Feeling lost in a sea of interview questions? Landed that dream interview for Cutter Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cutter Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

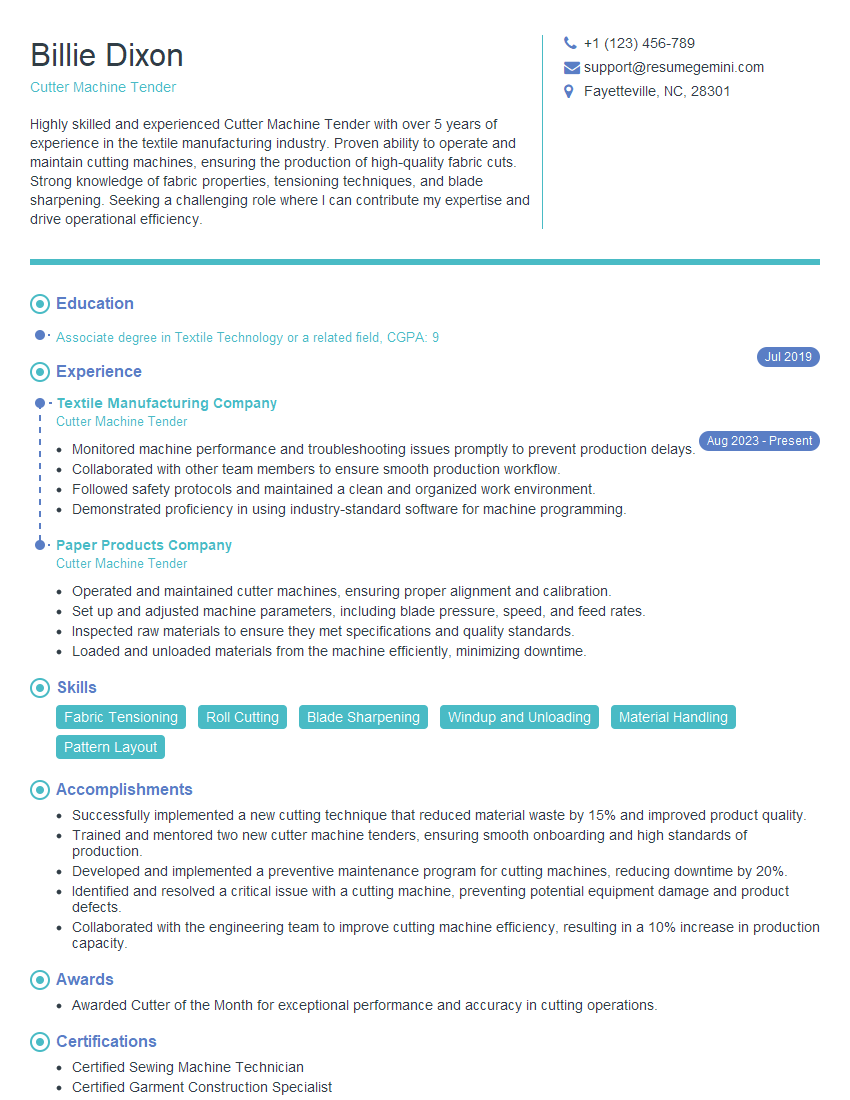

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutter Machine Tender

1. Explain the process of setting up and operating a cutting machine.

The process of setting up and operating a cutting machine involves several steps:

- Material preparation: The operator selects the raw material to be cut and places it on the machine bed.

- Machine setup: The operator enters the cutting parameters, including the cutting speed, feed rate, and depth of cut, into the machine’s controller.

- Tool installation: The operator installs the appropriate cutting tool into the machine’s spindle.

- Machine operation: The operator initiates the cutting process and monitors the machine’s operation.

- Part removal: Once the cutting process is complete, the operator removes the finished part from the machine bed.

2. How do you ensure the accuracy of cuts made on a cutting machine?

Maintaining machine calibration

- Regularly calibrate the machine according to the manufacturer’s specifications.

- Use precision measuring tools to ensure the accuracy of the machine’s movements.

Proper tool selection and maintenance

- Select the appropriate cutting tool for the material being cut.

- Sharpen and replace cutting tools as needed to maintain their accuracy.

Careful material handling

- Secure the material properly on the machine bed to prevent movement during cutting.

- Use clamps or fixtures to hold the material in place.

3. Describe the different types of cutting tools used in cutting machines and their applications.

There are various types of cutting tools used in cutting machines, each designed for specific materials and applications:

- Milling cutters: Used for roughing and finishing operations on a variety of materials, including metals, plastics, and wood.

- Drills: Used for creating holes in various materials.

- Taps: Used for creating threads in holes.

- Reaming tools: Used for enlarging and finishing holes to precise dimensions.

- Broaching tools: Used for creating internal or external shapes in metal components.

4. How do you troubleshoot common problems that occur during the operation of a cutting machine?

- Tool breakage: Inspect the tool for damage or wear, check the cutting parameters, and adjust as necessary.

- Material distortion: Ensure proper material clamping, adjust cutting parameters to reduce heat buildup, and use coolant to prevent thermal distortion.

- Surface finish issues: Check the tool condition, cutting parameters, and machine alignment to identify and resolve the cause of poor surface finish.

- Machine vibration: Inspect the machine for loose components or worn bearings, and perform regular maintenance to minimize vibration.

- Electrical faults: Follow established safety protocols, isolate the machine from power, and consult a qualified electrician for troubleshooting and repairs.

5. What are some safety precautions to observe when operating a cutting machine?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Keep work area clean and free of clutter.

- Secure materials properly before cutting.

- Never leave the machine unattended while it is operating.

- Follow lockout/tagout procedures before performing maintenance or repairs.

6. How do you maintain and calibrate a cutting machine to ensure its optimal performance?

Maintenance

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for wear or damage and replace components as needed.

- Monitor the machine’s performance and adjust cutting parameters to optimize efficiency.

Calibration

- Use precision measuring tools to calibrate the machine’s axes and ensure accuracy.

- Follow the manufacturer’s calibration procedures to adjust the machine’s settings.

- Regularly check the machine’s calibration to maintain its precision.

7. What are the different materials that can be cut using a cutting machine?

Cutting machines are capable of cutting a wide range of materials, including:

- Metals: Steel, stainless steel, aluminum, copper, brass

- Plastics: Acrylic, polycarbonate, PVC, ABS, nylon

- Wood: Hardwoods, softwoods, plywood, MDF

- Composites: Carbon fiber, fiberglass, ceramics

8. How do you determine the appropriate cutting parameters for different materials?

- Refer to manufacturer’s recommendations for specific materials.

- Consider the material’s hardness, toughness, and thickness.

- Experiment with different cutting parameters to determine the optimal settings for the desired cut quality and efficiency.

- Use software or tables that provide recommended cutting parameters based on material properties.

9. What are some quality control measures you can implement to ensure the accuracy and consistency of cut parts?

- Establish and follow documented quality control procedures.

- Use precision measuring tools to inspect the dimensions and tolerances of cut parts.

- Monitor the machine’s performance and make adjustments as needed to maintain accuracy.

- Maintain records of cutting parameters and inspection results for traceability.

10. How do you stay up-to-date with the latest advancements in cutting machine technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical articles.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and user groups.

- Receive training from experienced professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutter Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutter Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutter Machine Tenders are responsible for the efficient and safe operation of cutting machines. They work with various materials, including fabrics, paper, and metals, to create various finished products.

1. Machine Operation

Tenders are responsible for operating cutting machines, such as guillotine cutters, die cutters, and CNC cutters.

- Set up and adjust machines according to job specifications.

- Position and secure materials to be cut.

- Initiate cutting operations and monitor progress.

2. Material Handling

They load and unload materials from the machine, and can move heavy materials around the work area.

- Load and unload materials from cutting machines.

- Move and stack materials safely and efficiently.

3. Quality Control

Tenders inspect materials before and after cutting to ensure that they meet quality standards.

- Inspect materials for defects before cutting.

- Check dimensions and tolerances of cut pieces.

4. Maintenance and Troubleshooting

They maintain and troubleshoot cutting machines to ensure proper operation.

- Perform routine maintenance on cutting machines.

- Troubleshoot and resolve machine problems.

Interview Tips

Preparing for an interview for a Cutter Machine Tender position requires thorough research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Role

Research about the company’s history, products or services, and industry standing.

- Visit the company website and social media pages.

- Read articles and news about the company.

2. Practice Your Answers

Prepare for common interview questions and practice answering them clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your skills and experiences relevant to the role.

3. Showcase Your Technical Knowledge

Demonstrate your understanding of cutting machines, their operation, and maintenance.

- Describe your experience operating different types of cutting machines.

- Explain how you troubleshoot and resolve machine problems.

4. Emphasize Your Safety Awareness

Emphasize your understanding and commitment to safety practices in a manufacturing environment.

- Describe your experience following safety protocols and procedures.

- Explain how you prioritize safety in your work.

5. Be Confident and Enthusiastic

Approach the interview with confidence and enthusiasm. Demonstrate your interest in the role and your eagerness to contribute to the company.

- Maintain eye contact, smile, and speak clearly.

- Show your enthusiasm for the industry and the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cutter Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.