Feeling lost in a sea of interview questions? Landed that dream interview for Cut Tobacco Bulker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cut Tobacco Bulker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

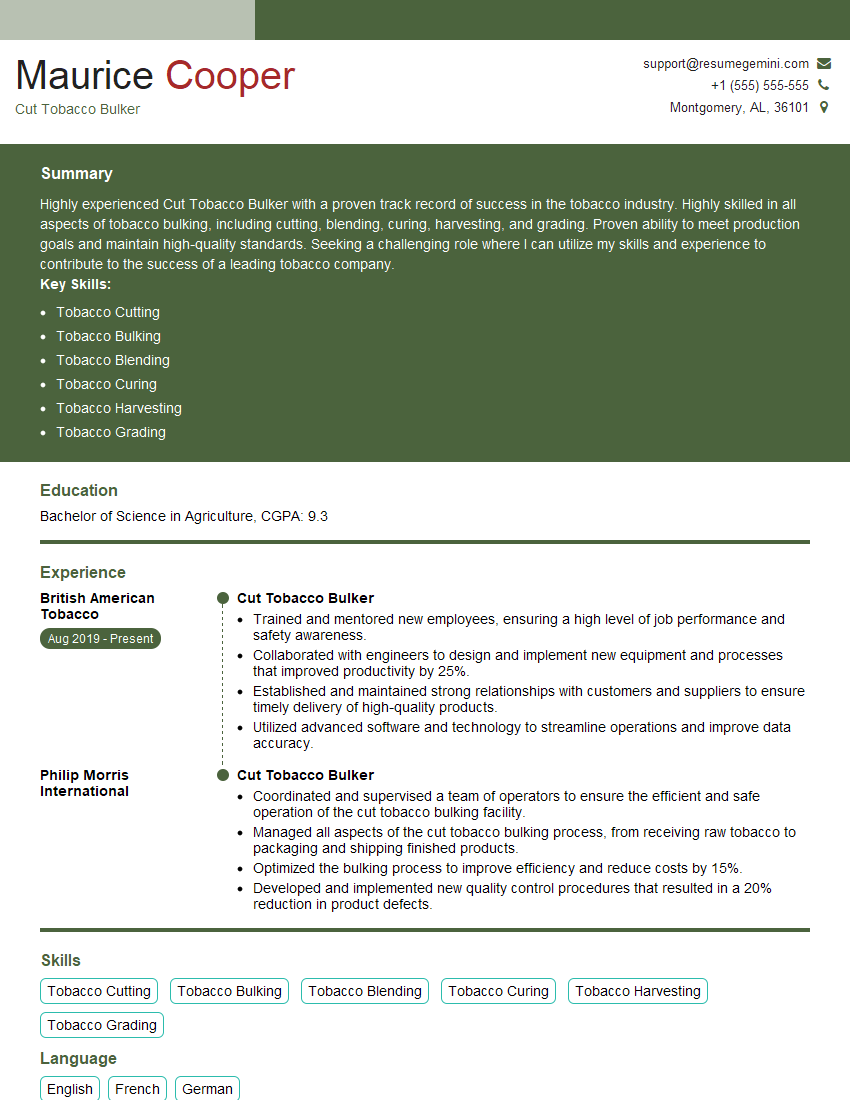

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cut Tobacco Bulker

1. Describe the key responsibilities of a Cut Tobacco Bulker?

- Operate and maintain tobacco bulking machines to blend and package cut tobacco.

- Monitor machine performance, make adjustments, and troubleshoot problems.

- Ensure product quality by adhering to strict standards and specifications.

- Maintain a clean and organized work area, following safety protocols.

2. What are the different types of tobacco bulking machines, and how do they operate?

- These machines process large volumes of tobacco at a fast rate.

- They feature a horizontal conveyor belt that transports tobacco through a series of rollers, which compress and blend the leaves.

- Smaller and slower than horizontal machines, suitable for smaller batches.

- Tobacco is fed into a vertical chamber and compressed using rollers or reciprocating rams.

Horizontal Bulking Machines

Vertical Bulking Machines

3. Explain the importance of moisture content in cut tobacco and how it affects the bulking process?

- Moisture content significantly impacts the bulking process.

- Optimal moisture levels ensure smooth blending, uniform density, and proper packaging.

- Tobacco with high moisture content can lead to clumping and poor quality, while insufficient moisture can result in breakage and dust formation.

4. How do you troubleshoot common problems encountered during the tobacco bulking process?

- Identify the problem by observing machine performance, product quality, or operational data.

- Check for mechanical issues such as belt malfunctions, roller damage, or conveyor blockages.

- Monitor temperature, pressure, and moisture sensors for any abnormalities.

- Adjust machine settings, clean components, or replace faulty parts as needed.

5. What are the safety precautions you must adhere to when operating tobacco bulking machines?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and dust masks.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Keep machines clean and free of dust and tobacco accumulation.

- Monitor for potential fire hazards and have extinguishers readily available.

6. Explain the role of quality control in the cut tobacco bulking process?

- Ensuring that the bulked tobacco meets customer specifications for moisture content, density, cut size, and blend consistency.

- Conducting regular product inspections, testing, and sampling.

- Identifying and addressing any deviations from quality standards.

- Maintaining documentation to trace and track batches for traceability.

7. Describe the maintenance procedures you perform to keep tobacco bulking machines in optimal condition?

- Routine cleaning to remove dust and tobacco accumulation.

- Regular lubrication of moving parts to prevent wear and tear.

- Inspection of belts, rollers, and other critical components for damage or wear.

- Planned maintenance schedules to address potential issues before they occur.

8. How do you manage production targets while ensuring product quality and safety standards?

- Prioritize tasks and allocate resources effectively.

- Monitor machine performance and product quality throughout the bulking process.

- Make adjustments to machine settings or work processes as needed to optimize output.

- Communicate with supervisors and other team members to ensure seamless operations.

9. Describe your experience in optimizing tobacco bulking processes to improve efficiency and reduce costs?

- Analyzed machine performance data and identified areas for improvement.

- Implemented new techniques or technologies to streamline operations.

- Reduced waste and downtime through effective maintenance and troubleshooting.

- Collaborated with other departments to optimize supply chain and production workflows.

10. What are the latest advancements in tobacco bulking technology, and how do they benefit the industry?

- Automated systems for monitoring and controlling bulking parameters.

- Advanced sensors for real-time quality control and traceability.

- Robotics for handling and packaging tobacco.

- These advancements enhance efficiency, reduce labor requirements, and improve product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cut Tobacco Bulker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cut Tobacco Bulker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Cut Tobacco Bulker, the incumbent’s primary responsibility is to operate and maintain tobacco bulking machines. This involves a range of tasks, including:

1. Machine Operation

• Operate tobacco bulking machines to homogenize and blend various types of cut tobacco.

• Monitor machine settings and make adjustments as needed to ensure optimal performance and product quality.

• Troubleshoot and resolve any operational issues related to the bulking machines.

2. Quality Control

• Inspect raw materials and finished products to ensure they meet quality standards.

• Conduct regular checks on the bulking process to identify and correct any deviations from established procedures.

• Maintain detailed records of all quality control checks and inspections.

3. Maintenance and Repair

• Perform routine maintenance and cleaning of bulking machines to ensure their proper functioning.

• Identify and repair minor mechanical or electrical issues with the machines.

• Collaborate with maintenance personnel to resolve complex technical problems.

4. Safety Compliance

• Adhere to all established safety protocols and regulations related to the operation and maintenance of tobacco bulking machines.

• Use appropriate personal protective equipment (PPE) to minimize the risk of injury.

• Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview is key to making a positive impression and showcasing your qualifications for the Cut Tobacco Bulker position. Here are some tips to help you ace the interview:

1. Research the Company and the Role

• Familiarize yourself with the company’s history, products, and industry standing.

• Review the job description carefully and identify the key skills and experience required for the position.

2. Practice Your Answers

• Anticipate common interview questions and prepare thoughtful and concise answers.

• Practice delivering your answers aloud to gain confidence and improve your articulation.

3. Highlight Relevant Skills and Experience

• Quantify your accomplishments and provide specific examples that demonstrate your technical abilities.

• Emphasize your experience in operating and maintaining tobacco bulking machines.

4. Show Enthusiasm and Passion

• Express your genuine interest in the position and the tobacco industry.

• Convey your willingness to learn and grow in the role.

5. Ask Informed Questions

• Prepare thoughtful questions that show you are engaged and interested in the company and the position.

• Ask about the company’s plans for the future, the growth opportunities within the role, and the company’s commitment to quality and safety.

Next Step:

Now that you’re armed with the knowledge of Cut Tobacco Bulker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cut Tobacco Bulker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini