Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cutter Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

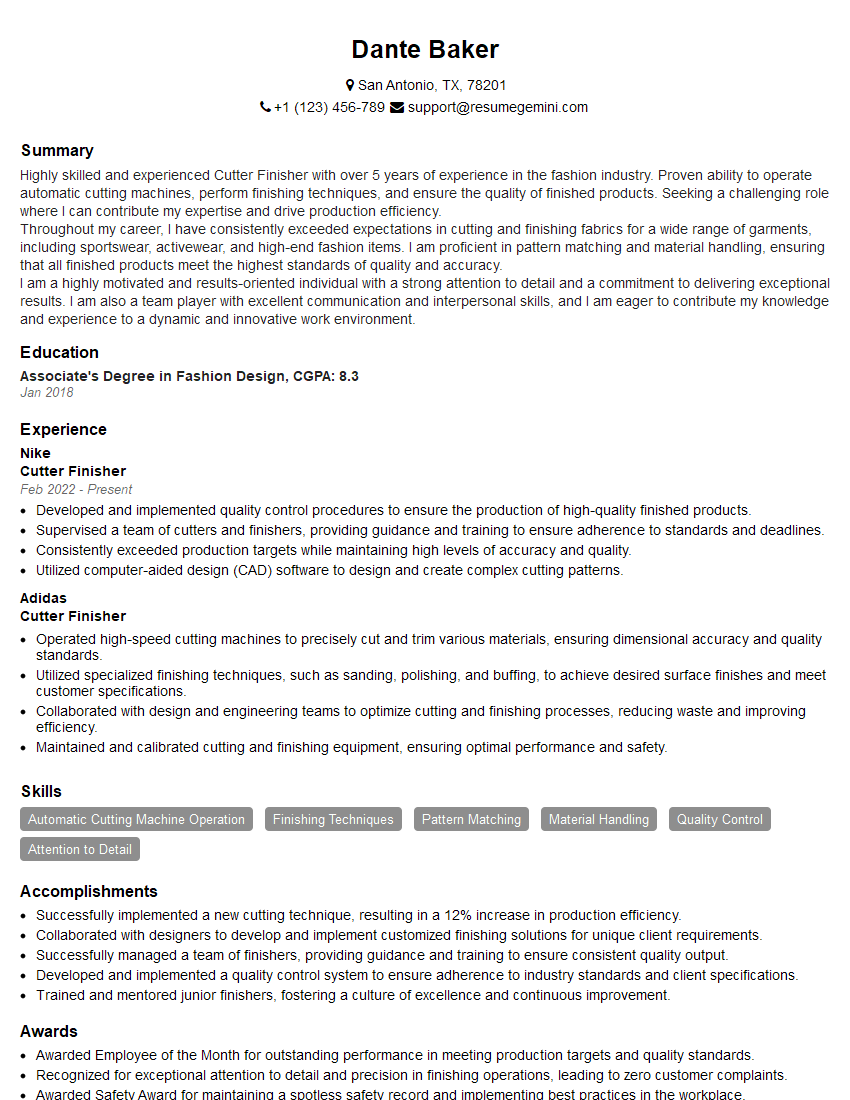

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter Finisher

1. What is the standard process for cutting and finishing a variety of materials?

The standard process for cutting and finishing a variety of materials typically involves the following steps:

- Selecting the appropriate cutting tool and material

- Preparing the material for cutting, including securing it and marking the cutting lines

- Cutting the material using a variety of techniques, such as hand cutting, machine cutting, or laser cutting

- Finishing the cut edge to remove any burrs or imperfections by sanding, filing, or polishing

- Inspecting the finished product to ensure it meets the required specifications

2. What are the different types of cutting tools used in the industry?

Hand Cutting Tools

- Scissors

- Knives

- Shears

Machine Cutting Tools

- Saws

- Drills

- Routers

Laser Cutting Tools

- Laser cutters

- Plasma cutters

- Water jet cutters

3. How do you select the appropriate cutting tool for a specific material?

To select the appropriate cutting tool for a specific material, consider the following factors:

- The thickness and hardness of the material

- The desired cut quality

- The available cutting tools and equipment

- The cost and time constraints

4. What are the common problems encountered during cutting and finishing and how do you troubleshoot them?

Common problems encountered during cutting and finishing include:

- Material distortion or warping

- Burrs or imperfections on the cut edge

- Tool breakage or malfunction

- Inaccurate or inconsistent cutting

Troubleshooting involves identifying the root cause of the problem and implementing corrective actions, such as:

- Adjusting the cutting parameters

- Selecting a different cutting tool or material

- Improving the material handling and preparation

- Performing regular tool maintenance

5. What safety precautions should be taken when operating cutting and finishing equipment?

When operating cutting and finishing equipment, it is crucial to follow safety precautions to prevent accidents and injuries:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs

- Ensure the equipment is properly installed, maintained, and calibrated

- Follow the manufacturer’s operating instructions and safety guidelines

- Keep the work area clean and free of debris

- Never operate equipment while under the influence of drugs or alcohol

6. How do you measure and ensure the accuracy of the finished product?

To measure and ensure the accuracy of the finished product:

- Use precision measuring tools, such as calipers, micrometers, or measuring tapes

- Compare the measurements to the specified tolerances and dimensions

- Make any necessary adjustments to the cutting or finishing process to achieve the desired accuracy

7. How do you maintain and troubleshoot cutting and finishing equipment?

To maintain and troubleshoot cutting and finishing equipment:

- Follow the manufacturer’s maintenance schedule for regular cleaning, lubrication, and adjustments

- Inspect the equipment for any signs of wear or damage, and replace worn or damaged parts as needed

- Troubleshoot any problems according to the manufacturer’s instructions or by consulting with a qualified technician

8. How do you stay updated on the latest advances in cutting and finishing technologies?

To stay updated on the latest advances in cutting and finishing technologies:

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Network with other professionals in the field

- Participate in training and certification programs

9. How do you prioritize and manage multiple cutting and finishing projects?

To prioritize and manage multiple cutting and finishing projects:

- Develop a work plan that outlines the tasks, deadlines, and dependencies

- Set priorities based on the project’s importance, urgency, and customer requirements

- Allocate resources and assign responsibilities to team members

- Monitor the progress of each project and make adjustments as needed

- Communicate regularly with stakeholders to keep them informed of the project status

10. How do you handle tight deadlines and pressure situations in the workplace?

To handle tight deadlines and pressure situations in the workplace:

- Prioritize tasks and focus on completing the most important ones first

- Communicate with colleagues and supervisors to ensure everyone is aware of the deadlines

- Delegate tasks to others when possible

- Take breaks when needed to avoid burnout

- Stay positive and maintain a sense of humor

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cutter Finisher plays a crucial role in the garment production process, with key responsibilities that include:1. Cutting and Finishing Textiles:

- Operate cutting machines to cut fabric according to patterns.

- Trim and finish cut fabric edges to prepare them for sewing.

- Inspect cut and finished fabric for defects and ensure quality.

2. Fabric Handling:

- Load, unload, and handle fabrics throughout the cutting and finishing process.

- Maintain a clean and organized work area to prevent fabric damage.

- Follow safety protocols for handling heavy fabrics and cutting equipment.

3. Machine Maintenance and Troubleshooting:

- Perform routine maintenance and cleaning of cutting and finishing machines.

- Monitor machine performance and troubleshoot minor issues.

- Report any major mechanical problems to supervisors for timely repair.

4. Production Planning and Execution:

- Plan and prepare cutting and finishing schedules based on production orders.

- Coordinate with other departments to ensure a smooth production flow.

- Meet production deadlines and quality standards.

Interview Tips

To ace the interview for the Cutter Finisher position, candidates should:1. Research the Company and Industry:

- Familiarize yourself with the company’s background, products, and market position.

- Learn about the latest trends and technologies in the garment production industry.

- This knowledge shows that you are genuinely interested in the opportunity and have done your homework.

2. Showcase Relevant Experience and Skills:

- Highlight your prior experience in cutting and finishing fabrics.

- Provide specific examples of your ability to handle various fabrics, operate cutting machines, and ensure quality.

- Emphasize your attention to detail and commitment to accuracy.

3. Prepare for Common Interview Questions:

- Practice answering questions related to your technical skills, production planning, and problem-solving abilities.

- Be prepared to explain your understanding of the Cutter Finisher’s role and how your qualifications align with the requirements.

- Prepare examples of challenging situations you faced in previous roles and how you successfully resolved them.

4. Demonstrate Your Work Ethic and Team Spirit:

- Emphasize your strong work ethic, commitment to meeting deadlines, and ability to work under pressure.

- Highlight your experience working in a team environment and collaborating with other production staff.

- Express your willingness to learn and contribute to the team’s success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cutter Finisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cutter Finisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.