Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cut Out Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

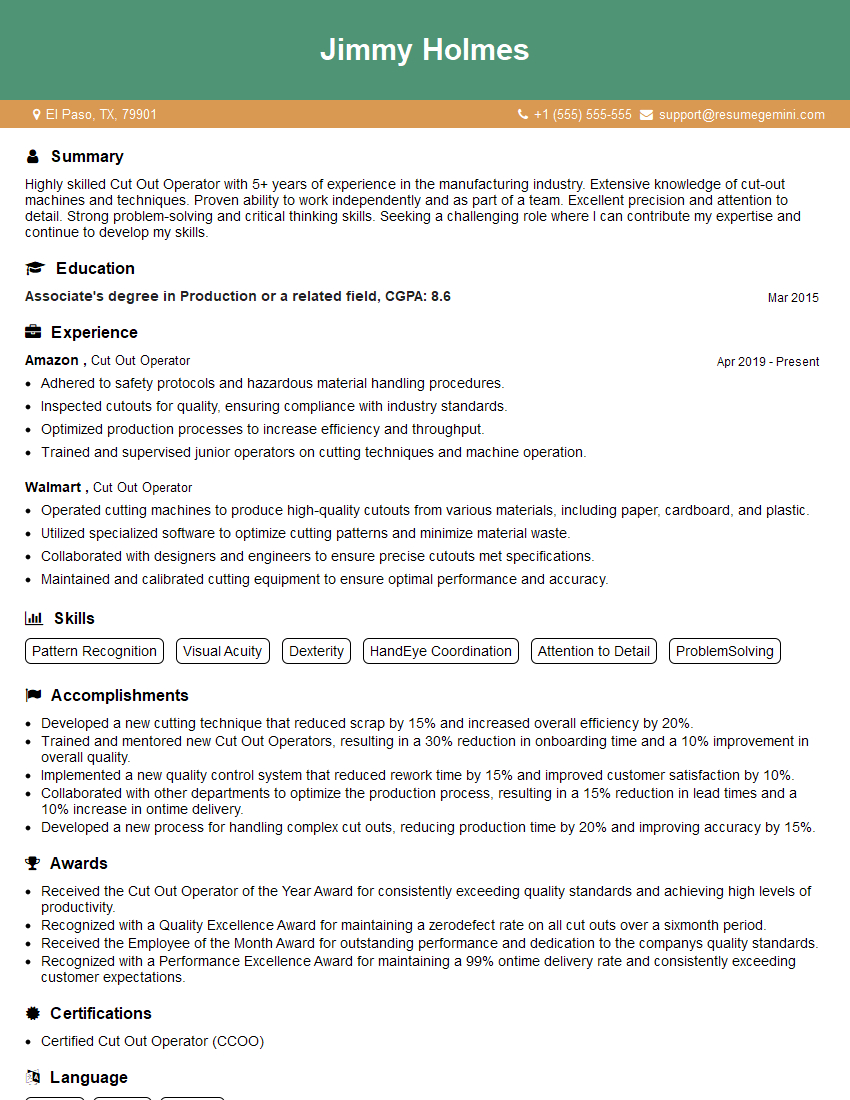

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut Out Operator

1. What are the different types of cutting machines used in a garment factory?

There are several types of cutting machines used in a garment factory, including:

- Band knife cutting machine: Used for cutting multiple layers of fabric simultaneously with a high degree of accuracy.

- Straight knife cutting machine: Used for cutting single layers of fabric or delicate materials with a sharp, straight blade.

- Die cutting machine: Used for cutting intricate shapes and patterns from fabric using a die or mold.

- Laser cutting machine: Uses a laser to cut fabric with precision and minimal fraying.

- Water jet cutting machine: Uses a high-pressure jet of water to cut fabric, resulting in smooth and burr-free edges.

2. How do you ensure the accuracy and precision of your cutting operations?

Calibration and Maintenance

- Regularly calibrate cutting machines using precision measuring tools to ensure accuracy.

- Perform routine maintenance to keep machines in optimal condition and prevent deviations.

Material Handling

- Handle fabric carefully to avoid stretching or distorting it before cutting.

- Use appropriate cutting surfaces and templates to ensure proper alignment.

Quality Control

- Inspect cut pieces thoroughly to ensure they meet specifications.

- Use quality control tools like rulers or templates to verify dimensions and shapes.

3. What are some common defects that can occur during cutting operations and how do you prevent them?

- Inaccurate cutting: Caused by incorrect machine calibration or improper material handling. Prevention: Regular calibration, precise measurement, and careful fabric handling.

- Fraying edges: Occurs when the fabric is not cut cleanly. Prevention: Use sharp blades, maintain proper cutting pressure, and avoid pulling or stretching the fabric.

- Notching and skipping: Irregularities in cutting that result in missing or incomplete cuts. Prevention: Ensure proper blade sharpness, adjust cutting speed, and inspect the cutting surface for any wear or damage.

- Uneven layers: When multiple layers of fabric are not cut evenly. Prevention: Use proper pressure and alignment tools, and inspect the cutting surface for any unevenness.

4. How do you handle and store different types of fabrics during cutting operations?

- Woven fabrics: Stored flat and protected from moisture to prevent wrinkles or shrinkage.

- Knitted fabrics: Folded loosely to avoid stretching or distorting the fabric.

- Delicate fabrics: Handled with care to prevent snags or tears. Stored on soft surfaces like foam or tissue paper.

- Embroidered or printed fabrics: Protected from direct sunlight and moisture to preserve the designs.

5. What are the safety precautions you follow when operating cutting machines?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure the cutting area is well-lit and has proper ventilation.

- Keep the cutting machine clean and free of debris.

- Never reach over or under a cutting machine while it is in operation.

- Follow all manufacturer’s instructions and safety protocols.

6. How do you optimize cutting operations to minimize waste and maximize efficiency?

- Efficient layout: Plan the cutting area to minimize movement and optimize workflow.

- Material utilization: Utilize nesting software or manual techniques to maximize fabric usage and reduce waste.

- Sharpen blades regularly: Maintain sharp blades to ensure clean cuts and reduce fabric distortion.

- Proper maintenance: Regularly service and calibrate cutting machines to prevent breakdowns and ensure optimal performance.

- Training and supervision: Train operators thoroughly and supervise them to ensure proper techniques and prevent errors.

7. What is the role of a spread table in the cutting process?

- Fabric preparation: Used to spread and align multiple layers of fabric before cutting.

- Accuracy: Ensures that fabrics are evenly spread and aligned, leading to more precise cutting.

- Efficiency: Facilitates faster and more efficient cutting by keeping the fabric in place.

- Safety: Provides a stable surface for cutting, minimizing the risk of accidents.

8. How do you handle and dispose of fabric scraps generated during cutting operations?

- Sorting: Categorize and sort fabric scraps based on type, color, and size.

- Reuse: Utilize scraps for smaller items, such as patches, trims, or accessories.

- Recycling: Partner with recycling facilities to donate or sell fabric scraps for reuse in other industries.

- Responsible disposal: Adhere to environmental regulations and dispose of scraps in landfills or incinerators in an environmentally friendly manner.

9. What are the different types of cutting techniques used for special applications in garment manufacturing?

- Pinked edge cutting: Creates decorative zigzag edges to prevent fraying on fabrics like chiffon.

- Slitting: Cuts narrow strips or slits into fabrics for details like buttonholes or pleats.

- Notching: Small cuts made at specific points to guide seam allowances or create design details.

- Flange cutting: Used for cutting curved or intricate shapes with smooth and precise edges.

10. How do you keep up with the latest advancements in cutting technology and techniques?

- Attend industry events: Participate in trade shows and conferences to stay informed about new technologies and best practices.

- Read industry publications: Subscribe to magazines, journals, and online resources to access cutting-edge information.

- Seek training opportunities: Attend workshops or courses offered by manufacturers or industry experts to enhance skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut Out Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut Out Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cut Out Operators are responsible for ensuring the accuracy and quality of cut-outs in a variety of settings, including printing, packaging, and manufacturing.

1. Inspect Materials and Equipment

Before beginning any work, Cut Out Operators must inspect the materials and equipment they will be using to ensure that they are in good condition. This includes checking the sharpness of blades, the accuracy of cutting tools, and the quality of the materials being cut.

- Inspect materials for defects, such as tears, stains, or wrinkles.

- Check the accuracy of cutting tools and ensure that they are sharp.

- Test the equipment to make sure that it is functioning properly.

2. Position and Cut Materials

Once the materials and equipment have been inspected, Cut Out Operators must position the materials and cut them according to the specified dimensions. This requires precision and accuracy, as even a small mistake can result in a defective product.

- Position the materials on the cutting table.

- Use a cutting tool to cut the materials according to the specified dimensions.

- Remove the cut pieces from the table.

3. Inspect Cut-Outs

After the materials have been cut, Cut Out Operators must inspect them to ensure that they meet the required specifications. This includes checking the accuracy of the cuts, the quality of the edges, and the overall appearance of the cut-outs.

- Inspect the cut-outs for accuracy, quality, and appearance.

- Identify any defects and take corrective action.

- Approve or reject the cut-outs.

4. Maintain Equipment and Work Area

Cut Out Operators are responsible for maintaining their equipment and work area. This includes cleaning and lubricating the equipment, as well as keeping the work area clean and organized. This helps to ensure that the equipment is operating properly and that the work area is safe.

- Clean and lubricate the equipment.

- Keep the work area clean and organized.

- Follow safety procedures.

Interview Tips

Interviewing for a Cut Out Operator position can be a nerve-wracking experience. However, by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, social media pages, and Glassdoor reviews. You can also learn more about the position by reading the job description and talking to people who work in the industry.

2. Prepare Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” You can prepare your answers to these questions ahead of time so that you can deliver them confidently and concisely. You can also practice answering these questions with a friend or family member.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time. You should also bring a copy of your resume and any other relevant materials.

4. Be Enthusiastic and Positive

The interviewer wants to see that you are enthusiastic about the position and that you are a positive person. Be sure to smile, make eye contact, and speak in a clear and concise voice. You should also avoid negative body language, such as crossing your arms or slouching.

Next Step:

Now that you’re armed with the knowledge of Cut Out Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cut Out Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini