machine settings for different materials and cutting requirements?

- Consult manufacturer’s recommendations and technical manuals.

- Experiment with different settings, such as cutting speed, pressure, and temperature.

- Adjust settings based on material properties, thickness, and desired cut quality.

- Monitor cutting results and make adjustments as needed.

9. What techniques do you use to minimize material waste during cut-out operations?

- Use nesting software to optimize cutting patterns and reduce scrap.

- Plan cutting sequences to maximize material utilization.

- Consider using recycled or remnant materials for less critical parts.

- Explore alternative cutting techniques that minimize material consumption.

10. How do you stay updated with advancements in cut-out machine technology?

- Attend industry trade shows and conferences.

- Read technical journals and publications.

- Connect with manufacturers and suppliers for information on new equipment and technologies.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut-Out Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut-Out Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cut-Out Machine Operators are responsible for the safe and efficient operation of cut-out machines. They work in various industries, such as manufacturing, packaging, printing, and food processing. Their responsibilities include:

1. Machine Operation

Operate cut-out machines that utilize various cutting tools, like blades, dies, and lasers, to cut materials into specific shapes and sizes.

- Set up and calibrate machines following established procedures.

- Load and unload materials to be cut.

2. Quality Control

Inspect cut-out pieces to ensure they meet specifications and quality standards.

- Identify and correct any defects or errors in the cutting process.

- Make adjustments to the machine or cutting tools as needed.

3. Maintenance

Perform basic maintenance on cut-out machines, including cleaning and lubricating components.

- Report any major issues or repairs to supervisors.

- Ensure the workstation is kept clean and organized.

4. Safety

Follow all safety procedures and wear appropriate personal protective equipment (PPE).

- Operate machines only when authorized and trained.

- Handle materials and tools safely.

Interview Tips

Interviews can be nerve-racking but being prepared and practicing is the key. Here are some tips to help you ace your interview:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Cut-Out Machine Operator.

- Visit the company’s website to learn about their products, services, and mission.

- Check out the company’s social media pages to get a sense of their culture and values.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked. By preparing your answers, you can feel more confident and composed during the interview.

- Tell me about yourself.

- Why are you interested in this role?

- What are your strengths and weaknesses?

- What is your experience with cut-out machines?

- How do you handle working in a fast-paced environment?

3. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time. This shows the interviewer that you are serious about the role and that you respect their time.

- Wear clean, pressed clothing that fits well.

- Avoid wearing strong scents or jewelry.

- Plan your route and allow yourself plenty of time to get to the interview.

4. Be Enthusiastic and Engaged

Show the interviewer that you are enthusiastic about the role and the company. Be engaged in the conversation and ask questions to show that you are interested. Interviewers look for candidates passionate about work and the company’s goals.

- Make eye contact with the interviewer and smile.

- Ask thoughtful questions about the role and the company.

- Thank the interviewer for their time at the end of the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cut-Out Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.