Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cutter Inspector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

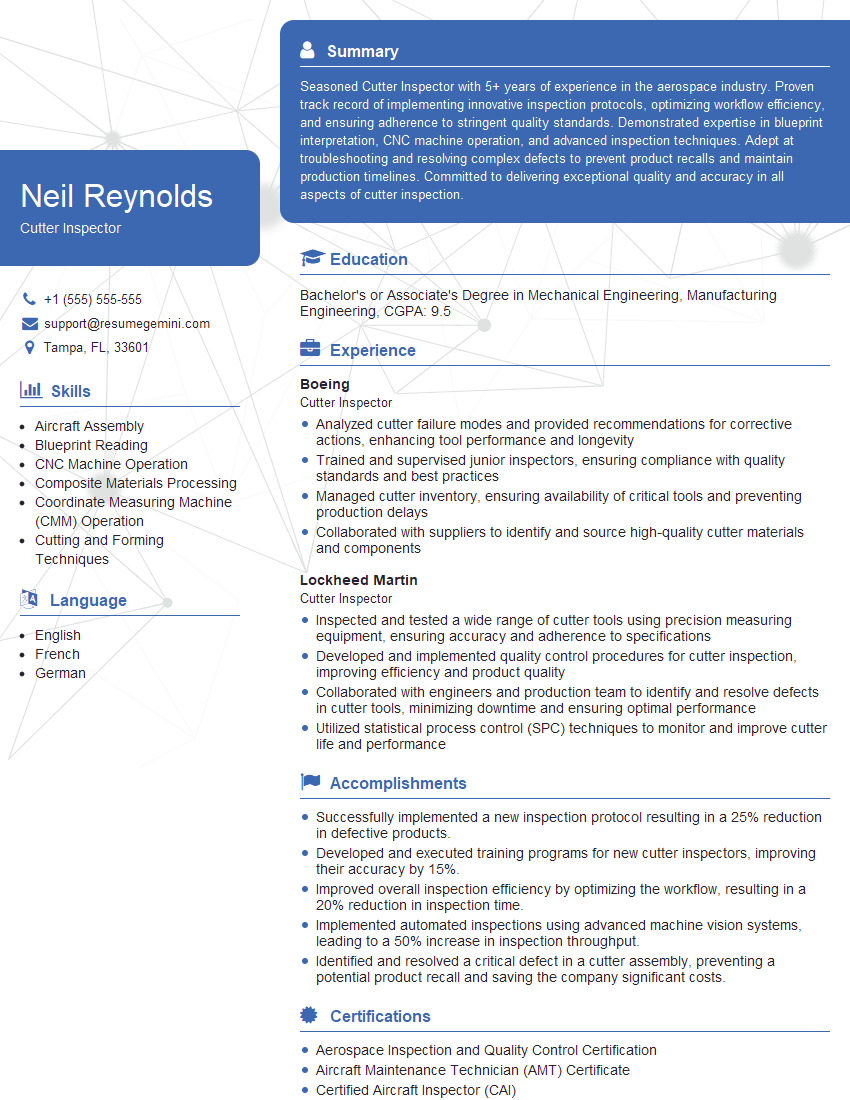

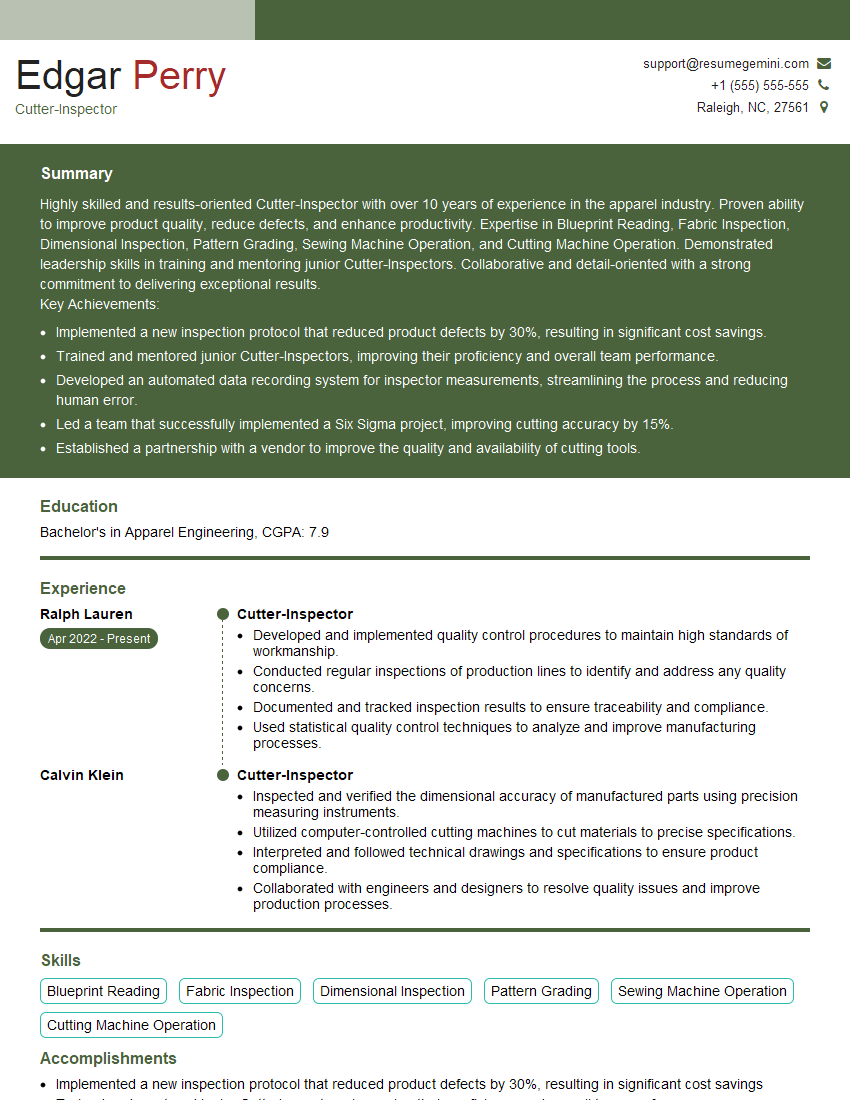

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter Inspector

1. What gauges do you use regularly for cutter inspection?

Commonly used cutter inspection gauges include:

- Dial gauges

- Micrometers

- Calipers

- Thread gauges

- Optical comparators

2. Describe the procedure you follow to inspect a new cutter.

Visual Inspection

- Examine for any visible defects, such as cracks or chips.

- Check for proper finish and surface condition.

Dimensional Inspection

- Measure overall dimensions using calipers or micrometers.

- Verify critical dimensions, such as cutting edge angle, tooth pitch, and flute count.

Functional Inspection

- Test the cutter on a sample workpiece to evaluate its cutting performance.

- Inspect the workpiece for any imperfections or deviations from desired specifications.

3. How do you determine if a cutter is worn out and needs to be replaced?

- Excessive wear on cutting edges

- Reduced cutting efficiency

- Increased tool vibration

- Chipped or damaged teeth

- Deviations from original specifications

4. What is the importance of proper cutter sharpening?

- Maintains optimal cutting performance

- Extends cutter life

- Reduces wear and tear on the machine

- Improves workpiece quality

5. Describe the steps involved in sharpening a milling cutter.

- Select the appropriate grinding wheel

- Secure the cutter in the grinding machine

- Grind each tooth individually

- Maintain proper grinding angle and pressure

- Check the cutter for sharpness and balance.

6. What is the difference between a positive and negative rake angle on a cutter?

- Positive rake angle: The cutting edge is inclined away from the direction of cutting, reducing cutting forces and providing a smoother finish.

- Negative rake angle: The cutting edge is inclined towards the direction of cutting, increasing cutting forces but providing a stronger and more durable cutting edge.

7. How do you measure the effective rake angle of a cutter?

- Tilt the cutter by 90 degrees and measure the angle between the cutting edge and the perpendicular plane

- Use a protractor or a dedicated rake angle measuring tool

8. What are the common materials used for cutter bodies?

- High-speed steel (HSS)

- Carbide

- Ceramics

- Diamond

9. How does coolant affect the performance of a cutter?

- Reduces cutting forces and temperature

- Extends cutter life

- Improves surface finish

- May require specific types of coolant for optimal performance

10. What is the purpose of a cutter arbor?

- Connects the cutter to the machine spindle

- Transmits rotation and torque to the cutter

- Provides the necessary support and rigidity during cutting

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutter Inspectors are responsible for examining and inspecting cutting tools to ensure they meet required standards of quality and precision. Their key job responsibilities include:

1. Tool Inspection

Inspecting cutters for defects, wear, and damage using precision measuring instruments.

- Verifying dimensions and tolerances against specifications.

- Checking for proper cutting edges, sharpness, and surface finish.

2. Quality Control

Ensuring cutters meet company standards and customer requirements.

- Maintaining inspection records and documenting findings.

- Identifying and reporting any deviations from specifications.

3. Tool Repair and Maintenance

Performing minor repairs and maintenance on cutters to ensure optimal performance.

- Replacing worn or damaged components.

- Cleaning and lubricating cutters as needed.

4. Data Analysis

Analyzing inspection data to identify trends and improve inspection processes.

- Monitoring cutter performance over time.

- Recommending adjustments to inspection procedures.

Interview Tips

Preparing for an interview for a Cutter Inspector position requires thorough research and practice. Here are some interview tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s business, industry, and specific role requirements.

- Visit the company website and read industry publications.

- Identify the key responsibilities and skills required for the position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in cutter inspection, quality control, and tool repair.

- Provide specific examples of projects where you demonstrated these skills.

- Quantify your accomplishments whenever possible.

3. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivations.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Practice answering questions in a clear and concise manner.

4. Ask Thoughtful Questions

Asking informed questions shows your interest and engagement in the position and the company.

- Prepare questions about the company’s growth plans, industry trends, and your potential contributions.

- Avoid asking questions that can be easily answered by reading the company website.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutter Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!