Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cutter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cutter so you can tailor your answers to impress potential employers.

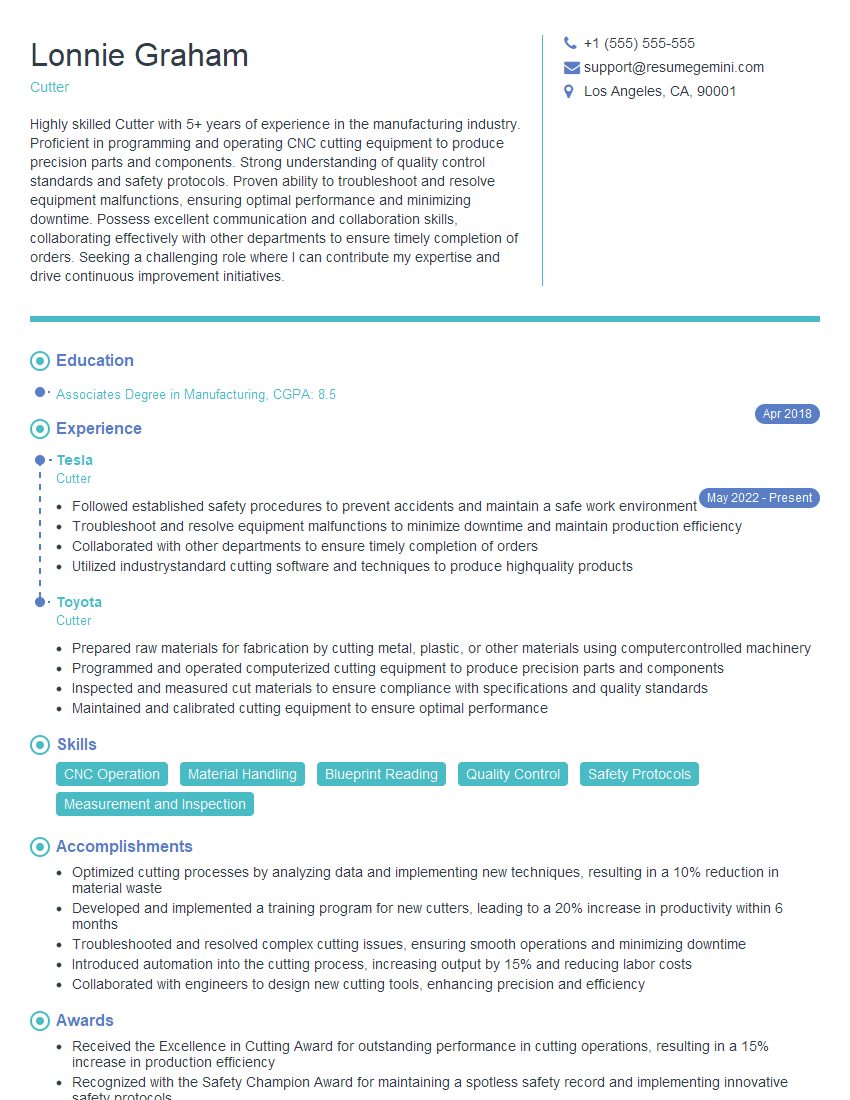

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter

1. What are the key differences between a straight knife and a draw knife?

- A straight knife has a straight blade that is used for cutting straight lines.

- A draw knife has a curved blade that is used for cutting curves and shaping wood.

2. What are the different types of chisels?

Bench Chisels

- Paring chisels are used for delicate work, such as carving.

- Mortise chisels are used for cutting mortises, which are square or rectangular holes in wood.

- Butt chisels are used for cutting joints, such as mortise and tenon joints.

Socket Chisels

- Socket chisels are similar to bench chisels, but they have a socket that fits over the handle.

- This makes them more durable and less likely to break.

3. What are the different types of saws?

- Hand saws are used for cutting wood by hand.

- Power saws are used for cutting wood using a motor.

- There are many different types of saws, each with its own purpose.

- Some of the most common types of saws include:

- Circular saws

- Jigsaws

- Miter saws

- Table saws

4. What are the different types of joinery?

- Joinery is the process of joining pieces of wood together.

- There are many different types of joinery, each with its own purpose.

- Some of the most common types of joinery include:

- Butt joints

- Edge joints

- Miter joints

- Mortise and tenon joints

5. What are the different types of wood finishes?

- Wood finishes are used to protect wood from the elements and to improve its appearance.

- There are many different types of wood finishes, each with its own purpose.

- Some of the most common types of wood finishes include:

- Oil finishes

- Varnish finishes

- Polyurethane finishes

- Shellac finishes

6. What are the different types of woodworking tools?

- There are many different types of woodworking tools, each with its own purpose.

- Some of the most common types of woodworking tools include:

- Cutting tools

- Shaping tools

- Measuring tools

- Clamping tools

- Finishing tools

7. What are the safety precautions that should be taken when using woodworking tools?

- Woodworking tools can be dangerous if they are not used properly.

- It is important to take the following safety precautions when using woodworking tools:

- Wear appropriate safety gear, such as safety glasses, earplugs, and a dust mask.

- Keep your work area clean and free of clutter.

- Inspect your tools before each use and make sure they are in good working condition.

- Follow the manufacturer’s instructions for using each tool.

- Never use a tool that you are not familiar with.

- If you are unsure about how to use a tool, ask for help from a qualified professional.

8. What are the different types of wood joints?

- Wood joints are used to connect pieces of wood together.

- There are many different types of wood joints, each with its own purpose.

- Some of the most common types of wood joints include:

- Butt joints

- Edge joints

- Miter joints

- Mortise and tenon joints

- Dovetail joints

9. What are the different types of woodworking machines?

- Woodworking machines are used to perform a variety of tasks, such as cutting, shaping, and sanding wood.

- There are many different types of woodworking machines, each with its own purpose.

- Some of the most common types of woodworking machines include:

- Table saws

- Miter saws

- Circular saws

- Jigsaws

- Sanders

10. What are the different types of woodworking projects?

- Woodworking projects can range from simple to complex.

- Some of the most common types of woodworking projects include:

- Furniture

- Cabinets

- Toys

- Musical instruments

- Architectural woodwork

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cutter’s primary role is to operate and maintain cutting equipment to cut various materials, ensuring accurate dimensions and quality.

1. Equipment Operation

Operate and maintain cutting machines, such as laser cutters, waterjet cutters, and plasma cutters.

- Set up and calibrate equipment according to specifications.

- Monitor cutting processes and make adjustments as needed.

2. Material Preparation

Prepare materials for cutting, including loading and unloading materials.

- Inspect materials for defects and ensure proper alignment.

- Adjust cutting parameters based on material properties.

3. Quality Control

Inspect cut pieces to ensure they meet dimensional tolerances and quality standards.

- Use measuring tools and gauges to verify accuracy.

- Identify and correct any defects or inconsistencies.

4. Troubleshooting and Maintenance

Troubleshoot and resolve equipment issues to maintain optimal performance.

- Perform routine maintenance and repairs.

- Collaborate with maintenance technicians as needed.

Interview Tips

Preparing for a Cutter interview requires understanding the key job responsibilities and highlighting your relevant skills and experience.

1. Research the Company and Position

Research the company, its industry, and the specific job requirements to tailor your answers and demonstrate your interest.

- Visit the company’s website and review their mission, values, and recent news.

- Check industry publications and websites to stay informed about relevant trends and technologies.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions related to your skills, experience, and motivation.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Practice answering questions aloud to improve your delivery and confidence.

3. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining cutting equipment.

- List your experience with different types of cutting machines, including laser cutters, waterjet cutters, and plasma cutters.

- Describe your skills in setting up, calibrating, and troubleshooting cutting equipment.

4. Demonstrate Your Attention to Detail

Highlight your attention to detail and commitment to quality control.

- Explain your processes for inspecting cut pieces and ensuring dimensional accuracy.

- Provide examples of how you have identified and corrected defects or inconsistencies.

5. Be Prepared to Answer Behavioral Questions

Interviewers often ask behavioral questions to assess your work style and interpersonal skills.

- Think about examples from your previous work experience that demonstrate your teamwork, problem-solving abilities, and customer service skills.

- Use the CAR (Challenge, Action, Result) method to structure your answers and provide specific examples.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!